Magnus Knives

Knifemaker / Craftsman / Service Provider

- Joined

- May 2, 2022

- Messages

- 23

This thread is where I'll be showing the designing, prototyping, testing, tweaking and (hopefully, at least) the producing of my first flipper knife.

Firstly, I have to get something off my chest...

I like framelock knives ...but I don't LOVE framelock knives.

Don't get me wrong. All my knives are titanium-scaled framelocks.

But it bothers me that I have to put my thumb across where the blade comes down -- together with having to change my hand position -- just to close the knife.

So here's my thinking...

If I'm going to make a flipper knife from scratch, then why not go to the very beginning and see if we can come up with a different locking (and therefor closing) mechanism.

I'm not going into this all starry-eyed and totally clueless (only a little starry-eyed ...and somewhat clueless ).

).

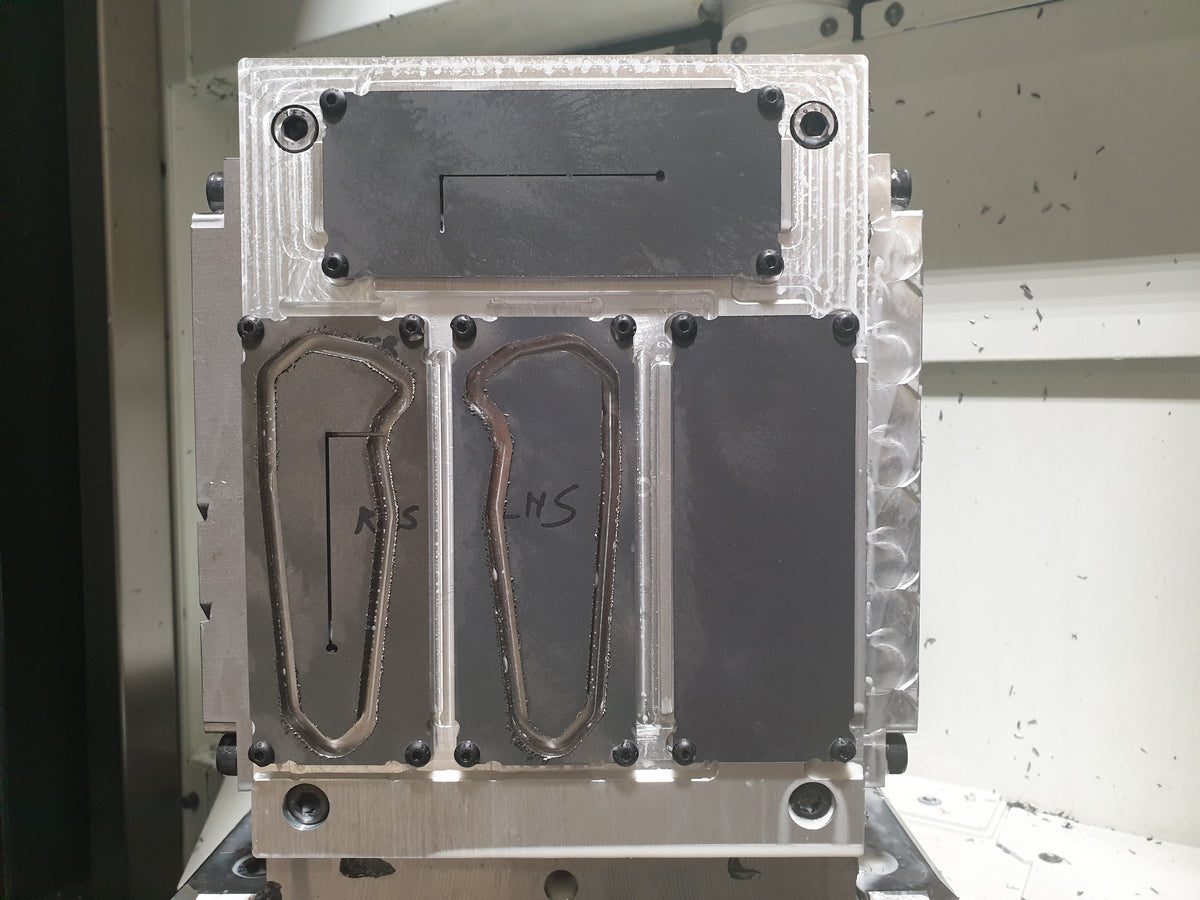

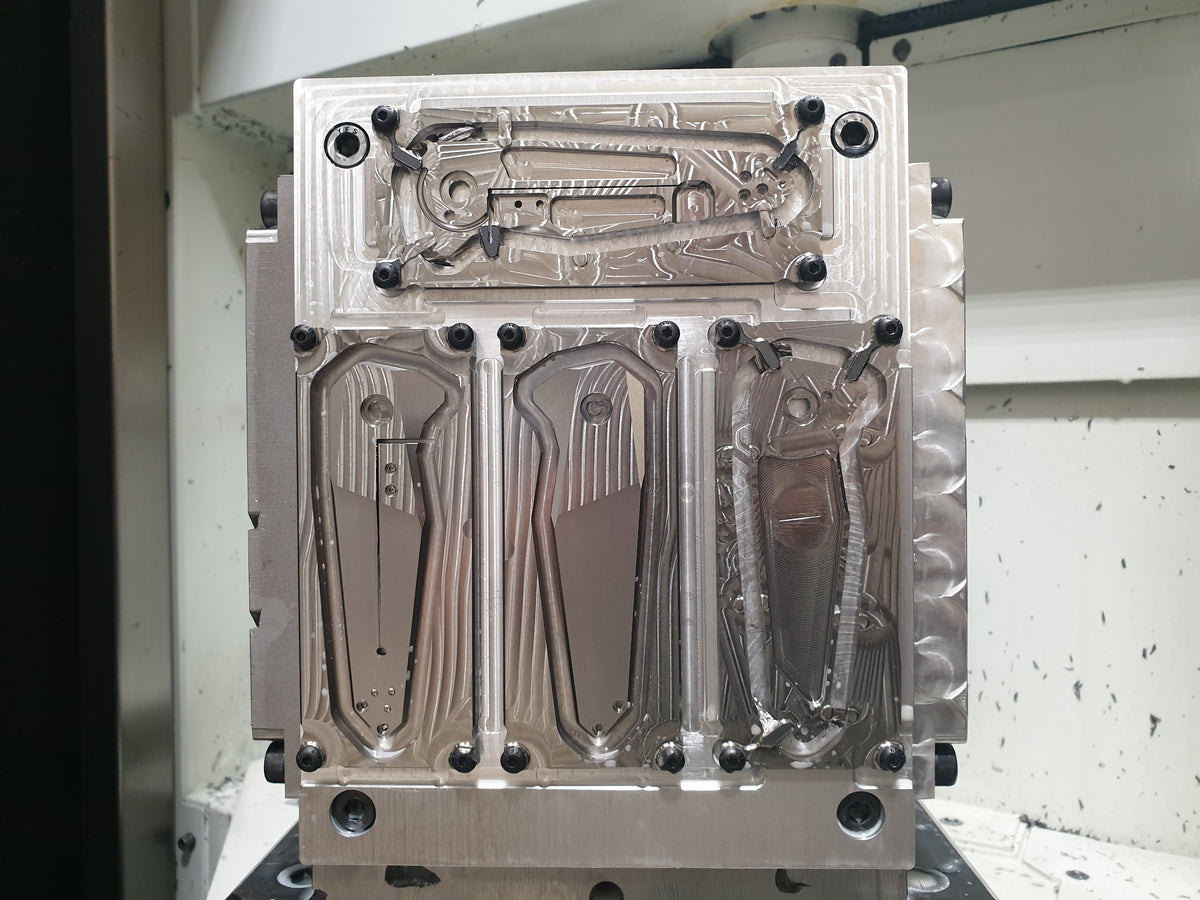

I've made a few flipper knife prototypes in the past. They got to the 95% finished stage and just needed some tweaks. All were framelocks.

Oh, and one more thing...

I'm a CNC guy. While I can only look on in awe at knifemakers who grind bevels on a knife grinder ...it's just not my style.

One of the hardest parts of the prototype knives I CNC-machined was getting the surface finish on the main bevels dialed-in. But, having spent a few hundred hours on it, I was starting to get somewhere when I put them on hold few years ago.

In terms of the locking mechanism...

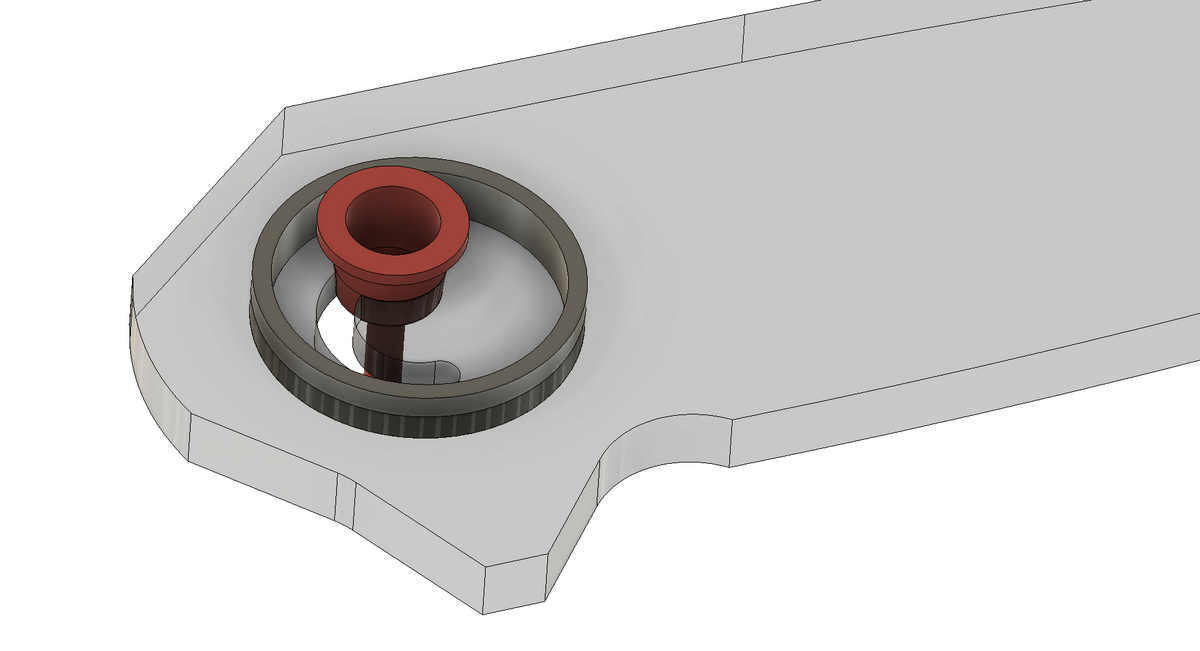

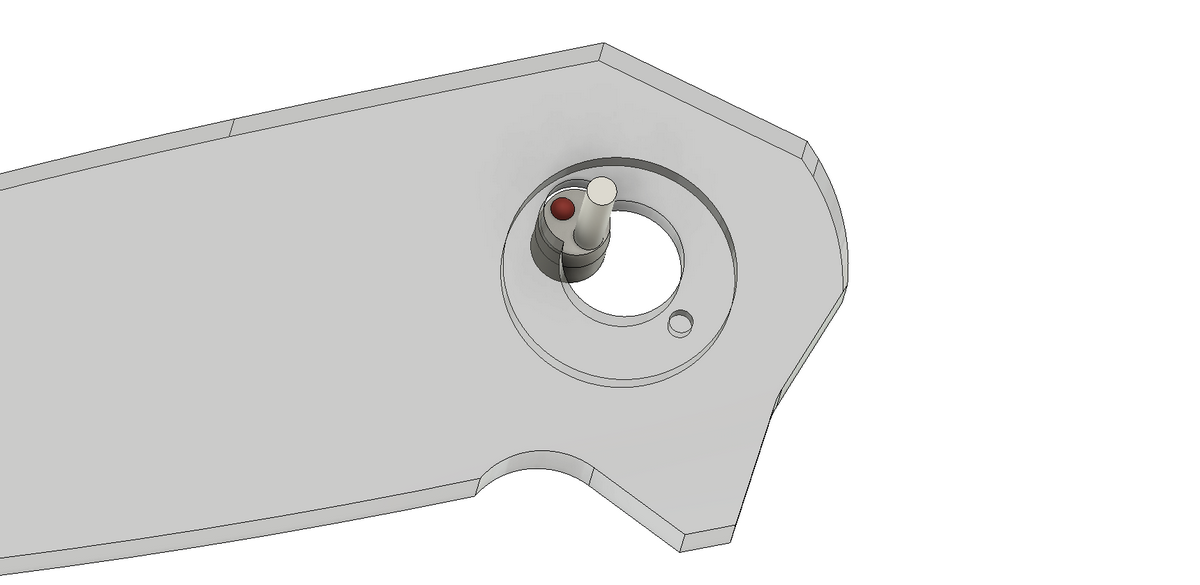

I've spent a lot (a LOT!) of time over the last couple of months designing various mechanisms. Most of the initial design concepts I do in my head ...and, if they show promise, I then go to CAD to flesh them out a little more and try and discover the various flaws (of which there is always at least one or two issues and is why, currently, I'm still at the R&D stage ).

).

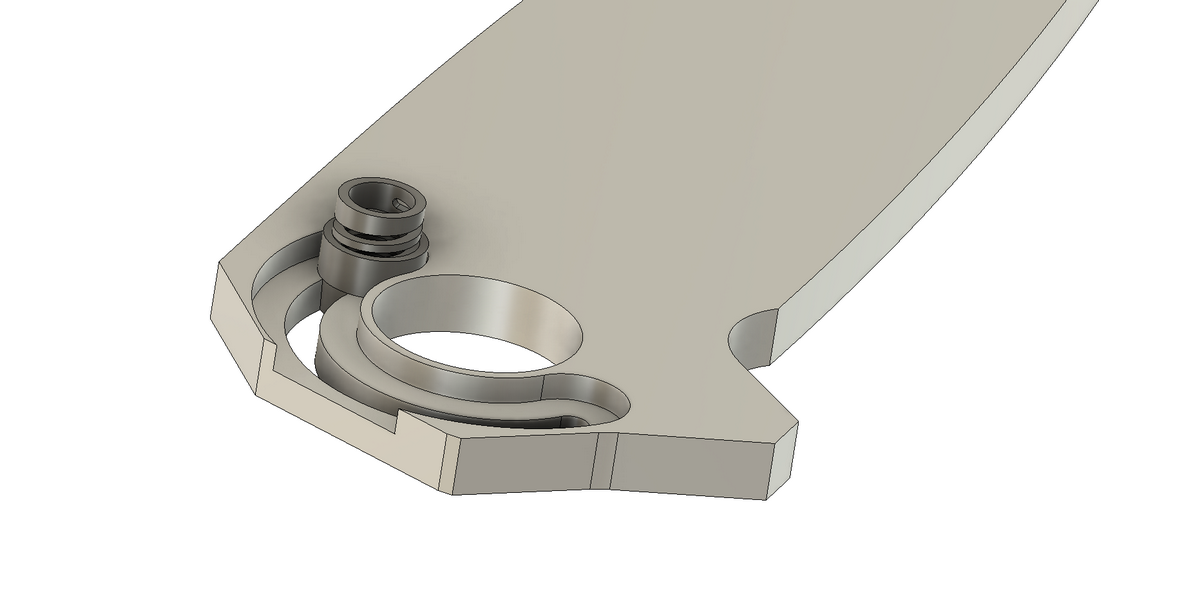

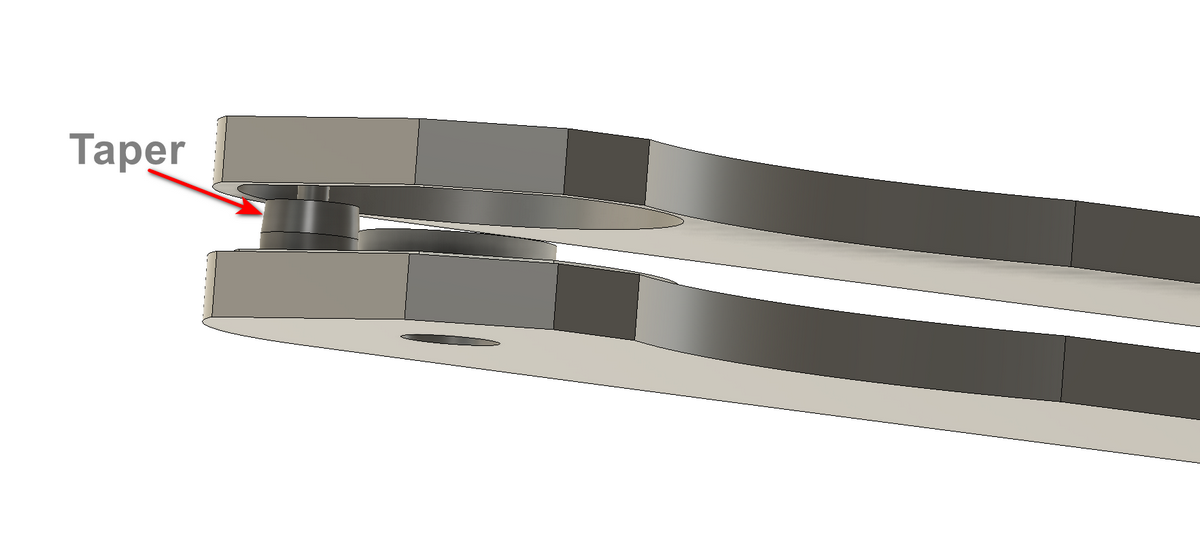

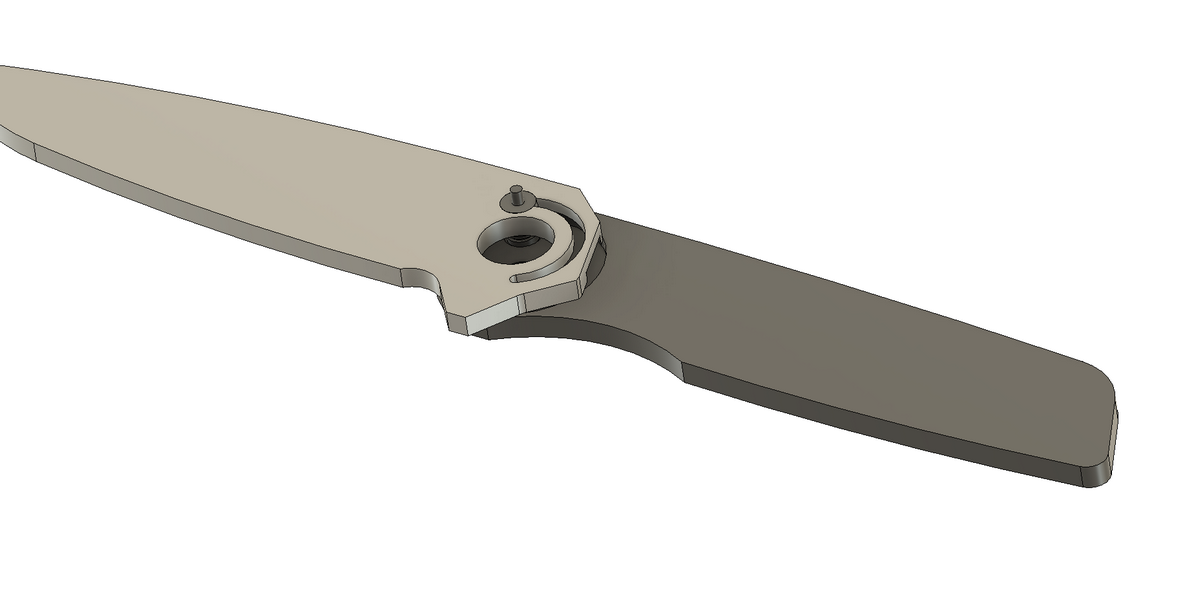

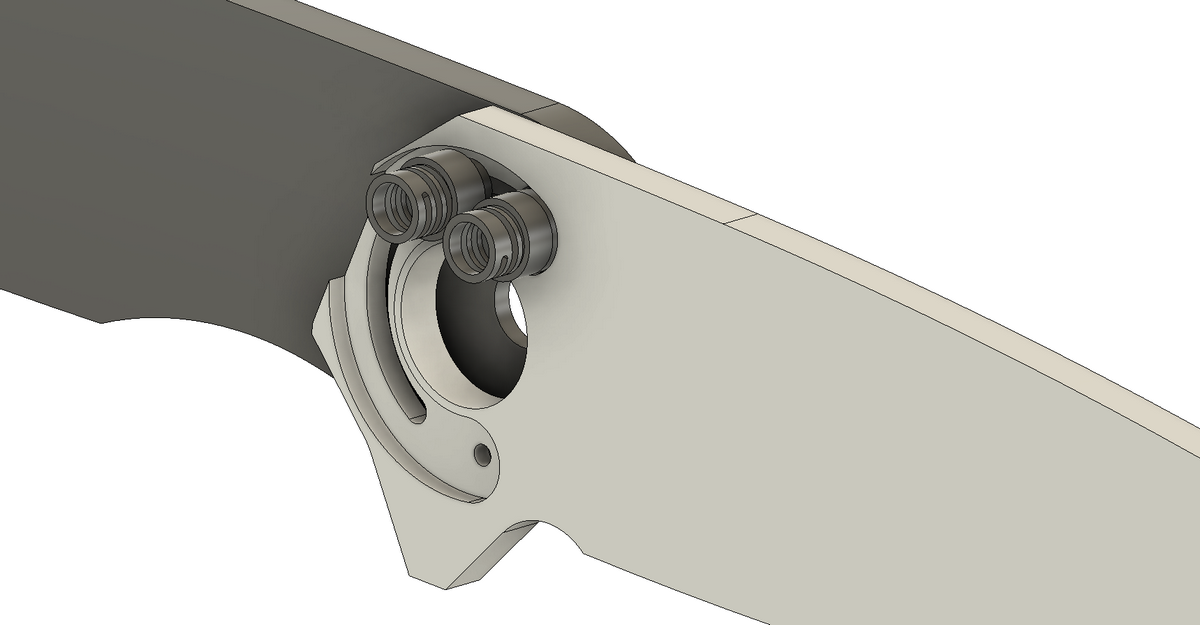

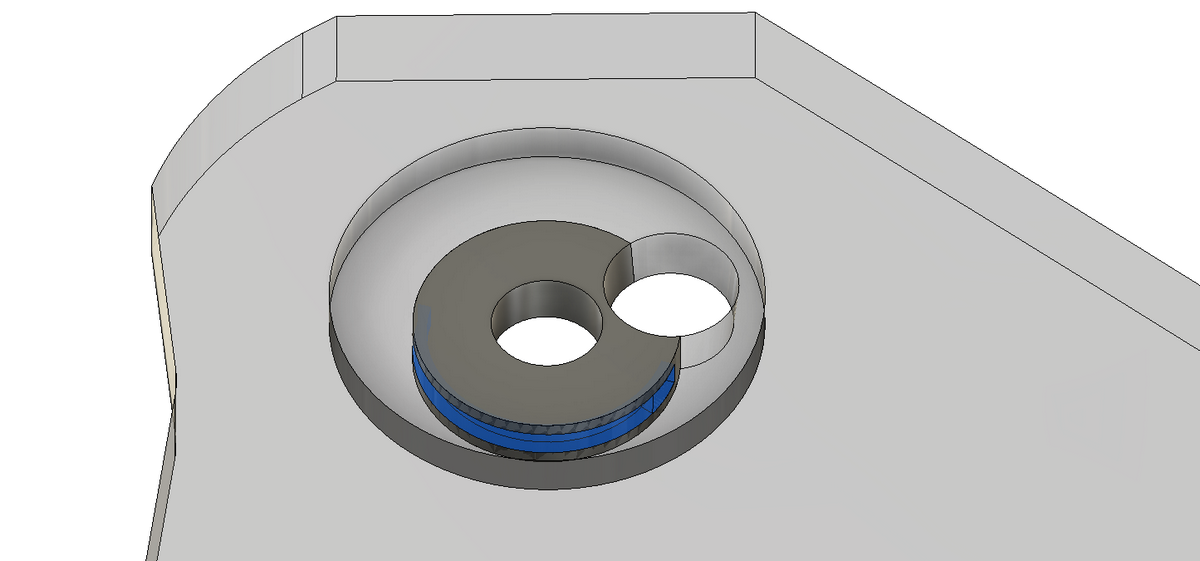

What I'll do is post where I currently am with the mechanism (various CAD screenshots).

One last thing...

Initially, I think this thread will likely have a bit of a slow-burn in terms of progress while we come up with locking mechanism.

But, once that's sorted, we should start to make decent progress with the knife overall.

Firstly, I have to get something off my chest...

I like framelock knives ...but I don't LOVE framelock knives.

Don't get me wrong. All my knives are titanium-scaled framelocks.

But it bothers me that I have to put my thumb across where the blade comes down -- together with having to change my hand position -- just to close the knife.

So here's my thinking...

If I'm going to make a flipper knife from scratch, then why not go to the very beginning and see if we can come up with a different locking (and therefor closing) mechanism.

I'm not going into this all starry-eyed and totally clueless (only a little starry-eyed ...and somewhat clueless

I've made a few flipper knife prototypes in the past. They got to the 95% finished stage and just needed some tweaks. All were framelocks.

Oh, and one more thing...

I'm a CNC guy. While I can only look on in awe at knifemakers who grind bevels on a knife grinder ...it's just not my style.

One of the hardest parts of the prototype knives I CNC-machined was getting the surface finish on the main bevels dialed-in. But, having spent a few hundred hours on it, I was starting to get somewhere when I put them on hold few years ago.

In terms of the locking mechanism...

I've spent a lot (a LOT!) of time over the last couple of months designing various mechanisms. Most of the initial design concepts I do in my head ...and, if they show promise, I then go to CAD to flesh them out a little more and try and discover the various flaws (of which there is always at least one or two issues and is why, currently, I'm still at the R&D stage

What I'll do is post where I currently am with the mechanism (various CAD screenshots).

One last thing...

Initially, I think this thread will likely have a bit of a slow-burn in terms of progress while we come up with locking mechanism.

But, once that's sorted, we should start to make decent progress with the knife overall.