-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First time making a knife WIP

- Thread starter worldwood

- Start date

- Joined

- Sep 30, 2012

- Messages

- 15,381

I don't know what size you're looking at, but 4 oz. of T-88 shouldn't be much more than $15 iirc and goes a looong way.

Ok yea... I guess i should of said its expensive compared to JB Weld or loctite

Not that 15 bucks is a WHOLE LOT of money... But 15 bucks here 20 bucks there 17 bucks over there.. ETC. Adds up real quick.

But if this is whats needed ill make it happen!!

I use west systems g-flex, both to attach scales and dab the holes/smear the pin as I push it in. Let everything cure properly then nip the pins flush with either an angle grinder or cable cutter, the rest is back to the belt and sandpaper.

Ill probably use a hacksaw to cut the pins close to size and then file them down.. Thats the plan anyways.

- Joined

- Apr 20, 2013

- Messages

- 7,205

Ok yea... I guess i should of said its expensive compared to JB Weld or loctite

Not that 15 bucks is a WHOLE LOT of money... But 15 bucks here 20 bucks there 17 bucks over there.. ETC. Adds up real quick.

But if this is whats needed ill make it happen!!

OK, my bad, it was $18.39, but I probably bought it when it was on sale or I had a coupon.

Ill probably use a hacksaw to cut the pins close to size and then file them down.. Thats the plan anyways.

One way you'll know if your pins are in there good is if when you start to belt sand them flush they don't pop out the other side. That's how I ended up doing mine again with the file groove trick and T-88. The scales were epoxied on with it, but after waiting two days to get the scales glued up (I know, I went about it totally bass ackwards

- Joined

- Sep 30, 2012

- Messages

- 15,381

Yea i was looking at the "System Three T-88 High performance Epoxy, 1/2 Pint Kit" for 19.95

but i guess its worth it if the bottles last a while.

The JB Weld at 3-4 bucks in the store up the road sounded much friendlier though LOL

But i do want the handle to stay together so ill try and control my cheap urges

but i guess its worth it if the bottles last a while.

The JB Weld at 3-4 bucks in the store up the road sounded much friendlier though LOL

But i do want the handle to stay together so ill try and control my cheap urges

- Joined

- Sep 30, 2012

- Messages

- 15,381

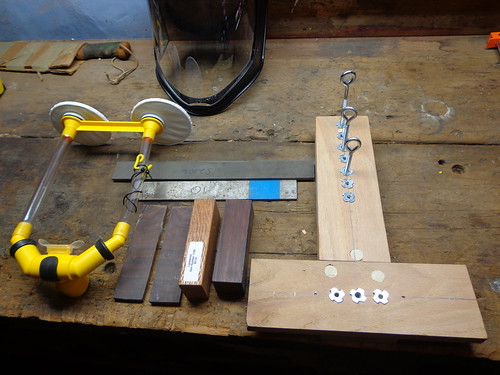

File jig, few blocks of wood, resp-o-rator, couple chunks of steel, heavy duty clamp, 60 grit sanding drums for the dremel, and some thread tape received.

T-88 epoxy has been ordered. 1/2 pint kit

10 feet of 1/8" brass rods has been ordered. Pack of 10- 1 foot long pieces was only 13 bucks.

8 feet of 1/8" 52100 has been ordered.

12 pack of chainsaw files has been ordered.

12" double cut bastard file has been ordered.

3/8" X 36" steel rod has been ordered.

Nobody tell my wife

T-88 epoxy has been ordered. 1/2 pint kit

10 feet of 1/8" brass rods has been ordered. Pack of 10- 1 foot long pieces was only 13 bucks.

8 feet of 1/8" 52100 has been ordered.

12 pack of chainsaw files has been ordered.

12" double cut bastard file has been ordered.

3/8" X 36" steel rod has been ordered.

Nobody tell my wife

- Joined

- May 8, 2014

- Messages

- 36

Nice work so far. Will be nice to see completed blade. I look forward to it.

Right now i do not have a belt grinder to use i just started making knives about 4 to 5 months ago and so far I have a jig saw, an angle grinder and a vice clamp thats about it for making my knives. Im going to try and get some more equipment so I can make better looking knives soon. I have some I have made with just these materials in the gallery you can check out.

BTW what does swamp rat brotherhood and beckerhead come from? are these knife making groups? if so can I join?

Thanks,

Tyler Jacobs

Right now i do not have a belt grinder to use i just started making knives about 4 to 5 months ago and so far I have a jig saw, an angle grinder and a vice clamp thats about it for making my knives. Im going to try and get some more equipment so I can make better looking knives soon. I have some I have made with just these materials in the gallery you can check out.

BTW what does swamp rat brotherhood and beckerhead come from? are these knife making groups? if so can I join?

Thanks,

Tyler Jacobs

- Joined

- Sep 30, 2012

- Messages

- 15,381

Thank you Jacobs.

SO far im really enjoying the knife making processes and find using files much easier to get better results. The grinder takes more practice. I have a bunch of steel on the way and i will be using it to mainly practice doing bevels. Thats the hard part for me so far. Getting them profiled out is not as difficult. The smaller knife is ready to go to heat treat. Then i will add scales and finish cleaning it up and put on the edge.

I used a chainsaw file to add a sharpening notch choil on this one, worked great and only took a couple minutes, and that was going slow to make sure i kept it straight and even and where i wanted it.

As far as the swamp rat brotherhood and Beckerheads these are both groups for manufactured knives. Beckerheads are a group of fans for the Ka-Bar Beckers. And Swamp Rat is a company in the Busse family. The SR Brotherhood is a fairly new thing, we came up with a brotherhood knife on the SR Rat chat forum. There is not much to it, other than a group of us loyal fans that really enjoy the knives.

For becoming a Beckerhead there are different things you must accomplish in order to do so. You can check out the Becker subforum and get all the information if your interested, or let me know and i can send you an email.

Neither have to do with knife making though. Im newer to this than you if you been doing it a few months. I just started when i started this thread LOL. So i been in it for 10 days now. But im hooked. And will continue to practice and keep on making knives as time allows. Right now my kids are out of school today and tomorrow so i havent had a lot of time to play around. I dont work, im a disabled veteran, so i stay at home and watch my children, when they are in school that is my shop/play time.

Thanks for the comments, i will check the gallery and see if i can find your work!!

Richard

SO far im really enjoying the knife making processes and find using files much easier to get better results. The grinder takes more practice. I have a bunch of steel on the way and i will be using it to mainly practice doing bevels. Thats the hard part for me so far. Getting them profiled out is not as difficult. The smaller knife is ready to go to heat treat. Then i will add scales and finish cleaning it up and put on the edge.

I used a chainsaw file to add a sharpening notch choil on this one, worked great and only took a couple minutes, and that was going slow to make sure i kept it straight and even and where i wanted it.

As far as the swamp rat brotherhood and Beckerheads these are both groups for manufactured knives. Beckerheads are a group of fans for the Ka-Bar Beckers. And Swamp Rat is a company in the Busse family. The SR Brotherhood is a fairly new thing, we came up with a brotherhood knife on the SR Rat chat forum. There is not much to it, other than a group of us loyal fans that really enjoy the knives.

For becoming a Beckerhead there are different things you must accomplish in order to do so. You can check out the Becker subforum and get all the information if your interested, or let me know and i can send you an email.

Neither have to do with knife making though. Im newer to this than you if you been doing it a few months. I just started when i started this thread LOL. So i been in it for 10 days now. But im hooked. And will continue to practice and keep on making knives as time allows. Right now my kids are out of school today and tomorrow so i havent had a lot of time to play around. I dont work, im a disabled veteran, so i stay at home and watch my children, when they are in school that is my shop/play time.

Thanks for the comments, i will check the gallery and see if i can find your work!!

Richard

- Joined

- Sep 30, 2012

- Messages

- 15,381

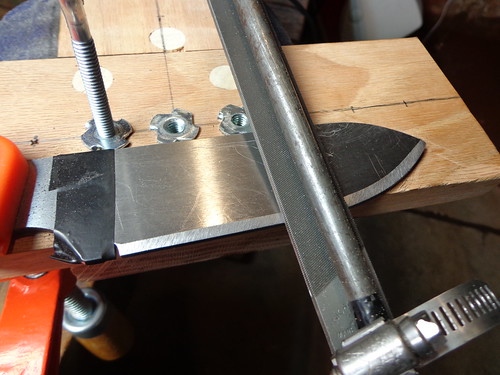

I should get a 12" double cut bastard file tomorrow, i ordered that specifically for the file jig. I have a 10" bastard file here but its single cut.

However im impatient, so i just spent around 10-15 minutes trying the jig out with the 10" file anyways LOL. I like it a lot so far. The double cut will remove steel quicker, and the extra 2" will make a lot of difference i think, not in the fact it will work quicker because its 2 extra inches, but because im only using the section of the file before the taper starts, so the extra 2" will give me more room on the file itself to use.

Did a little more and called it quits for the night.

However im impatient, so i just spent around 10-15 minutes trying the jig out with the 10" file anyways LOL. I like it a lot so far. The double cut will remove steel quicker, and the extra 2" will make a lot of difference i think, not in the fact it will work quicker because its 2 extra inches, but because im only using the section of the file before the taper starts, so the extra 2" will give me more room on the file itself to use.

Did a little more and called it quits for the night.

Last edited:

- Joined

- Jun 3, 2014

- Messages

- 31

they look good for a first attempt. my first attempt did not go so well.

- Joined

- Sep 6, 2014

- Messages

- 5,134

Neither did mine.lol

- Joined

- May 19, 2012

- Messages

- 2,913

nice grind WW, looking good

- Joined

- Apr 20, 2013

- Messages

- 7,205

Lookin' good, WW. You've got me inspired - I'm going to see about getting some steel next week.

- Joined

- Sep 30, 2012

- Messages

- 15,381

Lookin' good, WW. You've got me inspired - I'm going to see about getting some steel next week.

:thumbup: sounds good man, i look forward to seeing what you create!!

- Joined

- Sep 30, 2012

- Messages

- 15,381

Managed to get down in the basement for a few hours while everyone was asleep and make a mess of things.

Still a lot to go, this jig is nice but it takes FOREVER.

This was a pain in my A$$!!! I need to pick up a round file, thats bigger than a chainsaw file.

Still a lot to go, this jig is nice but it takes FOREVER.

This was a pain in my A$$!!! I need to pick up a round file, thats bigger than a chainsaw file.

- Joined

- Sep 30, 2012

- Messages

- 15,381

Thanks Zulu,

This shows how its made and at the end shows it in use. He says it takes 45 minutes to bevel each side... However its taking quite a bit longer for me honestly. I probably have 2.5 hours in that one side so far. And i still want to take the grind higher.

[video=youtube;r9iNDRwwBQQ]https://www.youtube.com/watch?v=r9iNDRwwBQQ[/video]

This shows how its made and at the end shows it in use. He says it takes 45 minutes to bevel each side... However its taking quite a bit longer for me honestly. I probably have 2.5 hours in that one side so far. And i still want to take the grind higher.

[video=youtube;r9iNDRwwBQQ]https://www.youtube.com/watch?v=r9iNDRwwBQQ[/video]

- Joined

- Jun 3, 2014

- Messages

- 31

Wow that is a lot of work, but looks incredible! I think the knives made by hand look wonderful.