You're yelling!

I have read that thread, and it seems to focus on the depth of the blade in the clamp. That's not in play here.

Sorry your self-evident expertise is just not making sense to me, nor is it showing up in my use of the KME.

Oh well, onward and upward.

I am not aware that I am yelling nor is that my intention, I just want to help.

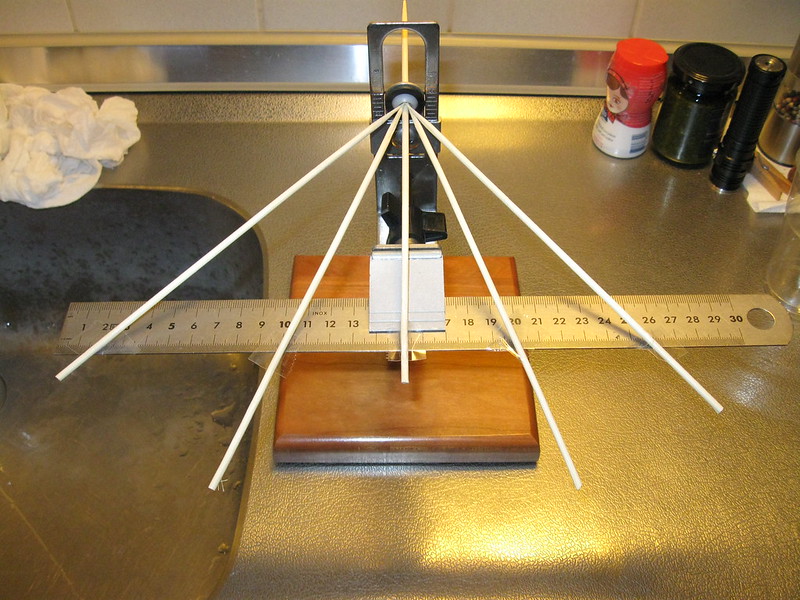

Here are two photos I just made. One front view and one side view that hopefully make more sense to you.

Both show the same as cbwx34 showed in the other thread:

When I first saw the Wicked Edge post a few years back, that the angle doesn't change, I thought, "that's crazy, of course it changes". It's basic trig that most learn... if the distance increases, the angle decreases in a triangle, right?

Long story short, after a bunch of testing, I ended up figuring out, that WE is right. As long as you're in the straight area of the blade, the angle won't change, no matter how far down you go. Take a look at these pictures...

I figured the easiest way to prove WE wrong, was to take an extreme example. So, if you look in the top photo, I took a flat piece of aluminum and mounted it in the WE. Then I took dental floss and from the same point on the angle bar (20 deg I believe, it's been a few years), I attached it to points on the aluminum. If you look at the top photo, it seems obvious that the angle is getting smaller as you go down the "blade" right? But, if you put a stone on the arm, and held it as far out as you could, the relation between the aluminum and the stone didn't change... it still contacted the aluminum at the same angle.

That's when I realized that the angles you see in the top photo are not the angle that the stone is sharpening at. If you take a look at the lower photo... a picture taken sighting down the aluminum, you can see that all the pieces of dental floss line up perfectly. This is the angle the aluminum "sees", and what the stone sharpens at.

To answer the question about the Lansky directions, I think that no-one ever really looked at this before. It just seemed logical that the angle would change, as you move away from the pivot.

I also think that there is some observances that sharpeners mistake for the angle changing. One is, as a knife curve towards the tip, if it's far away from the pivot, the angle can change... this is shown in the WE post. So the assumption is made that it was probably changing the entire length. Another factor... many knives taper as the move toward the tip, even in the straight area you sometimes move into thicker metal, which can result in a wider bevel. So, the assumption is made that the angle changed, even though it's actually a change in the blade. Finally, many blades aren't straight, but have a slight curve, which can change the angle.

The easiest way to test this is to set aside what you think you know is true, like I did, get a long straight knife or even a piece of metal... rig up something that looks like a Lansky or WE, and test it out. When you figure this out, you'll realize that the best way to "set" a knife on a guided sharpener (Wicked Edge, Edge Pro, Lansky, etc.), is not by the length, but by the relationship of the curved area toward the tip. Makes sharpening a lot easier.

Hope this helps!