- Joined

- Mar 5, 2021

- Messages

- 207

I am no bladesmith. Just trying to replace the Polypropylene handles on the Cold Steel 2 handed machete. Upon removal of handle I ended up more confused than ever. My questions are this. Keep in mind I am working with basic hand and power tools. And have construction (Not knife building) experience.

1. Would Micarta or G10 be good for this style of blade? Will it be shock resistant upon strikes into hard wood? If not. Could you recommend something aside Neoprene handles that would look nice and absorb shock?

2. How do I measure the holes in this in order to add brass pins or screw in nuts / bolts? Or is it even feasible? Is these 2 factory holes all I need or will they not be enough and cause separation of handle slabe?

3. How would I measure the holes diameter in order to find pins to fit it?

4.Is it possible to add any sort of guard to this purely for aesthetics?

5. Where can I find 10 inch long Micarta or G10 handle slabs? I looked in a few online stores and did not find anything.

6. Or would I be better off doing a handle wrap in place of adding Micarta or G10 scales as it may be too complicated for a novice. Or not possible to do with this handle or lack of specialty tools / knowledge?

Some specs of my machete.

Weight:

21.1oz

Blade Thickness:

2mm

Blade Length:

21in

Blade Steel:

1055 Carbon Steel with Black Baked-On Anti Rust Matte Finish

Handle Length/Material:

9in Long Polypropylene

Overall Length:

30in

Additional Features:

Cor-Ex® Sheath

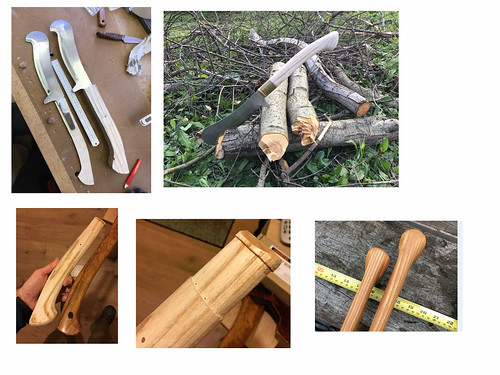

Here are a few pictures of the Polypropylene handle I removed. I want to make this simple as possible and yet have a halfway nice looking handle.

Any advice appreciated.

1. Would Micarta or G10 be good for this style of blade? Will it be shock resistant upon strikes into hard wood? If not. Could you recommend something aside Neoprene handles that would look nice and absorb shock?

2. How do I measure the holes in this in order to add brass pins or screw in nuts / bolts? Or is it even feasible? Is these 2 factory holes all I need or will they not be enough and cause separation of handle slabe?

3. How would I measure the holes diameter in order to find pins to fit it?

4.Is it possible to add any sort of guard to this purely for aesthetics?

5. Where can I find 10 inch long Micarta or G10 handle slabs? I looked in a few online stores and did not find anything.

6. Or would I be better off doing a handle wrap in place of adding Micarta or G10 scales as it may be too complicated for a novice. Or not possible to do with this handle or lack of specialty tools / knowledge?

Some specs of my machete.

Weight:

21.1oz

Blade Thickness:

2mm

Blade Length:

21in

Blade Steel:

1055 Carbon Steel with Black Baked-On Anti Rust Matte Finish

Handle Length/Material:

9in Long Polypropylene

Overall Length:

30in

Additional Features:

Cor-Ex® Sheath

Here are a few pictures of the Polypropylene handle I removed. I want to make this simple as possible and yet have a halfway nice looking handle.

Any advice appreciated.

Last edited:

Billhook comp

Billhook comp Frame Tang

Frame Tang