marrenmiller

Basic Member

- Joined

- Apr 6, 2017

- Messages

- 1,791

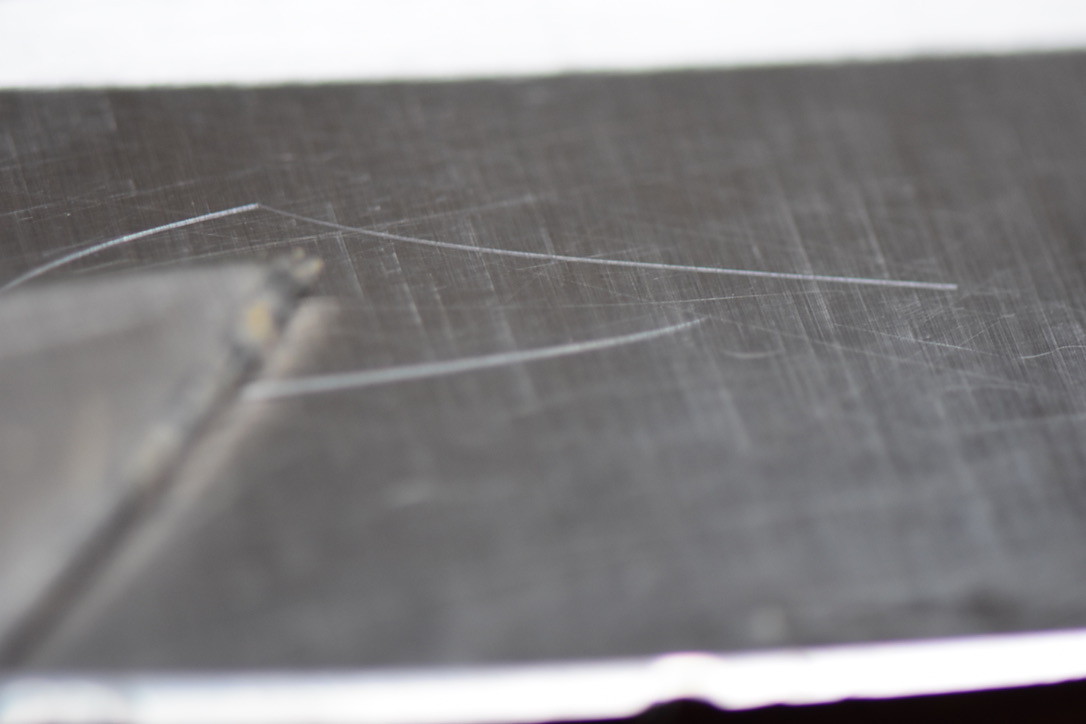

I read that before, yeah. This doesn't behave like anything that's anywhere near that hard. I hope I'm wrong but I don't think I am in this case. But that is definitely the right process per AKS to get somewhere in the 62 HRC range.No idea man. I have a HB03 in M390 love it no issues here with the heat treatment or overheated edge. The S125V being completely different could have been overheated during grinding given its tough to machine.

Here is their heat treat specs for it if you’ve not saw already.

To yield the maximum performance from the alloy Fantoni utilizes an exacting heat treating process. First the steel is brought up to 2050ºF (1121ºC) (Austenite) with a 15 minute hold to homogenize the material. An inert gas quench is executed to avoid surface oxidation. It is then processed through a freezing treatment of -176ºF (-80ºC) for three hours to maximize the transformation from an Austentic to Martensitic phase. Finally two complete tempering procedures bringing the blades up to 356ºF (180ºC) for three hours and back down to room temperature results in the final hardness of 61-62 Rockwell.

Last edited: