- Joined

- Jun 30, 2003

- Messages

- 1,797

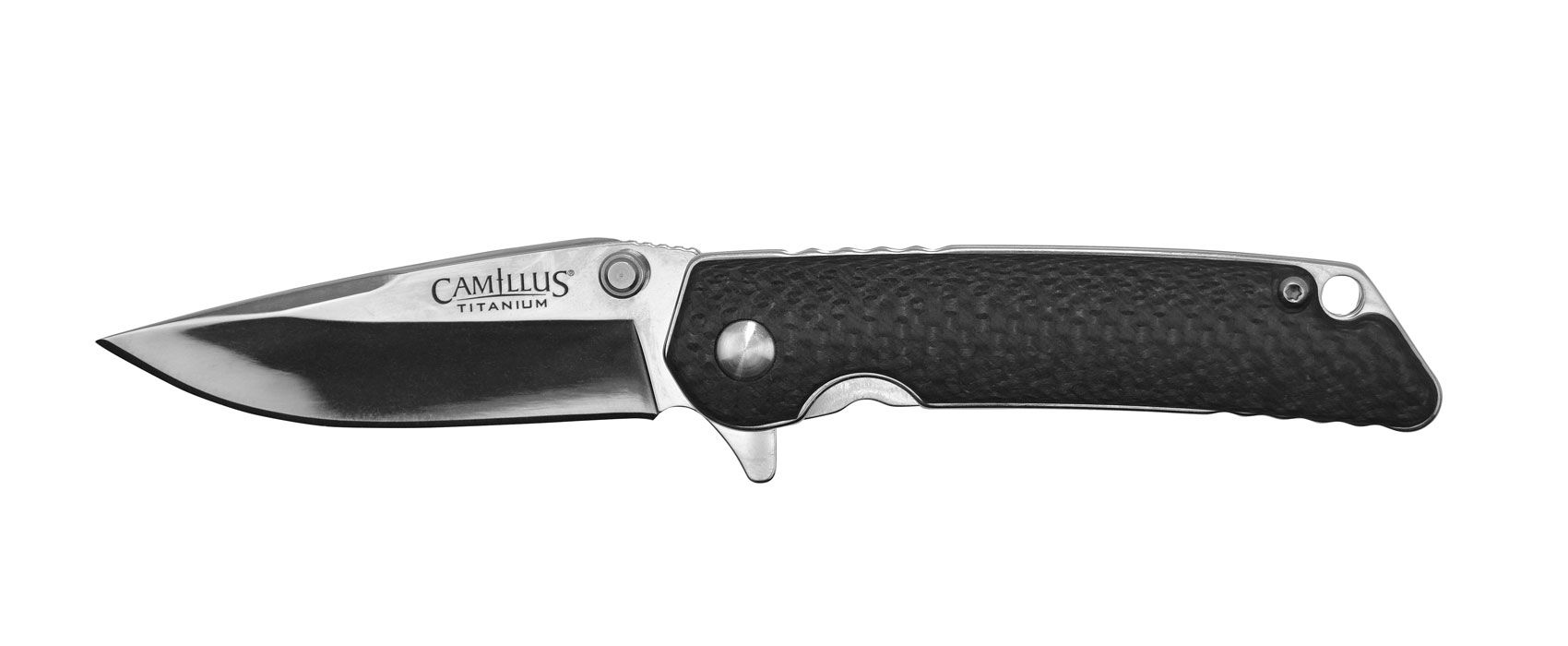

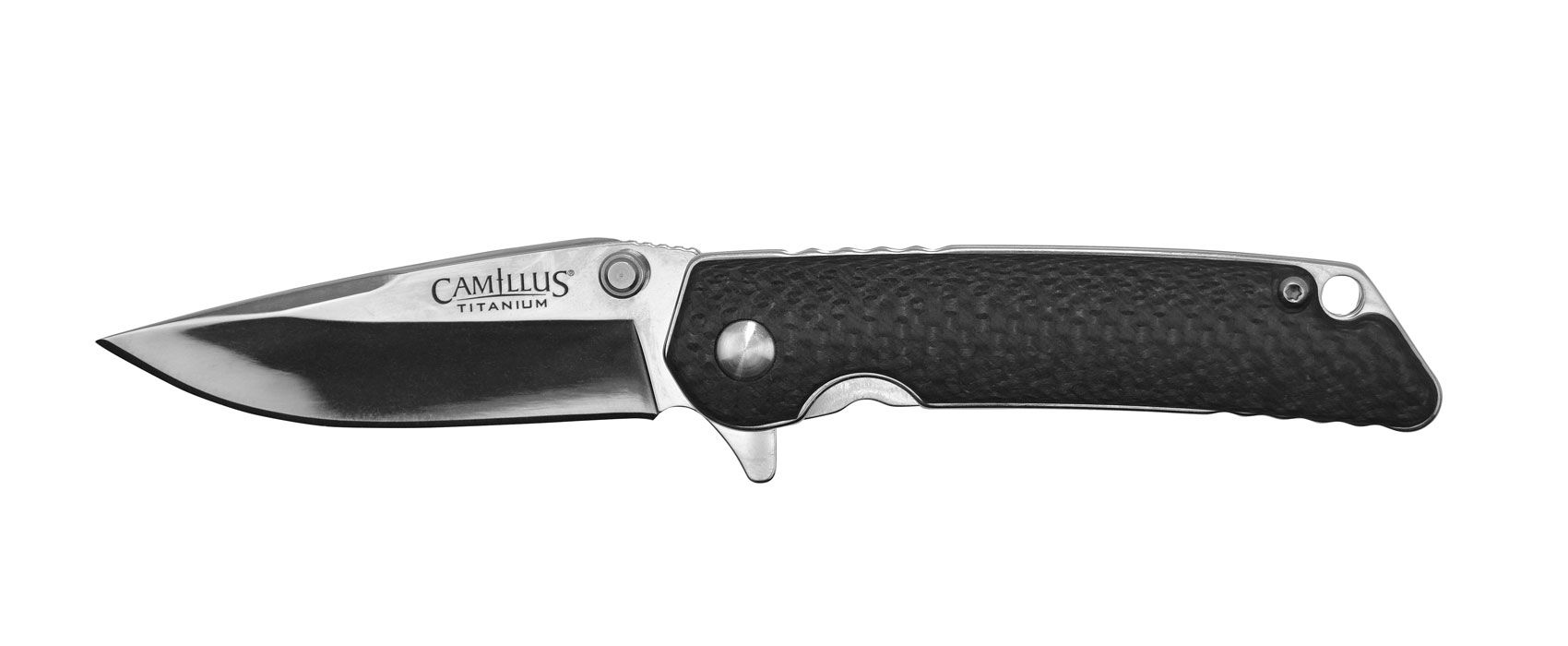

I just took a look over at Camillus' website, and one of the things that was on their main slideshow was this TRC 6.75" Folding Knife:

Titanium bonded just means that it has a coating of Ti on top of the substrate steel, in this case, VG-10, right?

Further down the page, they advertise a Rockwell hardness of RC65. I guess that is the hardness of the Ti coating. That of course wouldn't help the cutting edge, but would allow them to (somewhat deviously) advertise that it's harder even than a decent steel substrate. (The Rockwell hardness test is usually done on a flat area of steel, not an edge.) The blade is also hollow-ground, which I like.

Titanium bonded just means that it has a coating of Ti on top of the substrate steel, in this case, VG-10, right?

Further down the page, they advertise a Rockwell hardness of RC65. I guess that is the hardness of the Ti coating. That of course wouldn't help the cutting edge, but would allow them to (somewhat deviously) advertise that it's harder even than a decent steel substrate. (The Rockwell hardness test is usually done on a flat area of steel, not an edge.) The blade is also hollow-ground, which I like.