-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fifteen degree edge?

- Thread starter Naphtali

- Start date

So a consensus for a hunting/outdoor fixed bladed knife that uses a high-quality steel - the new term may be "premium steel??" - where the blade will have hard, but not abusive, use is 15 degrees DPS? And while such steels are capable of finer edges, such edges may have durability issues were knife use to include more than slicing?

- Joined

- Mar 7, 2001

- Messages

- 4,608

@philwar,

There's a thread about D2 somewhere around M T & E subforum. I have only one sample and the advice I get from maker is 30° inclusive and 600 DMT is best. I'm still testing and trying to go higher but the apex seems to degrade quickly to working edge that's almost similar to finishing on 600.

@ OP,

Sorry to derail the thread. D2 is known for the 'working edge' characteristics as opposed to high sharpness. Some makers can really bring D2's qualities very well, such as Bob Dozier. I never try one, but heard on the forum that his knives are well suited for hunting, etc. It might be the HT, geometry and the finish he puts.

There's a thread about D2 somewhere around M T & E subforum. I have only one sample and the advice I get from maker is 30° inclusive and 600 DMT is best. I'm still testing and trying to go higher but the apex seems to degrade quickly to working edge that's almost similar to finishing on 600.

@ OP,

Sorry to derail the thread. D2 is known for the 'working edge' characteristics as opposed to high sharpness. Some makers can really bring D2's qualities very well, such as Bob Dozier. I never try one, but heard on the forum that his knives are well suited for hunting, etc. It might be the HT, geometry and the finish he puts.

Last edited:

- Joined

- Jun 4, 2010

- Messages

- 6,642

So a consensus for a hunting/outdoor fixed bladed knife that uses a high-quality steel - the new term may be "premium steel??" - where the blade will have hard, but not abusive, use is 15 degrees DPS? And while such steels are capable of finer edges, such edges may have durability issues were knife use to include more than slicing?

In my experience 15° is about perfect for general or hard use. Anything more obtuse doesn't give enough longevity to make up for the decrease in performance, and anything more acute can suffer from lateral stability issues.

If using stuff like s30, 60, 90, 110v you could likely go progressively thinner and the steel is so tough it will still hold up, you are also removing the margin of error. For dedicated work under controlled conditions you could drop down to 12° or so/side and still get good life from the tool.

As for the D2, I have taken samples lower than 15°/side and it held up in general, Chris' observations that it just doesn't hold the fine edge for very long mirror my own. I do find by thinning it down to just under 15° I get a better mix of push and draw even after the edge wears in a bit. I wouldn't go below 12-13°/side though as the carbides really are massive and need a good anchor point with the steel if they're going to last.

Many thanks for your replies, guys.

I guess the old saw, "In for a dime, in for a dollar," fits my follow-up. Are there particularly efficient manual diamond sharpening systems - systems rather than merely stones - you recommend and/or prefer? When I realized that this is an opportunity to obtain an advanced system to maintain knives I own or will own in the reasonable future, my examining literature and advertising for these systems identified costs from $80.00 to more than $300.00. While I don't blanch at $300.00, I have no idea whether such a system (Wicked Edge Field and Sport) is worth its substantial premium price, both in terms of efficiency and precision, when compared with systems such as Gatco and Lansky's.

I guess the old saw, "In for a dime, in for a dollar," fits my follow-up. Are there particularly efficient manual diamond sharpening systems - systems rather than merely stones - you recommend and/or prefer? When I realized that this is an opportunity to obtain an advanced system to maintain knives I own or will own in the reasonable future, my examining literature and advertising for these systems identified costs from $80.00 to more than $300.00. While I don't blanch at $300.00, I have no idea whether such a system (Wicked Edge Field and Sport) is worth its substantial premium price, both in terms of efficiency and precision, when compared with systems such as Gatco and Lansky's.

What is EPA??There's diamond stones for EPA. I use 'm.

- Joined

- Mar 16, 2013

- Messages

- 2,239

What type of steel? And what are you cutting resulting in chipping?For me, 15 per side chips too easily. Just my experience.

My bk9 is 15dps and with all the chopping, batoning, and such I've experienced no negative effects. My work beater schrade schf14 which is 8cr13mov and it'll even hold 15dps unless I hit staples in boxes, but a micro bevel helped a lot with that.

This.

440A requires a steeper bevel or microbevel as well.

Randall's 440B will hold around 12 degree per side while chopping over hundreds of chops... Some 440C will chip and some will not. 440C is all over the place in terms of wood chopping integrity at very closed angles (20-24 degrees inclusive): Some makers do well, some don't. Lile's D-2 is excellent even at 24 degree inclusive while chopping wood, and this across two knives from this maker. Randall's 440B is truly remarkable on my Model 12 at under 25 degrees inclusive, 0-1 outstanding on my Model 18 at 20 degrees inclusive (but lower chopping impact on such a lighter blade). My 440B of my Model 14 chipped out however, despite the light hitting blade, when brought down to around 20 degrees inclusive: It probably would have held at around 24 degrees inclusive...

Gaston

chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

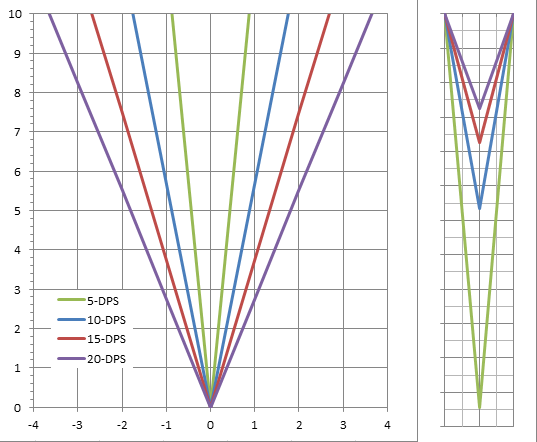

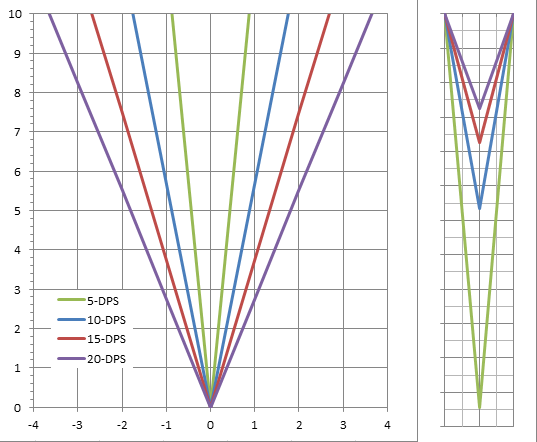

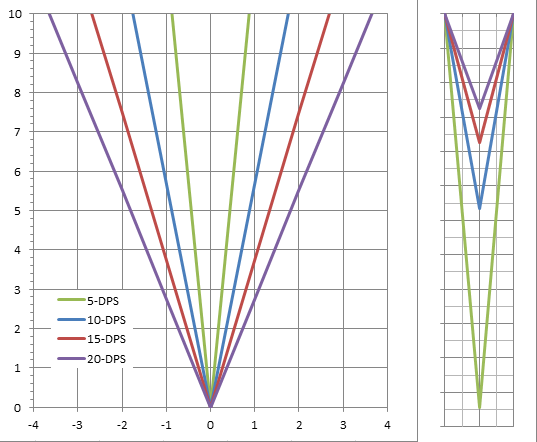

I've posted these elsewhere, but here they are for reference:

Edge Angles:

Comparison of a few knives all sharpened to 30-inclusive except the red box-cutter blade that is <20:

Like Joe Calton mentioned in his review, it is VERY important to discuss not just angle but THICKNESS. Axes and wood-chippers and lawn-mowers and even razor-blades commonly use a 30-inclusive edge angle, but apex-diameter (how refined that 30-inclusive is) and thickness behind the edge determine its utility, not that angle. An axe is not normally ground to <1 micron apex diameter at high grit, there is no need for that level of precision on such a tool, but it DOES require a thickness behind the edge suitable to support that edge. When Joe mentions 0.020" thick for chopping bone, that is roughly comparable to the green blade in the diagram above. 0.020" is common on many folding knives and small fixed blades.

The yellow blade is a slicer measured at 0.005" behind the edge when that diagram was made, MUCH too thin for most chopping tasks, but stronger near the apex than the box-cutter yet thinner than the box-cutter for a significant region behind the apex.

Discussing suitability of geometry without discussing behind-the-edge thickness is ignoring the most significant aspect of that geometry.

Edge Angles:

Comparison of a few knives all sharpened to 30-inclusive except the red box-cutter blade that is <20:

Like Joe Calton mentioned in his review, it is VERY important to discuss not just angle but THICKNESS. Axes and wood-chippers and lawn-mowers and even razor-blades commonly use a 30-inclusive edge angle, but apex-diameter (how refined that 30-inclusive is) and thickness behind the edge determine its utility, not that angle. An axe is not normally ground to <1 micron apex diameter at high grit, there is no need for that level of precision on such a tool, but it DOES require a thickness behind the edge suitable to support that edge. When Joe mentions 0.020" thick for chopping bone, that is roughly comparable to the green blade in the diagram above. 0.020" is common on many folding knives and small fixed blades.

The yellow blade is a slicer measured at 0.005" behind the edge when that diagram was made, MUCH too thin for most chopping tasks, but stronger near the apex than the box-cutter yet thinner than the box-cutter for a significant region behind the apex.

Discussing suitability of geometry without discussing behind-the-edge thickness is ignoring the most significant aspect of that geometry.

Fred.Rowe

Knifemaker / Craftsman / Service Provider

- Joined

- May 2, 2004

- Messages

- 6,848

I've posted these elsewhere, but here they are for reference:

Edge Angles:

Comparison of a few knives all sharpened to 30-inclusive except the red box-cutter blade that is <20:

Like Joe Calton mentioned in his review, it is VERY important to discuss not just angle but THICKNESS. Axes and wood-chippers and lawn-mowers and even razor-blades commonly use a 30-inclusive edge angle, but apex-diameter (how refined that 30-inclusive is) and thickness behind the edge determine its utility, not that angle. An axe is not normally ground to <1 micron apex diameter at high grit, there is no need for that level of precision on such a tool, but it DOES require a thickness behind the edge suitable to support that edge. When Joe mentions 0.020" thick for chopping bone, that is roughly comparable to the green blade in the diagram above. 0.020" is common on many folding knives and small fixed blades.

The yellow blade is a slicer measured at 0.005" behind the edge when that diagram was made, MUCH too thin for most chopping tasks, but stronger near the apex than the box-cutter yet thinner than the box-cutter for a significant region behind the apex.

Discussing suitability of geometry without discussing behind-the-edge thickness is ignoring the most significant aspect of that geometry.

The discussion should always start with the geometry of a blade. Once you figure out if its an expensive Gato or a splitting maul, then you can decide what edge is appropriate for the tool.