-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fiddleback Handmade

- Thread starter ChoBro

- Start date

- Joined

- Mar 13, 2006

- Messages

- 13,878

here's a very informative postPlease direct me to posts about how Handmade Fiddlebacks are made. Thanks, I can't find it.

https://www.bladeforums.com/threads...the-knives-are-made-very-photo-heavy.1237809/

- Joined

- Mar 13, 2006

- Messages

- 13,878

Whelp ChoBro, it seems the image links are not working correctly. they are not loading correctly for me.Thank you very much!

Chobro

sorry about that

edit

upon further investigation, it seems the pics are being held ransom by photobucket

swonut

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 1, 2007

- Messages

- 1,434

If you search the Fiddleback forum for "behind the scenes" you'll see lots of shop pictures and can probably find examples of all these steps. The process is roughly.

- Draw out knife profile on steel

- Grind out the profile.

- Drill Handle holes

- Rough Grind blade edge

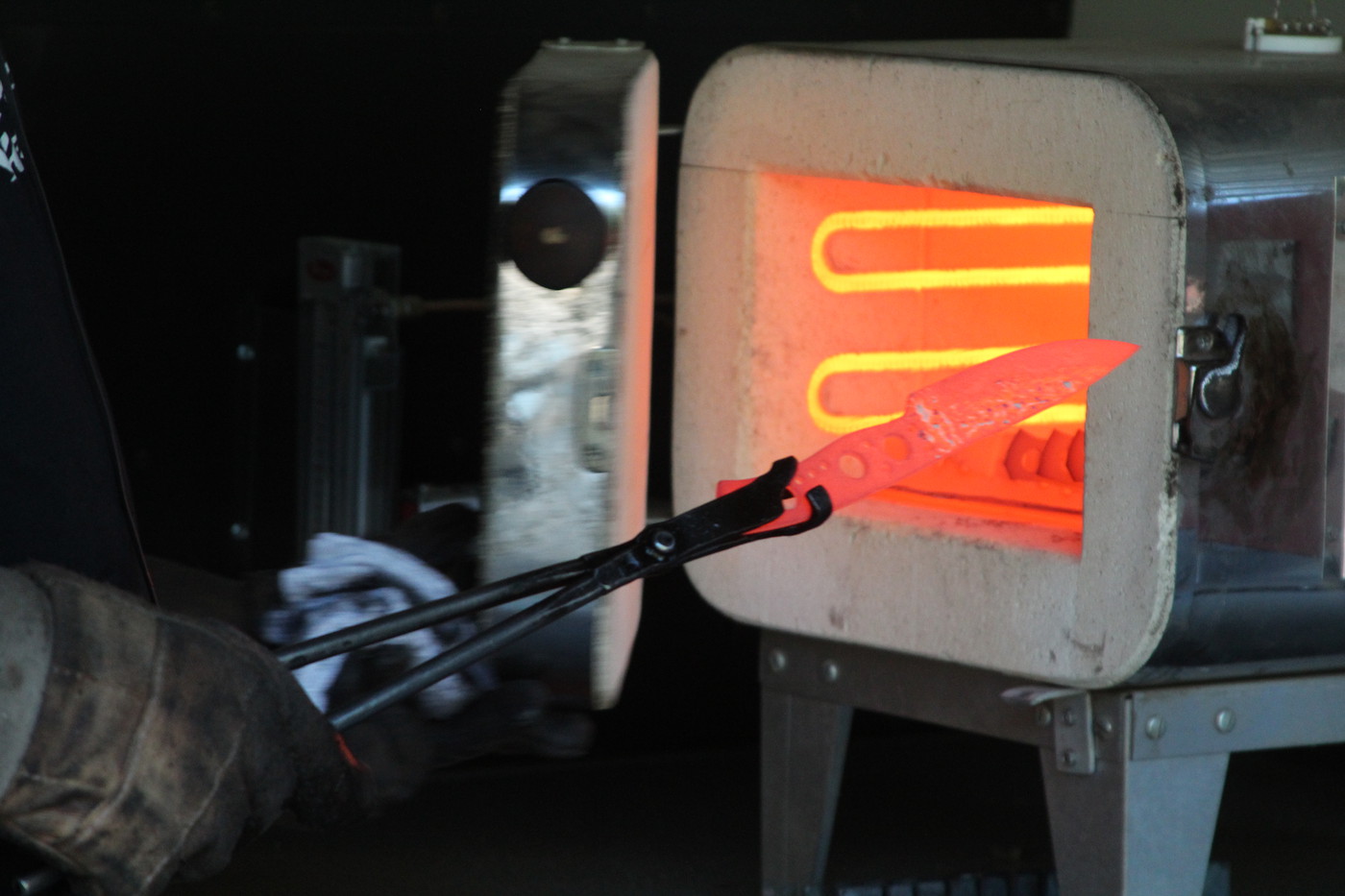

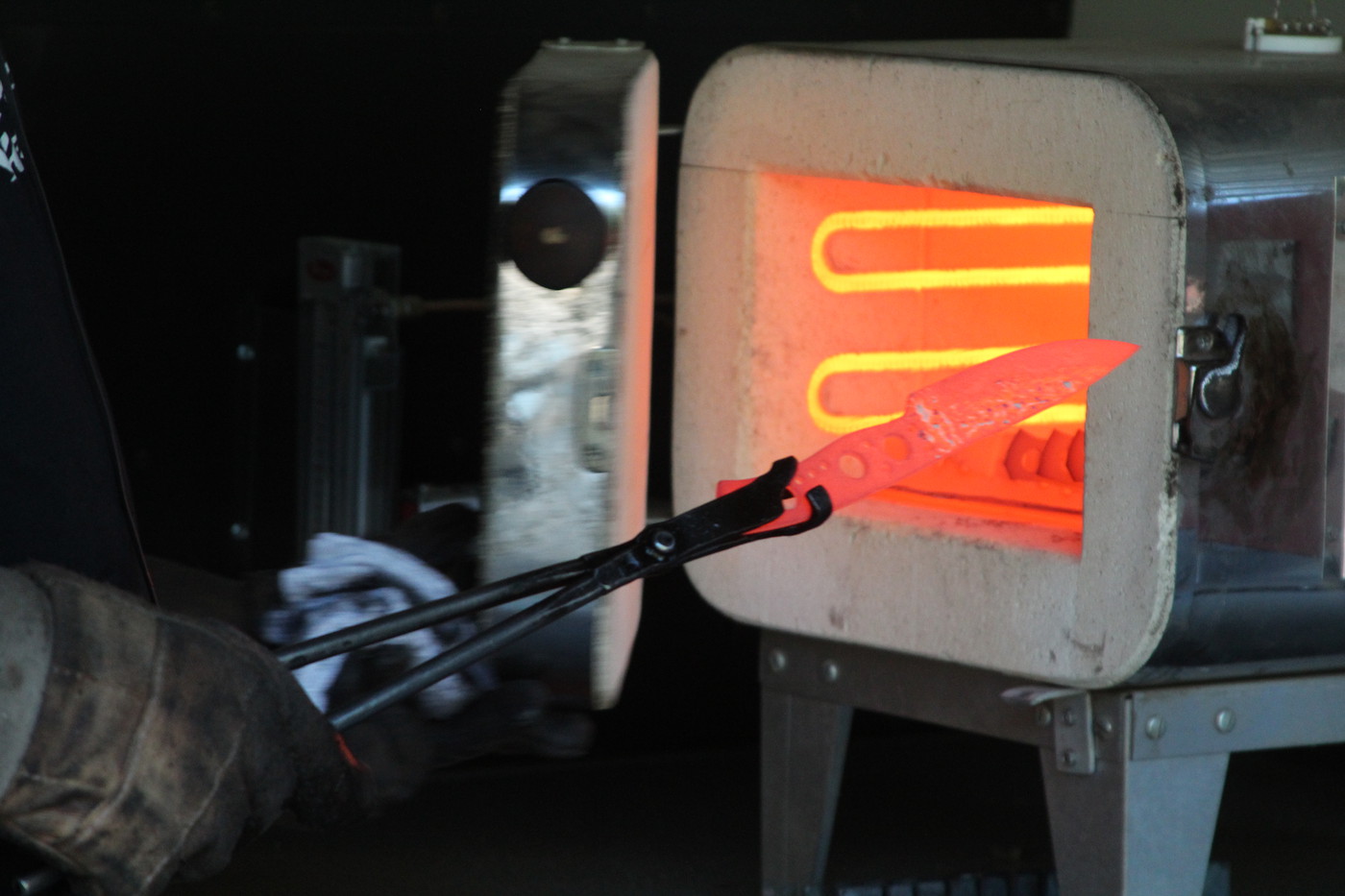

- Heat Treat

- Attach Handle

- final Grind of blade

- Handle rough Shape

- Handle hand sand

- Mail.

The handle sales get a process of:

Select material and backing

Epoxy into two blanks

Epoxy to blade with pins and tubes.

- Draw out knife profile on steel

- Grind out the profile.

- Drill Handle holes

- Rough Grind blade edge

- Heat Treat

- Attach Handle

- final Grind of blade

- Handle rough Shape

- Handle hand sand

- Mail.

The handle sales get a process of:

Select material and backing

Epoxy into two blanks

Epoxy to blade with pins and tubes.

- Joined

- Mar 13, 2006

- Messages

- 13,878

cliff notes version of the link in posted..

scribe pattern on steel

grind to the "line" the scribe produced

drill holes for pins & Bullseye

pre heat treat grinds

heat treat

laminate scales to liners & pinstripes

match knife to scales & drill the holes

remove excess scale material

glue scales on

clamp scales over night

shape scales

here is where we hand sand the handle. i have no pics because I cant do both at the same time

Andy will put the finish grinds on

With any luck, you will see one you want like this on a Friday

Hope that helps

scribe pattern on steel

grind to the "line" the scribe produced

drill holes for pins & Bullseye

pre heat treat grinds

heat treat

laminate scales to liners & pinstripes

match knife to scales & drill the holes

remove excess scale material

glue scales on

clamp scales over night

shape scales

here is where we hand sand the handle. i have no pics because I cant do both at the same time

Andy will put the finish grinds on

With any luck, you will see one you want like this on a Friday

Hope that helps

- Joined

- May 7, 2012

- Messages

- 4,971

Awesomeness.

I suppose this leads to enough variation in one model alone, it's worth getting several of a favorite to fine tune the perfect fit.

I suppose this leads to enough variation in one model alone, it's worth getting several of a favorite to fine tune the perfect fit.

- Joined

- Nov 13, 2013

- Messages

- 2,166

Awesomeness.

I suppose this leads to enough variation in one model alone, it's worth getting several of a favorite to fine tune the perfect fit.

Yes, I'd shoot for 5 of each model in various steel thicknesses, handles, tapered and full tangs. And of course one user when you find that right fit so you can be sure to have one to throw dirt on to show the hardcore knaf users

- Joined

- Apr 24, 2012

- Messages

- 3,850

Hey Justin, you're exactly right! To have a little fun here, let's take a look at different angles comparing 3 Bushfingers.Awesomeness.

I suppose this leads to enough variation in one model alone, it's worth getting several of a favorite to fine tune the perfect fit.

Where you'll see definite consistency is in the profile silhouette. Take away the silhouette aspect and the blade could be convex grind or scandi grind. Within convex grinds, it could be a super high grind, lower grind or somewhere between.

.

Scale material aside, take a moment to pick which handle you think you might like best.

.

After you made a selection, scroll down.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Surprise!

.

Among the three, one is 3/32", one is 1/8" and one is 5/32". Can you guess steel widths from this angle?

Or this angle? Note in these two butt-end shots how much different they appear from each other vs when you saw them in the first picture.

.

.

.

Continue scrolling down to see the steel thicknesses.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

And here are your spine shots, steel widths and additional differences in handle contours.

The top one is 5/32" TT

The middle one is 1/8" TT

And the bottom one ends up with the widest / most roundish handle along with 3/32" SFT.

At this point, there is no good or bad, right or wrong .. there is only user preference to decide which each person likes best. A wider handle and wider blade stock is likely going to be more comfy for extended use, especially with bushcrafting. I happen to prefer the middle knife handle the best because the handle is narrower and has a nice pinch grip with a little flare up front. The 1/8" TT and 5/32" TT have pretty similar measurements at the pinch grip but the 5/32" TT doesn't flare as much up front. To someone else, the 1/8" TT specimen might be their least favorite. Taken further, some folks absolutely love full tang, some absolutely love tapered tang and some might not even notice if there's a taper or not.

So yes! Buy a few (or as Danny said) 5 of each

Choppaman

Gold Member

- Joined

- May 6, 2017

- Messages

- 7,137

Great job guys!! if I didn't know, I would know now!!

ChoBro, the other thing to consider is the friendship you develop with the entire knife community that surrounds Fiddleback Forge and WASurls. Andy/Allen are great peeps and if you need anything you can expect the knife community to answer here (as witnessed above). Phillip is the man and Robert at the outpost is a huge help. This family goes a bit further than that as well. Upcoming talents like Kyle and Cody!!! PLUS other master knife makers like Chris @ Osprey, Adam @ AA Forge OH MAN!!! the list of awesomeness goes on and on!! Just felt like throwing that in there!

ChoBro, the other thing to consider is the friendship you develop with the entire knife community that surrounds Fiddleback Forge and WASurls. Andy/Allen are great peeps and if you need anything you can expect the knife community to answer here (as witnessed above). Phillip is the man and Robert at the outpost is a huge help. This family goes a bit further than that as well. Upcoming talents like Kyle and Cody!!! PLUS other master knife makers like Chris @ Osprey, Adam @ AA Forge OH MAN!!! the list of awesomeness goes on and on!! Just felt like throwing that in there!

- Joined

- Feb 1, 2012

- Messages

- 11,783

Awesomeness.

I suppose this leads to enough variation in one model alone, it's worth getting several of a favorite to fine tune the perfect fit.

You said it! And, then, Jerry posted this:

Hey Justin, you're exactly right! To have a little fun here, let's take a look at different angles comparing 3 Bushfingers.

Wow, Jerry. Just Wow. What a great visual summary of exactly What-- Why!-- How!!!! different examples of the 'same' pattern can feel so very different in hand. Your pictures are worth a thousand words, but your words draw out the similarities and divergences so very well.

As you've alluded to, any of the handles you've pictured (and by 'handles' I'm speaking specifically of the contoured Shadetree pieces), could be found adorning any of the steel widths/treatments. Each knife is truly unique.

C ChoBro , also? Once you've handled a view of the knives, you will be better able to gauge via spine shots and other pictured angles what you may or may not prefer in a given example. But leave room for surprises....

And of course,

~ P.

Last edited:

- Joined

- May 7, 2012

- Messages

- 4,971

Yes, I'd shoot for 5 of each model in various steel thicknesses, handles, tapered and full tangs. And of course one user when you find that right fit so you can be sure to have one to throw dirt on to show the hardcore knaf users

5 is a lot, I have 15 models of interest. Plus almost all my knives are used for hardcore use. Primary use is looking at them.

- Joined

- May 7, 2012

- Messages

- 4,971

Hey Justin, you're exactly right! To have a little fun here, let's take a look at different angles comparing 3 Bushfingers.

Where you'll see definite consistency is in the profile silhouette. Take away the silhouette aspect and the blade could be convex grind or scandi grind. Within convex grinds, it could be a super high grind, lower grind or somewhere between.

.

Scale material aside, take a moment to pick which handle you think you might like best.

.

After you made a selection, scroll down.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Surprise!

.

Among the three, one is 3/32", one is 1/8" and one is 5/32". Can you guess steel widths from this angle?

Or this angle? Note in these two butt-end shots how much different they appear from each other vs when you saw them in the first picture.

.

.

.

Continue scrolling down to see the steel thicknesses.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

And here are your spine shots, steel widths and additional differences in handle contours.

The top one is 5/32" TT

The middle one is 1/8" TT

And the bottom one ends up with the widest / most roundish handle along with 3/32" SFT.

At this point, there is no good or bad, right or wrong .. there is only user preference to decide which each person likes best. A wider handle and wider blade stock is likely going to be more comfy for extended use, especially with bushcrafting. I happen to prefer the middle knife handle the best because the handle is narrower and has a nice pinch grip with a little flare up front. The 1/8" TT and 5/32" TT have pretty similar measurements at the pinch grip but the 5/32" TT doesn't flare as much up front. To someone else, the 1/8" TT specimen might be their least favorite. Taken further, some folks absolutely love full tang, some absolutely love tapered tang and some might not even notice if there's a taper or not.

So yes! Buy a few (or as Danny said) 5 of each

Outstanding post. Thank you Sir. I will be honest, that is more variation than I expected!

- Joined

- Apr 24, 2012

- Messages

- 3,850

Thanks and no problem. Please note that I've had a good number of duplicates across a good number of models and they usually don't vary that much. That was the most variation I've seen so thought I ought to take pics while I had them. The main point was that the starting template/blank is the same and then since they're hand made, they can vary. Also if you get a first of a model and it doesn't agree with your hands, try not to dismiss that model because you could very well get another and have it end up being your most favorite.Outstanding post. Thank you Sir. I will be honest, that is more variation than I expected!

- Joined

- May 7, 2012

- Messages

- 4,971

Thanks and no problem. Please note that I've had a good number of duplicates across a good number of models and they usually don't vary that much. That was the most variation I've seen so thought I ought to take pics while I had them. The main point was that the starting template/blank is the same and then since they're hand made, they can vary. Also if you get a first of a model and it doesn't agree with your hands, try not to dismiss that model because you could very well get another and have it end up being your most favorite.

Hmmmm. This is a good point. The primary method I'm using to determine suitability is my preferred blade profile, and the in hand feel. Though I suspect I wouldn't remove one from the possible pool for being too thin or thick based on this information.

In general are there any predictable trends, like wood is generally narrow, micarta is thicker?

- Joined

- Apr 24, 2012

- Messages

- 3,850

Not that I know of. You could also get something commando with no liners or stripes or there could be thicker liners/stripes. It's like a box of chocolatesHmmmm. This is a good point. The primary method I'm using to determine suitability is my preferred blade profile, and the in hand feel. Though I suspect I wouldn't remove one from the possible pool for being too thin or thick based on this information.

In general are there any predictable trends, like wood is generally narrow, micarta is thicker?

- Joined

- May 7, 2012

- Messages

- 4,971

Hmmm. So basically narrow down profile preference, then buy a bunch of them.

The first one I'm lookin for is one to keep near the wood fireplace this fall/winter for processing a little kindling and making a few shavings to get the party started And teach my son. Don't want to use folders as I don't want him to use folders yet.

So in the past few weeks I've bought:

Babyboot,

Runt,

Bear cub,

Bushcrafter,

Bushcrafter Sr (not in hand yet)

Drop Point Renegade

Surls Huntsman

Already had a Recluse.

So far there is something about all of them I'd like to change when it comes to using them for something other than looking at.

One of the patterns I'd love to try next is a EDK or a Hiking Buddy.

The first one I'm lookin for is one to keep near the wood fireplace this fall/winter for processing a little kindling and making a few shavings to get the party started And teach my son. Don't want to use folders as I don't want him to use folders yet.

So in the past few weeks I've bought:

Babyboot,

Runt,

Bear cub,

Bushcrafter,

Bushcrafter Sr (not in hand yet)

Drop Point Renegade

Surls Huntsman

Already had a Recluse.

So far there is something about all of them I'd like to change when it comes to using them for something other than looking at.

One of the patterns I'd love to try next is a EDK or a Hiking Buddy.

- Joined

- Mar 13, 2006

- Messages

- 13,878

when Allen cuts the raw material on the table saw, he has a exact thickness that he cuts them to. the rest is on how Andy shapes them.Not that I know of. You could also get something commando with no liners or stripes or there could be thicker liners/stripes. It's like a box of chocolates

VANCE Would you say that all the scales start out at the same general thickness and then it depends on how much time there is spent against a sanding belt? Or do some materials start with thinner out thicker scales?

ShanghaiJer

Gold Member

- Joined

- Apr 3, 2014

- Messages

- 1,813

One of the patterns I'd love to try next is a EDK or a Hiking Buddy.

I love my EDK. I can see how it wouldn't be for everyone though, but it works for me.

Last edited:

- Joined

- Mar 13, 2006

- Messages

- 13,878

i sent you one of my EDK's with your shipment this week. It's been all over the place. It's been on tour w/ moe.One of the patterns I'd love to try next is a EDK or a Hiking Buddy.