Alex T.

Beginner knifemaker

- Joined

- Mar 10, 2019

- Messages

- 119

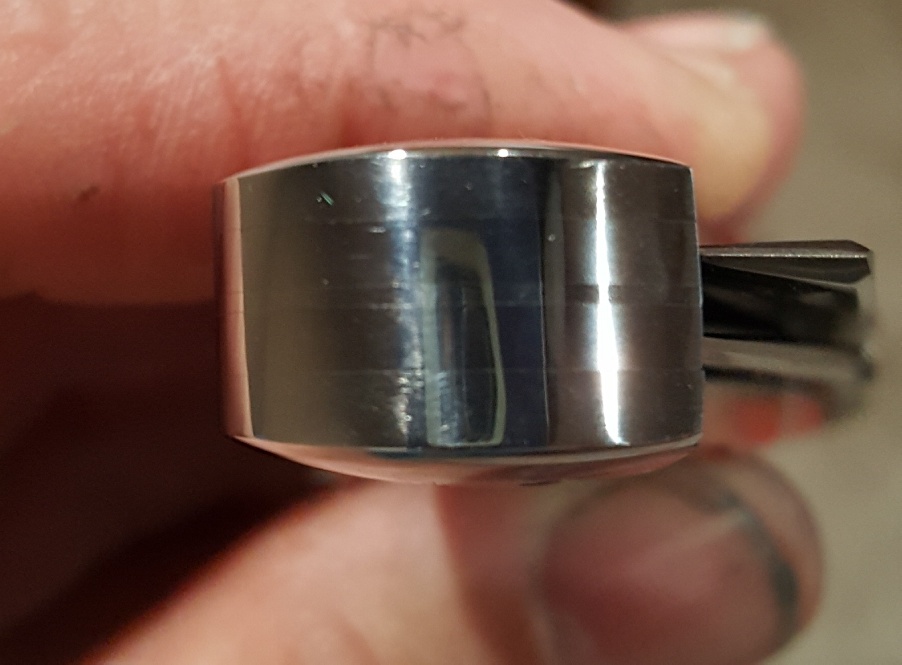

Basically the title, how can I get this seamless fit? Ultra flat surface? Method of fitting the bolster? Special grinding technique? Not put epoxy?

I want to hone my skills and I am seriously getting literally crazy. I spent literally 20 hours last week lapping a handle and bolster utntil they were very flat when tested on my granite plate + dykem. Also tested on new 123 blocks surface is flat, it seemed seamless. Then I pin everything, making sure bolster are flat on the tang, still no gap. Then I grind and it seem the finer I go the clearer the "gap" is visible (even tough you can't feel it with a finger). I am so obsessed by this problem it is getting ungesund (malsain in french?) Any tip? Is the epoxy overheating and expanding in the space?

I want to hone my skills and I am seriously getting literally crazy. I spent literally 20 hours last week lapping a handle and bolster utntil they were very flat when tested on my granite plate + dykem. Also tested on new 123 blocks surface is flat, it seemed seamless. Then I pin everything, making sure bolster are flat on the tang, still no gap. Then I grind and it seem the finer I go the clearer the "gap" is visible (even tough you can't feel it with a finger). I am so obsessed by this problem it is getting ungesund (malsain in french?) Any tip? Is the epoxy overheating and expanding in the space?