-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Myths About Damascus - Edge Retention, Sharpness, and History

- Thread starter Larrin

- Start date

- Joined

- Mar 31, 2018

- Messages

- 2,766

I don’t know much about Damascus or pattern welded steels other than it usually contains mild and high carbon steels. The only other thing I know is the 1989 model Buck 110 Damascus Stag that I have is among the sharpest knives I have ever had and holds an edge for a very long time. I lost count the number of deer and other game I have processed over the years and clean,oil and strop it after each use. I’ve only touched it up a few times and it still looks new. So scary sharp it will cut you just looking at it. Lol. I have other knives in s30v, 154cm and vg10 and the Damascus does as well as any of them it just needs cleaning and oil.

- Joined

- May 28, 2012

- Messages

- 3,189

Any Damascus steel being made by newer steels like a combo of Cruwear and S35vn?

http://blog.bladeops.com/what-is-cpm-s35vn-steel.html

https://www.bladehq.com/cat--Best-Knife-Steel-Guide--3368

http://blog.bladeops.com/what-is-cpm-s35vn-steel.html

https://www.bladehq.com/cat--Best-Knife-Steel-Guide--3368

Last edited:

Larrin

Gold Member

- Joined

- Jan 17, 2004

- Messages

- 5,049

Damascus combos have to be compatible both in terms of etching for contrast and for heat treatment. That usually means they need to have overlapping austenitizing temperatures and similar final hardness, though matching hardness may not be a requirement.

- Joined

- Mar 8, 2008

- Messages

- 26,212

Since we're here discussing damascus and the question recently came up...where does Damasteel fall in this discussion?

~Chip

That's just pattern-welded.

- Joined

- Jan 6, 2016

- Messages

- 1,012

... Was Bill Moran the first to "rediscover" pattern welded steel?

It wasn't all that lost. There are some absolutely beautiful pattern welded barrels on high-end shotguns and double rifles made up through the mid 1800s or so. (one source says "The manufacture of spiral welded gun barrels in pattern-welded damascus steel, was a huge industry for over 100 years, ending around 1930. ")

http://firearmshistory.blogspot.com/2010/05/barrel-making-early-barrel-making-in_29.html

http://firearmshistory.blogspot.com/2010/05/barrel-making-pattern-welded-or.html

pics of some barrels: http://firearmshistory.blogspot.com/2010/06/barrel-making-pattern-welded-or_06.html

http://www.hallowellco.com/leue +Timpe.htm

It's a fair conclusion that pattern wielded damascus was in near continuous production in Germany during the 20th century -

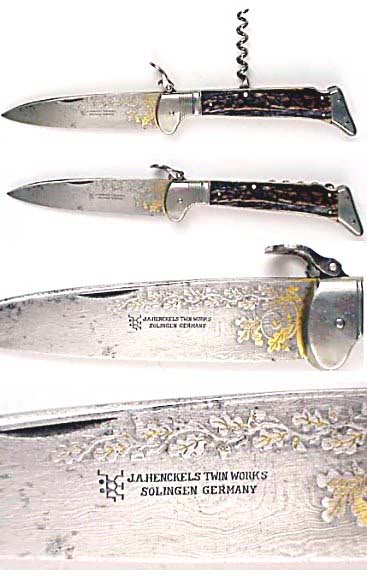

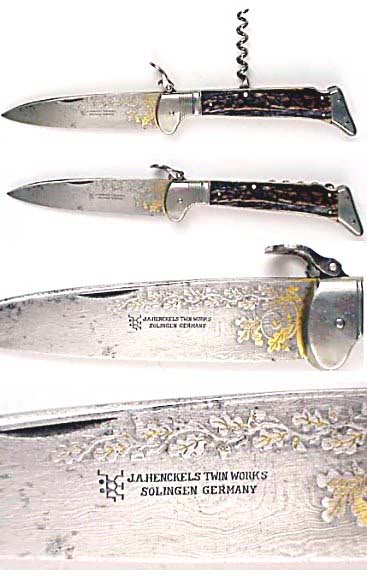

Henckels from the late 1800's - 1930's cataloged deluxe jagdmesser and hirschfager like the below -

.

.

Other German examples -

1903 - http://www.warrelics.eu/forum/sword...rd-445293/?s=b16463747540a2ed88b28c74f04e55a9

1933 - http://www.johnsonreferencebooks.co...w-outstanding-dedicated-damascus-blade-30427/

1937 - http://www.icollector.com/Rare-Thir...utlass-with-Herman-Goring-Dedication_i9387032 .

I'm sure if one tried they could fill in all the decades of the 20th century with German damascus examples.

Henckels from the late 1800's - 1930's cataloged deluxe jagdmesser and hirschfager like the below -

Other German examples -

1903 - http://www.warrelics.eu/forum/sword...rd-445293/?s=b16463747540a2ed88b28c74f04e55a9

1933 - http://www.johnsonreferencebooks.co...w-outstanding-dedicated-damascus-blade-30427/

1937 - http://www.icollector.com/Rare-Thir...utlass-with-Herman-Goring-Dedication_i9387032 .

I'm sure if one tried they could fill in all the decades of the 20th century with German damascus examples.

Last edited:

Wowbagger

Gold Member

- Joined

- Sep 20, 2015

- Messages

- 8,047

I enjoyed that IMMENSELY ! ! !I wrote an article on a handful of Damascus steel myths

THANK YOU ! ! ! !

I have always questioned (in my mind) the usefulness of layering steel like that at the edge. To me it seemed weak and inferior.

On the other hand cladding a ductile but toughened steel on each side of a superior edge holding but some what brittle steel has always garnered my interest.

In my experience modern makers who do this "don't get it" though. They make the blade as thick or thicker than a similar blade of one steel type. The advantage in my mind is to make a thinner blade that has superior resistance to catastrophic failure (snapping in half) yet has excellent hardness.

I suppose that is another thread entirely.

Great job ! ! !

Keep up the very generous posts to educate us laymen.

Up until this point I never realized that the layers could be formed from cycling the temps; I always thought it was from layering of two or more alloys.

I have a few clad knives / cutting tools and enjoy the look immensely.

In particular I have one knife that has some layering of nickel and it is a stunner and surprisingly dirt cheep; I think I paid fifty some dollars for it. I also have this lovely Temple Builder's chisel that was up around five hundred dollars when I bought it a decade ago. I love this look !

https://www.google.com/search?clien....gws-wiz-img.obupw4gfOc4#imgrc=UUbcsOS7IcBJjM:

Wowbagger

Gold Member

- Joined

- Sep 20, 2015

- Messages

- 8,047

Nice oneThese were also far superior to modern metallurgy with all its silly science and microscopic analysis and whatever.

- Joined

- Jun 29, 1999

- Messages

- 10,046

Great article, thanks. I am still looking for a Damascus/Wootz blade that can shear through an anvil and then still shave.

Wowbagger

Gold Member

- Joined

- Sep 20, 2015

- Messages

- 8,047

Well everyone knows that the only "right" way to make a blade is to go out into outer space, turn around and set a tangential course for Earth, get up to speed . . . you know . . . one or two hundred thousand miles an hour, then jettison a container of nicely mixed elements and wait for the pretty blue white light, snatch the last remains from the atmosphere just before it vaporizes, cool'er down a little bit and bang the thing on the anvil until it fits one's idea of an EDC shape.What about meteorite?

Piece of pie !

Of course my Tanngrisnir does make all this ridiculously easy.

https://hitchhikers.fandom.com/wiki/Tanngrisnir

- Joined

- Jul 27, 2015

- Messages

- 4,666

One question has always plagued me about Damascus/pattern welded steel. I’ve raised the issue before and never gotten a real answer, but I assume this is a thread that will get a significant number of eyes on it from people who really know Damascus steel, so I'll ask it now.

Damascus steel is two or more steels all pounded and folded together over and over and then ground into a knife shape and HTed right? So since each individual steel that makes up the Damascus has its own optimal HT that brings out the best properties of that steel, how can one ever really do a "best practice" HT on Damascus steel? It would seem that the best you can do is pick steels to fold/pound that have relatively similar heat treats and then perform a heat treat that does a decent job on all, but not the best for any one of them in particular.

We make a huge deal here about how edge geometry and HT are as important if not more important than which steel you pick. Right? Because, just as an example, an excellently HTed VG10 could very well outperform a lousy HT on S90V, etc...

So ultimately, the question is, can a Damascus blade ever get optimal HTs for the steels of which it is made, or will it always just be a compromise? Obviously this question doesn't apply in cases with a single steel core, and Damascus laminated layers either side (i.e., Spyderco Damascus Delica with a VG10 core).

Larrin

Gold Member

- Joined

- Jan 17, 2004

- Messages

- 5,049

I gave a very short answer in post #24. You're combining a lot of different questions with things like heat treatment vs steel for performance, compatibility of heat treatment, etc. It's a lot to answer. I was hoping you might have some follow up questions. Austenitizing temperature is the big one for heat treatment compatibility.

kuraki

Fimbulvetr Knifeworks

- Joined

- Jun 17, 2016

- Messages

- 4,679

He may just not know which questions to ask. To narrow that field down I have a few regarding the common 15n20/1084 mix specifically.

How much carbon migration goes on between two alloys like 15n20 and 1084 during pattern welding?

Is there a point in a typical pattern welded blade where the two layers become close to homogeneous (time, temp, layer count)?

Even if there is such a point, what is the practical difference between "ideal" HT for 15n20 and 1084?

Would you expect it to even be discernible after pattern welding to a relatively common layer count, say ~300?

How much carbon migration goes on between two alloys like 15n20 and 1084 during pattern welding?

Is there a point in a typical pattern welded blade where the two layers become close to homogeneous (time, temp, layer count)?

Even if there is such a point, what is the practical difference between "ideal" HT for 15n20 and 1084?

Would you expect it to even be discernible after pattern welding to a relatively common layer count, say ~300?

- Joined

- Jul 27, 2015

- Messages

- 4,666

I gave a very short answer in post #24. You're combining a lot of different questions with things like heat treatment vs steel for performance, compatibility of heat treatment, etc. It's a lot to answer. I was hoping you might have some follow up questions. Austenitizing temperature is the big one for heat treatment compatibility.

Ahhh yes, I do see that. I didn't realize it was addressing my question.

I guess ultimately, it sounds like the heat treats have to be compatible, and I figured as much, but compatible for the two steels (assuming it's just two steels) and optimal for both steels are two different things. You can do a decent job on HT and call a blade hardened, or you can do an optimal job* and get the best properties out of the steel you're working with.

What my question boils down to is are there any two steels that can be combined for a Damascus that would both have the same optimal HT so that your blade is getting the best of both steels it incorporates? Or is it always going to be a compromise of HTs that are "compatible" and merely good enough?

I hope I'm being articulate enough to get my question across clearly. if not I'm happy to clarify further.

*Yes i realize that optimal can mean optimizing for hardness, toughness, or whatever other property you're looking for. I don't need to give a specific one in this example, because the question remains the same regardless of what we are trying to optimize.