Put me down for a work rest, ceramic liner, platen, small wheel attachment and both arms.I am currently out of stock on work rests but should have more by the end of next week. Everything else I have on hand.

I’ve modified the platen brackets to allow for more backwards adjustment and also I just got in a shipment of ceramic platen liners to fit these grinders.

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grizzly 2x42 Upgrades!

- Thread starter Contender Machine

- Start date

Contender Machine

Dealer / Materials Provider

- Joined

- Jun 23, 2015

- Messages

- 355

Will do! If you could, please email me a shipping address.Put me down for a work rest, ceramic liner, platen, small wheel attachment and both arms.

Darren@contenderworks.com

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,409

Welcome jarhead77.

Fill out your profile so we know a bit about you and where you live.

You are new and probably did not read any of the website rules, but buying and selling are not allowed in any place buy The Exchange. The following note is a reminder to all the others about this rule.

PLEASE - do not do sales, buying selling, ordering, etc. in Shop Talk.

Go to their website, email, or PM.

Fill out your profile so we know a bit about you and where you live.

You are new and probably did not read any of the website rules, but buying and selling are not allowed in any place buy The Exchange. The following note is a reminder to all the others about this rule.

PLEASE - do not do sales, buying selling, ordering, etc. in Shop Talk.

Go to their website, email, or PM.

Contender Machine

Dealer / Materials Provider

- Joined

- Jun 23, 2015

- Messages

- 355

Dang he went all out! Pretty cool thanks for sharing.

I watched the episode where he cast that dovetail axe. Quite cool stuff.More ideas for upgrades...

bladegrinder

Knifemaker / Craftsman / Service Provider

- Joined

- May 4, 2013

- Messages

- 599

I have a 1 x 42 belt sander that I've used for handle shaping for years and it's on it's way out. looking for a new one, with variable speed this popped up, question is though, will this track 1" belts ok or do you have to use 2" belts? anyone tried 1" belts on this machine?

I'm impressed that Grizzly not only sells spare parts for these but the parts are cheap. I ordered extra stuff so I can quickly change the tool arm and have glass platen, radius platen, or slack belt in and running in seconds. I got 4 wheels, 4 spindles, & 2 C brackets for $70 delivered.

- Joined

- Apr 9, 2013

- Messages

- 26

Just ordered my today, and although I've only made 2 knives (unknown steel from one of my my grandfather's old 1950's stone chisels), I won't be able to not pimp it out with some custom attachments. I do abuse my current HF 1x30 belt grinder for fabrication and repair of farm stuff, so the Grizz will have other uses. The little HF grinder is still ticking after 6 or so years, but it sucks for large stock.

- Joined

- Mar 1, 2025

- Messages

- 1

Are you selling the platen and work table? If so I'd be interested in purchasing them.Well like many other knife makers on here when I saw the new Grizzly 2x42 belt grinder on the market I bought one immediately. The price of this thing is just crazy cheap. It’s easily the best grinder you can get for under $400 because well it‘s about the only grinder you can get for under $400. That being said it is cheap for a reason. The build quality and design is not the best as can be expected.

So naturally I did some upgrades! Since I make a living building grinders and grinder accessories I do intend to build and sell these upgrades to anyone who would like them but I thought I’d just start by sharing what I have done so far. I’d love to here any comments or ideas for further upgrades.

First thing I did was make new platen brackets as well as a simple steel platen. I made the brackets slotted so that it has adjustment both left to right (to center the platen up to the belt better) as well as adjustment in and out to allow for running radius platens. I haven’t made any radius platens yet though. Would anyone be interested in radius platens for this grinder?

Here‘s the new platen and brackets mounted in the stock platen frame. The new brackets allow better access to both sides of the platen.

The next thing I did was make a couple of new work rests. I made a 5x12 inch work rest that can tilt both forward and back 15 degrees. This along with tilting the platen itself allows for a wide range of angles. I also made a drop down work rest arm to allow for better jig grinding as it gives you access to more of the platen. By nature of the design you can only tilt back 15 degrees with the drop down arm. Tilting forward is limited because the work rest hits the arm.

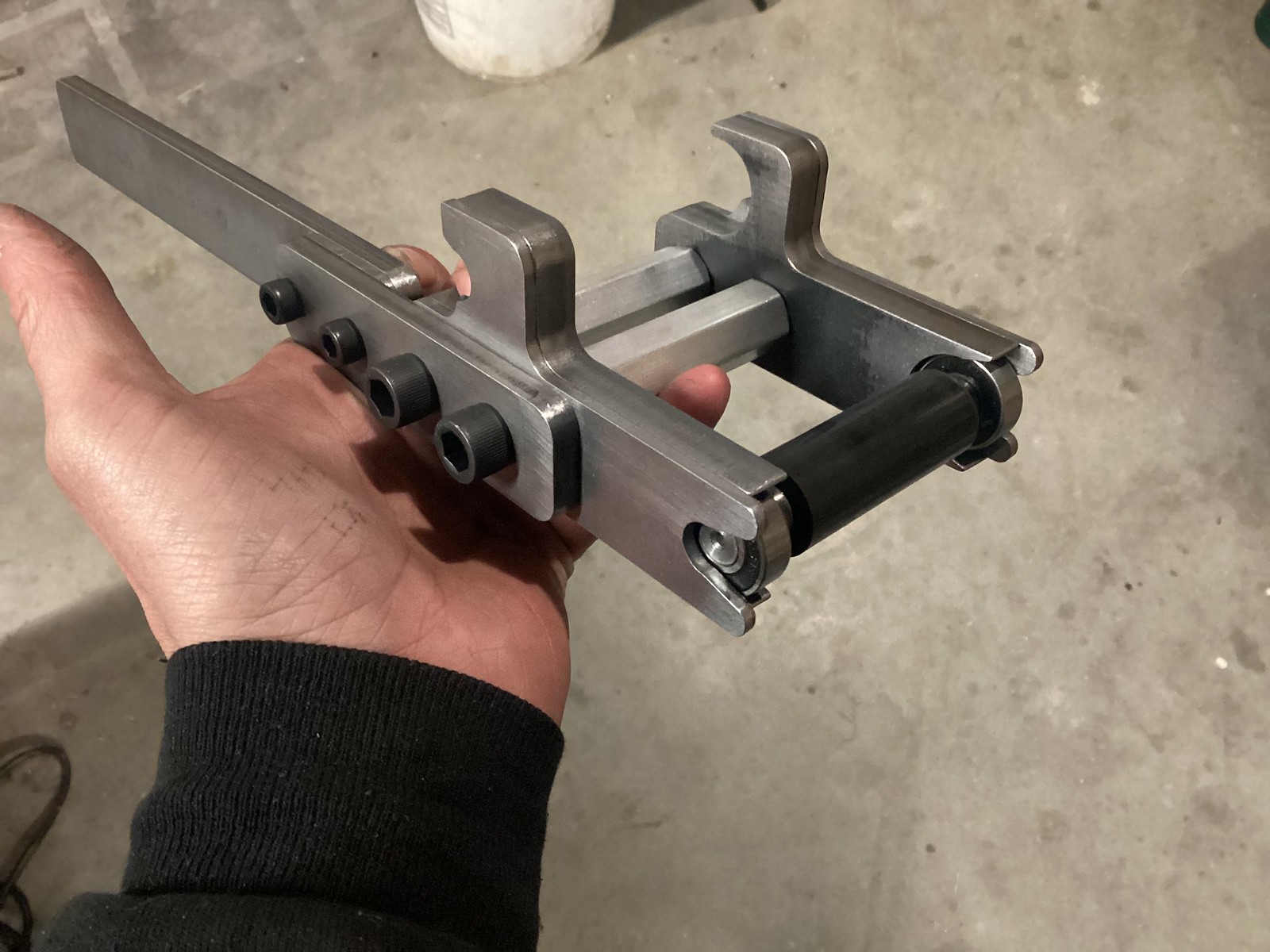

The last and probably most exciting thing I made was a small wheel attachment. This prototype is made to fit the standard small wheels that use 7/8 OD bearings with an overall length of about 3 1/8 inches. A lot of knife makers already have these wheels to use with there 2x72 so making the attachment use these wheels was the most practical. It accepts up to 2 wheels so that one acts to flatten the belt out.

This works really well.

Since this is a very cheap grinder to start with I had to design these attachments to be cheap and quick to make. It’s mostly just laser cut steel with some drilled and tapped holes and some milled slots. They went together very nicely and seem to run very well.

I intend to have both some flat and radius platens heat treated to make them hold up a lot better to the heat and belt wear.

Let me know what you guys think and if any of you would be interested in adding these upgrades to your new grinder as well! As always I’m open to suggestions!

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,409

Welcome stolen pillow. Fill out your profile so we know where you live and a bit about you.

Please contact Contender on their website or by Direct Message for buying information. Buying/selling is not allowed in Shop Talk.

www.contenderworks.com

www.contenderworks.com

Please contact Contender on their website or by Direct Message for buying information. Buying/selling is not allowed in Shop Talk.

Contender Machine Works

- Joined

- May 3, 2022

- Messages

- 122

Ha! More like $700!I sold wanted to grab one of these little machines and all these upgrades. However, it's now almost $500 with tax. Not sure it's worth it???

The Contender Mods are worth the coin.

If only Grizzly could come up with a better tracking adjustment.

Overall, I am happy with it and the mods.

Just don’t push it too hard!

- Joined

- Jun 8, 2023

- Messages

- 128

I bought the first Gen that came out back when they were at like 380 I think. If $700 is the number now, that's insane. I def don't think this things worth over 500 unless it's been upgraded a lot. Don't get me wrong, I've used mine a bunch and upgraded it significantly. Every time I see a picture of one posted I'm like "what is that weird little thing" then I realize that's what mine looked like for a couple weeks. You could buy select parts from housemade make the rest and buy a decent motor and drive for under 1000. And that's a real 2x72. And if you're not into making stuff I'd probably look at vevor or similar and upgrade from that platform. No matter what in this price range you're gonna be doing some tinkering to get it to act right and be dependable.

Edit- just looked it up. 480$ is reasonable. I'm guessing you were meaning with all contender upgrades brings it to 700. Go ahead and add 250 to that for a reversible higher power servo motor from servomotorkit or Amazon as well once that motor keels over.

Edit- just looked it up. 480$ is reasonable. I'm guessing you were meaning with all contender upgrades brings it to 700. Go ahead and add 250 to that for a reversible higher power servo motor from servomotorkit or Amazon as well once that motor keels over.