- Joined

- Jan 10, 2015

- Messages

- 1,134

lucas, the easy answer is for you to get a copy of the US Forest service manual "An Ax To Grind" and watch the "An Ax To Grind" video. Sorry, I dont have the computer skills to link you to these.

The BladeForums.com 2024 Traditional Knife is ready to order! See this thread for details:

https://www.bladeforums.com/threads/bladeforums-2024-traditional-knife.2003187/

Price is $300 $250 ea (shipped within CONUS). If you live outside the US, I will contact you after your order for extra shipping charges.

Order here: https://www.bladeforums.com/help/2024-traditional/ - Order as many as you like, we have plenty.

lucas, the easy answer is for you to get a copy of the US Forest service manual "An Ax To Grind" and watch the "An Ax To Grind" video. Sorry, I dont have the computer skills to link you to these.

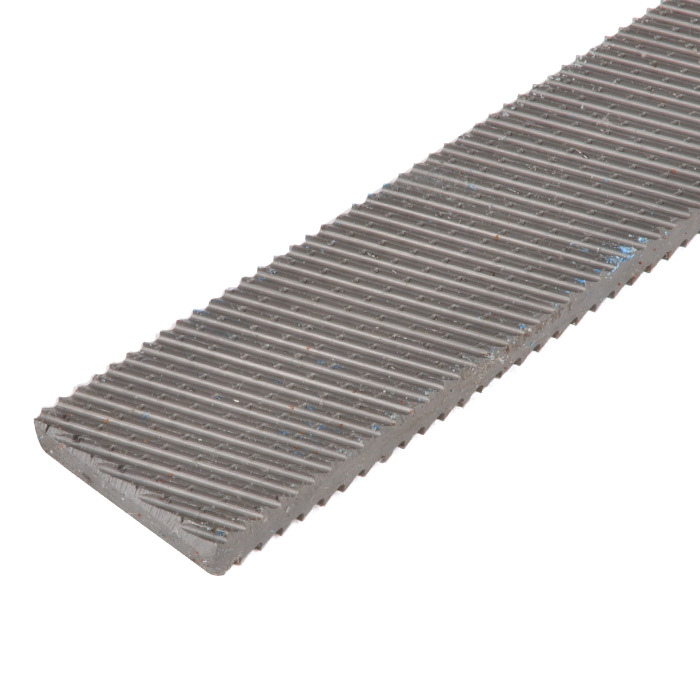

I never prescribed to putting in the time to make a bit edge to a mirror or an awesome shine, because as soon as I put it in the wood and use it for an amount of time its gone anyway. That's more cosmetic than anything. Loggers that used an axe 8-12-14 hours a day had a wet grind wheel, file, stone, and maybe some sand paper. That was enough then, and we don't need to reinvent the wheel now.

Oh, and never use a grinder, ever. Just my opinion.

idaho_crosscut---I spent a good part of my life working with an axe everyday for 2-3 months without returning to a location where electric power was available. And yes I know well about the mules stomping and blowdown. That is EXACTLY the stiuation where file and stone skills are crucial.

as far as the mirror edge goes, it really, really does make a difference. once you remove the majority of the 'large' micro serrations you reduce the amount your bit is wanting to "tear" and get dull. For example, that axe above can chop all day and still shave at the end of the day with only being stropped with my leather belt with a little compound on it. This was a revelation to me, because i used to think it was largely cosmetic as well.

Kelly Dandenong by https://www.flickr.com/photos/30283858@N07/

Kelly Dandenong by https://www.flickr.com/photos/30283858@N07/as far as the mirror edge goes, it really, really does make a difference. once you remove the majority of the 'large' micro serrations you reduce the amount your bit is wanting to "tear" and get dull. For example, that axe above can chop all day and still shave at the end of the day with only being stropped with my leather belt with a little compound on it. This was a revelation to me, because i used to think it was largely cosmetic as well. you have to think that a logger being paid stumpage would take every opportunity available to them to increase the "up time" on their axe, because if it wasnt dumping chips, they weren't making money, and seeing how modern loggers treat their chainsaws and their chains, i can't imagine that many were chopping trees with a rough "puck ground" edge. the technology to get an actually sharp edge has been around for a long, long time now. hell, some of the best sharpening stones ever quarried were during the "good old days" and many of which have been lost or used up.

as far as the folks mentioning that shape is more important, that is very, very much the case. you can get a 90 degree angle to shave hair, but you cant chop with it. sharpening an axe takes 10 seconds. profiling it takes hours upon hours of filing or grinding.

for folks who arent staunch traditionalists, there is no need to be afraid of a little 120v-- a little common sense is all you need. with great power comes great responsibility, yada yada.

yeah, and when you are in those situations, you bring a stone and a file, which i do. the last time i tried to plug in my grinder out in the woods, the mule nearly kicked my head off. turns out thats not an 'outlet' under the tail! everybody should know how to use a stone and a file to get an axe into fighting shape BEFORE they try and use a grinder. those skills are essential, no doubt. but i will say one last thing about the grinders... they do a damn, damn good job. there is a reason most competitive axemen have utilized this technology for quite a while now-- it isnt just an internet forum board opinion for them, the results speak for themselves during practice and competition.

.... vs all the things that goes into a mirror edge......