traumkommode

Gold Member

- Joined

- Dec 3, 2015

- Messages

- 4,471

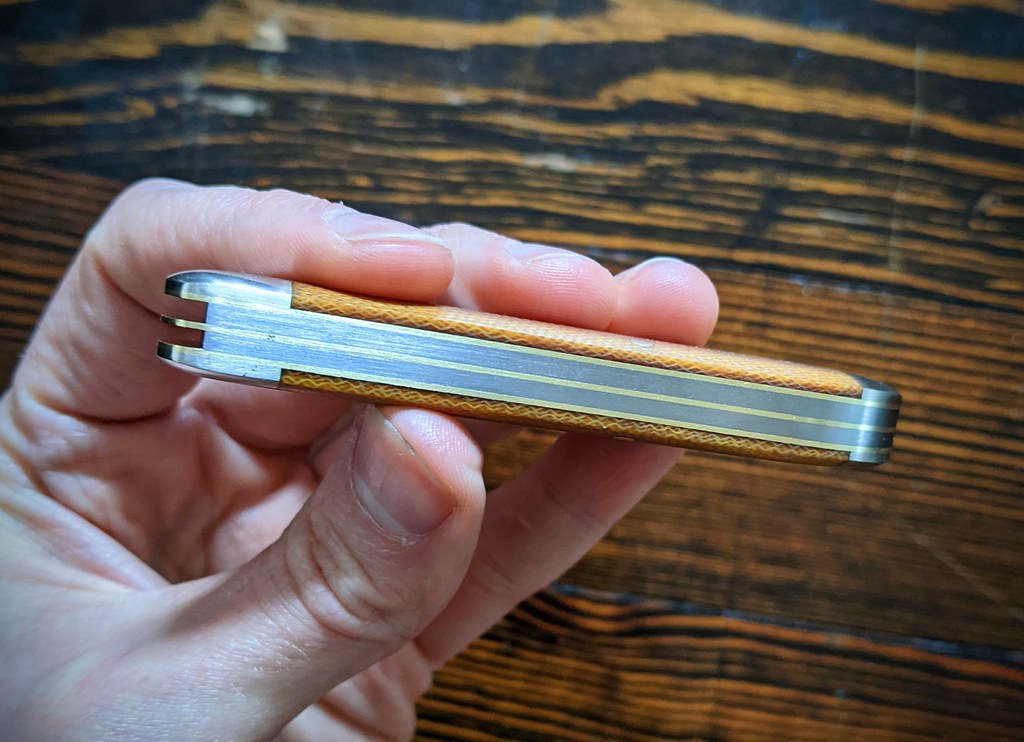

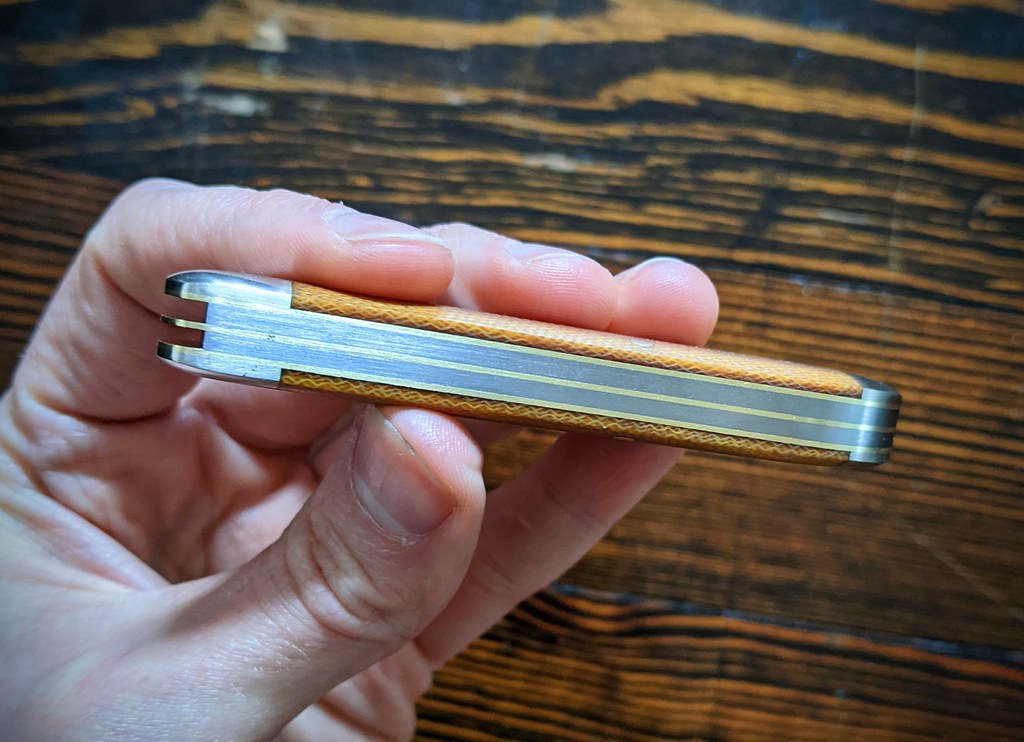

This week, I received this Natural Canvas Micarta #85 Crownlifter, about which I was very excited. I really liked my dead skunk acrylic, and really wanted a micarta, and when I saw this one and that perfect butteryscotch gradient on these covers, I had to pay the secondary markup for it. I even sold a couple knives to make room in my budget for these 85s...

I was disappointed upon inspection of the knife. I like a firm pull, about a 7 is perfect for me. The dead skunk I had came with a perfect 7 main blade and maybe a 7.5 cap lifter. This knife, though, had an 8 main blade and a hitched solid 9 on the caplifter. I use my knives a lot, and was worried I wouldn't want to use this one, especially after overpaying for it and selling a couple other terrific knives just to buy it.

Anyway, I started digging up the old threads where I remembered people discussing pull weights. I never had luck with the "open halfway" method actually lightening a spring. But, there were other ideas...

(this is the knife post modification, as I didn't think about taking more pictures during the process.)

In this post, @sitflyer discusses using a file or sandpaper to take some off the tang. A challenging maneuver because the bladewell is so narrow. A challenge I was willing to take on. Upon inspection of my knife, it had a burr on the tang, so removing the burr helped the initial impossible "hitch" in opening.

In this post, @Phil Gibbs discusses rehafting the spring side of the handle to remove material from the springs, stating that this would lighten the pull. Inspecting my knife, I saw that the blades were not flush at open anyway, because the tops springs were higher than the tops of the blade tangs. @Bill DeShivs corroborated Phil's suggestion in this post, so I bellied up and busted out my 1x30" belt.

I also decided to add the small nail nick access notch with a Dremel wheel. It's not an EO like we're used to seeing on these 85s from GEC, but it is nice to better position the thumbnail to press upward into the nick rather than have to pull at a perpendicular. My caplifter was set pretty low in the handle, so this offers a lot more room.

In the end, the pulls on this knife are now pretty close to the pulls on my Dead Skunk 85, a solid 7 on the main and about a 7.5 on the caplifter. As I do not like the satin finish GEC puts on their bolsters and shields, I went ahead and polished these up on this knife. I achieved the same finish on the backsprings as GEC applies from the factory (which is better than trying to polish those things, IMO - the steel takes forever to get the grinder marks out of, and doing high polish always ends up leaving some visible lines that to my eye make the backside of the knife look incomplete.)

I'm sharing because this isn't the first time I've encountered a nailbreaker on a knife I wanted to love, but it is the first time that I had this much money into one and didn't want to sell it and look for another. I wanted to share the success because I've heard others talk about this difficulty with some of their knives, and my hunch is that there will be another member or two with the gumption to try this someday.

- Andrew

I was disappointed upon inspection of the knife. I like a firm pull, about a 7 is perfect for me. The dead skunk I had came with a perfect 7 main blade and maybe a 7.5 cap lifter. This knife, though, had an 8 main blade and a hitched solid 9 on the caplifter. I use my knives a lot, and was worried I wouldn't want to use this one, especially after overpaying for it and selling a couple other terrific knives just to buy it.

Anyway, I started digging up the old threads where I remembered people discussing pull weights. I never had luck with the "open halfway" method actually lightening a spring. But, there were other ideas...

(this is the knife post modification, as I didn't think about taking more pictures during the process.)

In this post, @sitflyer discusses using a file or sandpaper to take some off the tang. A challenging maneuver because the bladewell is so narrow. A challenge I was willing to take on. Upon inspection of my knife, it had a burr on the tang, so removing the burr helped the initial impossible "hitch" in opening.

In this post, @Phil Gibbs discusses rehafting the spring side of the handle to remove material from the springs, stating that this would lighten the pull. Inspecting my knife, I saw that the blades were not flush at open anyway, because the tops springs were higher than the tops of the blade tangs. @Bill DeShivs corroborated Phil's suggestion in this post, so I bellied up and busted out my 1x30" belt.

I also decided to add the small nail nick access notch with a Dremel wheel. It's not an EO like we're used to seeing on these 85s from GEC, but it is nice to better position the thumbnail to press upward into the nick rather than have to pull at a perpendicular. My caplifter was set pretty low in the handle, so this offers a lot more room.

In the end, the pulls on this knife are now pretty close to the pulls on my Dead Skunk 85, a solid 7 on the main and about a 7.5 on the caplifter. As I do not like the satin finish GEC puts on their bolsters and shields, I went ahead and polished these up on this knife. I achieved the same finish on the backsprings as GEC applies from the factory (which is better than trying to polish those things, IMO - the steel takes forever to get the grinder marks out of, and doing high polish always ends up leaving some visible lines that to my eye make the backside of the knife look incomplete.)

I'm sharing because this isn't the first time I've encountered a nailbreaker on a knife I wanted to love, but it is the first time that I had this much money into one and didn't want to sell it and look for another. I wanted to share the success because I've heard others talk about this difficulty with some of their knives, and my hunch is that there will be another member or two with the gumption to try this someday.

- Andrew