DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

Can't beat the price of a good plate, they will leave a rougher cut which some like cause it makes the edge more toothy and slices more aggressively at the given grit yet some also dislike this feature since it reduces the push cutting that a smoother finish at the same grit size accentuates in displacing material better.

A rougher finish will also reduce edge stability to a degree.

They may not need to be flattened but the major disadvantage is they wear out and are disposable, it's just a single layer of abrasive grains so when they go they go. Some will argue that they have had their plate for +20 years and still cuts although if a more discerning user got to try the same plate it would be obviously worn well past it's life cycle and no longer cutting efficiently or at the same grit it once was.

It is recommended they be used with light touch to prolong the grain life and avoid tear out but eventually all things wear away and the cutting facets of the diamond wear down and break down over time with use even if tear out is avoided.

I personally prefer bonded stones resin, metallic and vitrified. They have a renewable surface, better surface finish and less prone to tear out. They can cost more due to the stone volume needing to be filled with diamond as well as some of the manufacturering cost of some of the more exotic bonds and machining.

Vitrified is my favorite

A rougher finish will also reduce edge stability to a degree.

They may not need to be flattened but the major disadvantage is they wear out and are disposable, it's just a single layer of abrasive grains so when they go they go. Some will argue that they have had their plate for +20 years and still cuts although if a more discerning user got to try the same plate it would be obviously worn well past it's life cycle and no longer cutting efficiently or at the same grit it once was.

It is recommended they be used with light touch to prolong the grain life and avoid tear out but eventually all things wear away and the cutting facets of the diamond wear down and break down over time with use even if tear out is avoided.

I personally prefer bonded stones resin, metallic and vitrified. They have a renewable surface, better surface finish and less prone to tear out. They can cost more due to the stone volume needing to be filled with diamond as well as some of the manufacturering cost of some of the more exotic bonds and machining.

Vitrified is my favorite

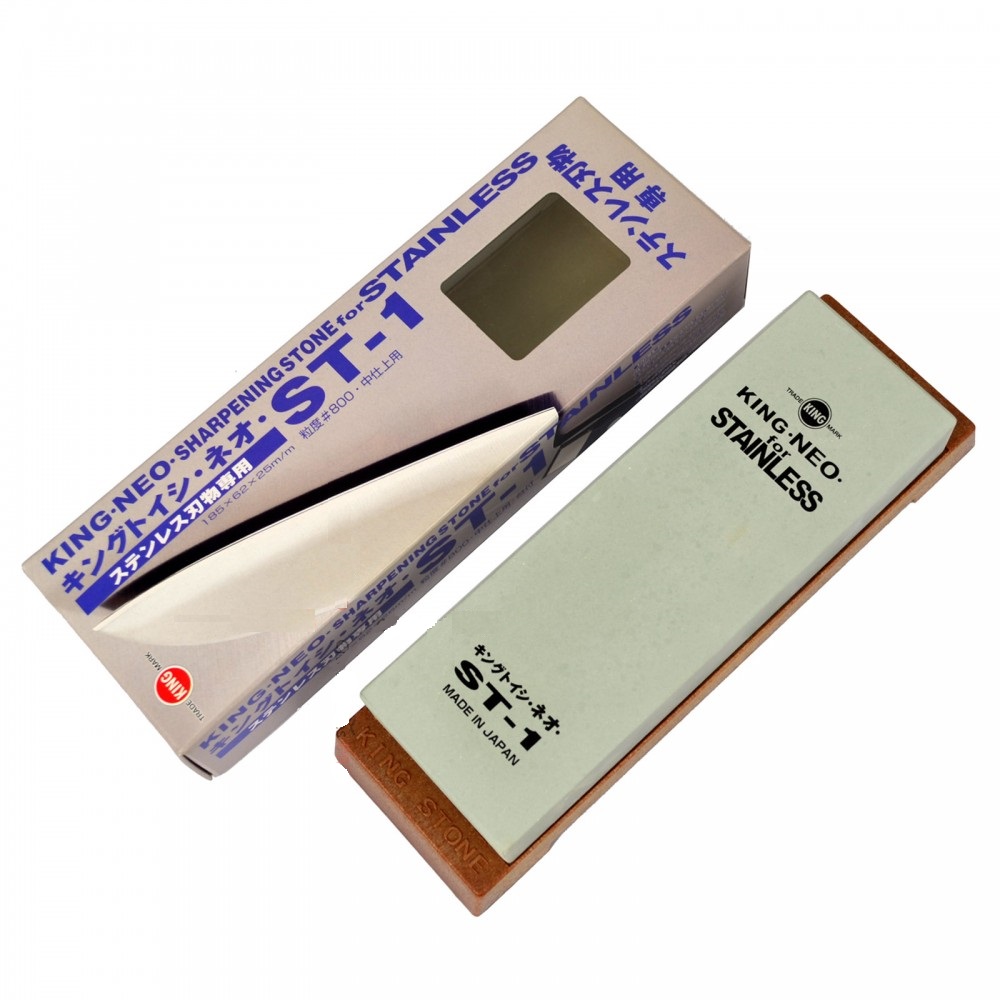

I've been looking to get a good multi-purpose stone that works a bit quicker than the 1000 grit King stone I have. I was looking at this one and I was also considering a 1200 grit eze lap. They are both fairly similar in price where I am.

Honestly I was leaning towards the diamond(more because it requires no water, doesn't need flattening, and cleans easily), but I read this link from one of the stickies in this forum and am now a bit hesitant. That link seems to say that even very fine grit diamond stones are not a good choice. What's your take on this?

Love your work by the way. I have learned a lot from your youtube channel and posts here, so thank you.

Edit: I also want something that I can use with Maxamet and M4 etc

Last edited: