- Joined

- Feb 14, 2014

- Messages

- 20

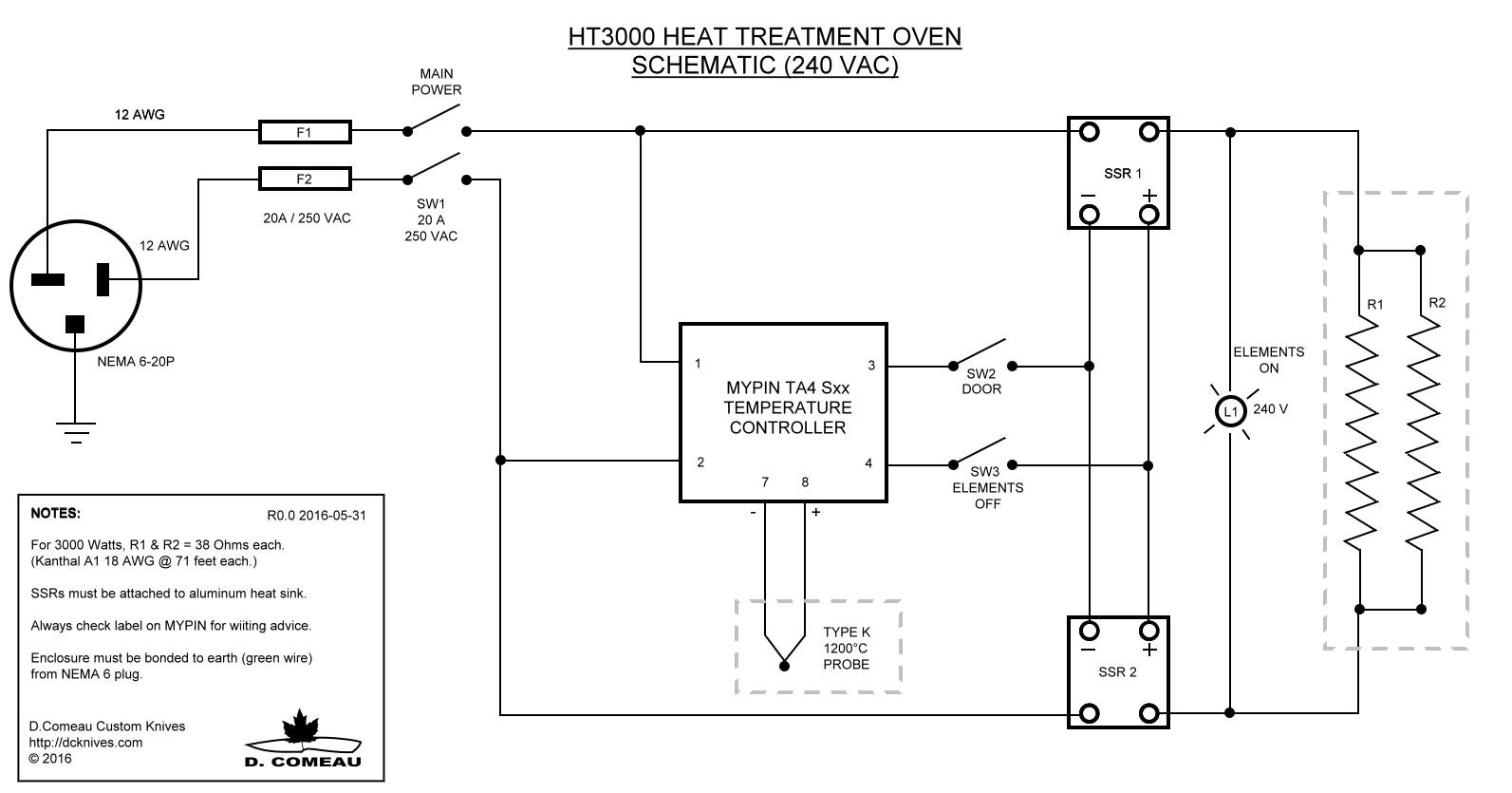

Greetings All! I have been trolling around the site for several years and found many many answers to everything I have worked on and had an issue with but I’m running into quite the brick wall on something this time. I am building a smallish HT oven and am at the point where I am building the control box but can’t find a simple wiring diagram for my application. I am trying to keep it uncomplicated. Here are the specs:

Yeah, I know... “not another oven dummy...”

SYL-2352P PID

40A SSR

Heat Sink

K Type Thermocouple

16 ga Kanthal A1

I will be winding my own element coil and have a good grip on all that as far as coil spacing and the math. Shooting for around 1300-1500 watts. The chamber is 4” wide, 4.5” tall, and 11” deep. I will be running the oven on 120vac because I don’t have 240vac set up in my work area yet. It’s coming but will be a while yet. I am not putting a door switch on it and no indicator lights. My plan is for the PID controller lights when powered up will indicate the oven is on, a power switch, and that’s it. When I want to go in the oven and open the door, I’ll shut the controller off with the mains switch. Trying to keep it simple. I’ll build a 240vac larger oven with other bells and whistles sometime in the near future and have found plenty of schematics for that type of a build but nothing for what I’m trying to build.

I have a grip on the basics of wiring the PID and associated stuff needed but want to find a good proven schematic to validate what I think needs to be done to wire it up safely and effectively. It should also be noted that I understand electrical wiring for both AC and DC circuits. Not a complete newbie here.

Hopefully someone will have a schematic or link that will help. I’ve looked high and low and scoured this site as well as others and have had no luck.

Thanks in advance for any help.

V/R

Steve.

Yeah, I know... “not another oven dummy...”

SYL-2352P PID

40A SSR

Heat Sink

K Type Thermocouple

16 ga Kanthal A1

I will be winding my own element coil and have a good grip on all that as far as coil spacing and the math. Shooting for around 1300-1500 watts. The chamber is 4” wide, 4.5” tall, and 11” deep. I will be running the oven on 120vac because I don’t have 240vac set up in my work area yet. It’s coming but will be a while yet. I am not putting a door switch on it and no indicator lights. My plan is for the PID controller lights when powered up will indicate the oven is on, a power switch, and that’s it. When I want to go in the oven and open the door, I’ll shut the controller off with the mains switch. Trying to keep it simple. I’ll build a 240vac larger oven with other bells and whistles sometime in the near future and have found plenty of schematics for that type of a build but nothing for what I’m trying to build.

I have a grip on the basics of wiring the PID and associated stuff needed but want to find a good proven schematic to validate what I think needs to be done to wire it up safely and effectively. It should also be noted that I understand electrical wiring for both AC and DC circuits. Not a complete newbie here.

Hopefully someone will have a schematic or link that will help. I’ve looked high and low and scoured this site as well as others and have had no luck.

Thanks in advance for any help.

V/R

Steve.