-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knife recommendation for tire guy

- Thread starter David Richardson

- Start date

Rupestris

Gold Member

- Joined

- Mar 1, 2006

- Messages

- 29,677

Another vote for a utility knife.

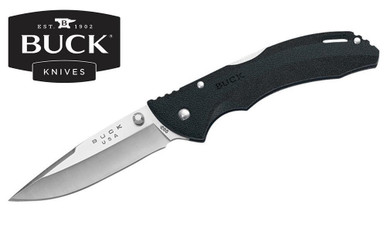

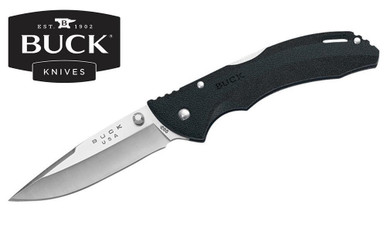

If I were going with a folding knife, I'd lean heavily toward a Buck Bantam 285. US made, hollow ground 420HC by BOS and you can find them at online retailers or in big box stores for $20. Sometimes less.

If you check Buck's website under Web Specials, you can sometimes find them for ~$16 (but you do pay shipping there).

If I were going with a folding knife, I'd lean heavily toward a Buck Bantam 285. US made, hollow ground 420HC by BOS and you can find them at online retailers or in big box stores for $20. Sometimes less.

If you check Buck's website under Web Specials, you can sometimes find them for ~$16 (but you do pay shipping there).

mechanics' and tire guys' "working" knives are going to get used , abused and trashed. i'd go with an inexpensive sturdy liner lock knife or an out the front , ala "lightning". a shop isn't the best place for a knife you want to keep for years. i've bought a mechanic friend some good quality knives. they don't hold up to the rigors of scraping, stabbing holes in something, etc. his knives are considered disposables.

King of the Cheese

Stillborn!

- Joined

- May 25, 2016

- Messages

- 76,186

Honestly I wouldn’t spend a lot. It sounds like he’s going to abuse it, so I’ll echo the opinion that he use a utility blade. If you want to get him something nice, get a 8cr13mov Kershaw for $25 (Cyber Monday deals are good). On the cheaper end, maybe a cheap “jar-o-knives” he could throw away when they get too beat up and pull out another. But if it were me, I’d use a utility blade. Any knife that is going to be banged against metal will not look pretty, and I’ll assume he doesn’t have the luxury of time needed to sharpen out chips and rolls.

- Joined

- Jun 29, 1999

- Messages

- 10,069

A heavy duty Olfa would probably work for him.

- Joined

- Nov 30, 2018

- Messages

- 503

Thanks for all the comments. Very helpful. I think I'm going to gift him one of beater Buck Vantages for now to see how it likes it. One of the CS knifes are also good options.

Right. He has almost no sharpening skills. He doesn't want to take the time to learn. This is another reason a utility knife is a great idea.can he sharpen or will you be sharpening his knives?

I agree with all above who said utility knife, but also a nice knife to carry out of work, I've gifted some decent knives to people I work with but also seems like I'm sharpening them very often for them

Another thought is maybe a multi tool

Agree. I think he wants a nice knife. He has not yet realized that his job is not the place to use it. Maybe I'll get him a Delica or Endella for Christmas after he figures out what he needs for work.I wouldn't go too expensive just in case it gets lost. With that being said as a truck mechanic I use a Kershaw 7777 and it holds up great and sharpens decent around 70 bucks.

100% agree. I went down this path with him. He's clearly going to use a knife regardless. If you've ever had success convincing a 20 year old of something, please let me know how you did it. (FYI, I have 4 kids and my youngest just turned 18. I eventually learned that the more advice I give the less likely they are to take it.)Side cutter pliers. A knife is just an accident waiting to happen here.

K390 is not where I would go. For me, yes. For him, not enough toughness and he won't be able to sharpen it. He'll need better skills and new stones. He's not a knife guy.Delica or Endela in K390

If you've ever had success convincing a 20 year old of something, please let me know how you did it.

Nope. Unpossible.

afishhunter

Basic Member

- Joined

- Oct 21, 2014

- Messages

- 14,918

Agree.The first knife that comes to my mind is a Buck 110.

Inexpensive so you don't mind beating on it.

Easy to sharpen.

Very solid build.

Classic and not threatening to coworkers/customers.

Good corrosion resistance for the price (I'm sure it is going to be exposed to all manner of fluids and gunk).

They are heavy knives to be sure, but they are real work horses.

I used a (post 2000 420HC) Buck 110 when I worked in a mechanic shop, and when I was a fabrication welder and heavy equipment mechanic.

The 110 Cut hoses, valve stems (under the rim. Above the rim has a brass insert under the rubber), scraped head, oilpan and other gaskets, scrape grease/oil/dirt off the oilpan, valve covers, and wherever else needed, cut fan belts, stripped wire, cut cardboard, scored drywall when remodeling the office, everything I needed to cut, scrape, or score. Also worked well during deer season to peel and field dress the whitetail we harvested.

Holds a working edge, most times a dry strop (boot top or belt work well) or butcher's steel was all that as needed to maintain the working edge. It was rare to need a sharpening stone. Could I shave with it? Probably not. (1) I never learned to shave with a straight razor. (2) I quit the nasty, vile, disgusting, expensive 3 double edge safety razor blades each shave shaving habit a week or two before graduating highschool, in 1974.

The 110 and 112 are not afraid of a little hard work/use.

- Joined

- Nov 30, 2018

- Messages

- 503

I could be wrong, but I don't think I'm confusing the two. K390 has great edge retention/wear resistance. Better than M390, which is saying a lot. But it does not have great toughness. I'm more concerned about an edge chipping or breaking than I am about how long it will stay sharp.Don’t get K390 confused with M390.

K390 is a tool steel, holds an edge and is easy to sharpen

I've never seen K390 described as easy to sharpen. I have a few K390 knives and have reprofiled them. I would not want to do this without diamond or CBN stones. M390 is 4% vanadium. K390 is 9%.

I have been a mechanic and owned a shop for decades. An auto repair shop is a torture chamber for knives.

I suggest a cold steel folder or a griptilian. I usually use a HK folder made by benchmade. No super high end steel. m390, s110v, M4 all dull or chip the same as CPM154 if you hit a brake rotor opening a box or the frame of a car removing a zip tie. But a more common steel is way easier to sharpen or regrind. And less brittle.

A partially serrated blade is great for mechanics because the serrations strip wire, cut zip ties and cut plastic better than a straight edge. Nothing too fine point. I nave broken a couple of spydercos.

Take the pocket clip off or cover it with a couple of layers of heat shrink so he doesnt get in trouble for scratching cars with it. Get him a good pocket screwdriver so he doenst use the knife.

I suggest a cold steel folder or a griptilian. I usually use a HK folder made by benchmade. No super high end steel. m390, s110v, M4 all dull or chip the same as CPM154 if you hit a brake rotor opening a box or the frame of a car removing a zip tie. But a more common steel is way easier to sharpen or regrind. And less brittle.

A partially serrated blade is great for mechanics because the serrations strip wire, cut zip ties and cut plastic better than a straight edge. Nothing too fine point. I nave broken a couple of spydercos.

Take the pocket clip off or cover it with a couple of layers of heat shrink so he doesnt get in trouble for scratching cars with it. Get him a good pocket screwdriver so he doenst use the knife.

Buy him a valve stem puller and maybe some other tools and a reasonably priced spyderco, Benchmade, crkt, or something you think he'd like. Banging a harder tougher steel into customers rims is not cool. He shouldn't need to cut valve stems. If he's going to be a mechanic he's better off slowly acquiring tools to do the job right. Cutting boxes or the odd object here and there is one thing, but using the knife for everything is a good way to get seriously injured and that may have repurcussions for his career depending on how professional of a place he works at.

- Joined

- May 29, 2004

- Messages

- 3,044

The Cold Steel tuff lite is one of my absolute favorite knives and I think it fits the bill:

Inexpensive (no big deal if it gets thrashed)

Hollow grind

Super easy to sharpen

Extremely high cutting pressure can be exerted due to the grind, shape, handle, and short length. This would go through tire rubber better than any other folder I own.

Small so not threatening, but handle design actually not bad for SD role.

I use mine extensively in crafting/leather work. It’s easily my most used and sharpened folder…

Get a few - they’re great!

DocJD

Basic Member

- Joined

- Jan 29, 2016

- Messages

- 12,305

I agree with those that advocate for a inexpensive working knife .

Either a utility knife with disposable blades or a tough , inexpensive Cold Steel working knife or similar .

An expensive knife is likely to be damaged ,lost or stolen in that environment . And is not really necessary ,IMO . Just an added worry for a job site .

Either a utility knife with disposable blades or a tough , inexpensive Cold Steel working knife or similar .

An expensive knife is likely to be damaged ,lost or stolen in that environment . And is not really necessary ,IMO . Just an added worry for a job site .