- Joined

- Sep 30, 2012

- Messages

- 15,381

I thought id share my experiences while learning to make my first knife.

I ordered a craftsman 2x42, But when it arrived it was defective. The belt rubbed on the casing a lot, and once i got the belt able to pass through it bounced around on the platen. Tracking wasnt great either. But i could of dealt with everything else except the belt bouncing all over the place. I returned it to sears, but i have to wait on the refund before i can order the new one.

My work area. The grinder will go on the first table once it gets here.

Some tools, etching kit, and other odds and ends. Most of this i have received in the last several days to a week. I had to finance the majority of it, but its already worth it as im enjoying every minute of it.

My new HF drill press and some Tap Magic oil

Some belts for the grinder. Ceramic, Zirconia, And Trizacts "gators"

I couldnt even wait on the new grinder to start, so im using a hacksaw, drill, and files to start my first small knife now... Nothing fancy but im enjoying the process even using mostly hand tools.

1/8" O1 tool steel, 8 1/4" OAL... I call it the "Woody Pecker"

Basic design drawn out,

Added a little curvature to the spine and dropped the point a bit using files.

Drilled some holes and starting sawing with the hacksaw...

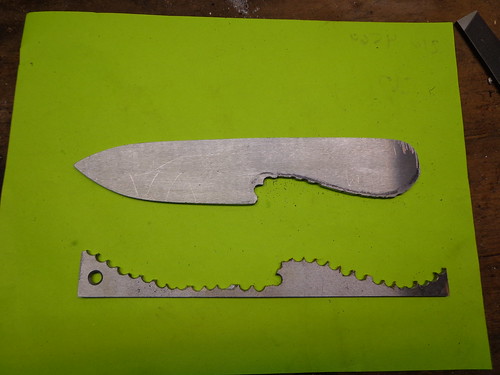

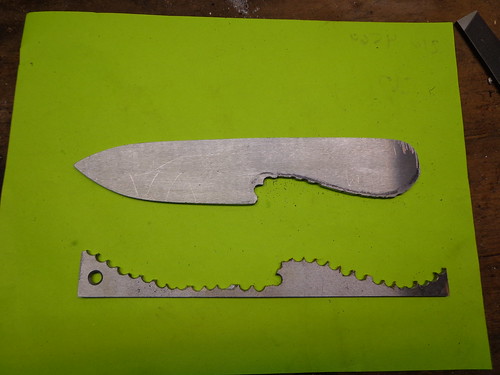

Got the bugger cut out...

Started filing the ridges down and smoothing it out....

Had to reduce the palm swell to make it more comfortable in the hands. finished up the profile in 24 hours working on and off... Ok mostly on because i just couldnt stop until i had the profile shaped

I know its nothing amazing, but i have to start somewhere!

I may wait on the grinder to add the bevels and edge, i still need to get a center scribe as well. So it may take me a bit to progress further.

And here i am practicing etching my "logo". Im using electrical etching, but i may also try PCB soon as well and see if i can get it even better.

Id like to thank the guys here on BF for the encouragement, and all the helpful information they post that help make this easier on a newbie like me.

Thanks everyone for looking. I will update as i progress further.

Richard

I ordered a craftsman 2x42, But when it arrived it was defective. The belt rubbed on the casing a lot, and once i got the belt able to pass through it bounced around on the platen. Tracking wasnt great either. But i could of dealt with everything else except the belt bouncing all over the place. I returned it to sears, but i have to wait on the refund before i can order the new one.

My work area. The grinder will go on the first table once it gets here.

Some tools, etching kit, and other odds and ends. Most of this i have received in the last several days to a week. I had to finance the majority of it, but its already worth it as im enjoying every minute of it.

My new HF drill press and some Tap Magic oil

Some belts for the grinder. Ceramic, Zirconia, And Trizacts "gators"

I couldnt even wait on the new grinder to start, so im using a hacksaw, drill, and files to start my first small knife now... Nothing fancy but im enjoying the process even using mostly hand tools.

1/8" O1 tool steel, 8 1/4" OAL... I call it the "Woody Pecker"

Basic design drawn out,

Added a little curvature to the spine and dropped the point a bit using files.

Drilled some holes and starting sawing with the hacksaw...

Got the bugger cut out...

Started filing the ridges down and smoothing it out....

Had to reduce the palm swell to make it more comfortable in the hands. finished up the profile in 24 hours working on and off... Ok mostly on because i just couldnt stop until i had the profile shaped

I know its nothing amazing, but i have to start somewhere!

I may wait on the grinder to add the bevels and edge, i still need to get a center scribe as well. So it may take me a bit to progress further.

And here i am practicing etching my "logo". Im using electrical etching, but i may also try PCB soon as well and see if i can get it even better.

Id like to thank the guys here on BF for the encouragement, and all the helpful information they post that help make this easier on a newbie like me.

Thanks everyone for looking. I will update as i progress further.

Richard

Last edited: