- Joined

- Oct 19, 2005

- Messages

- 19,961

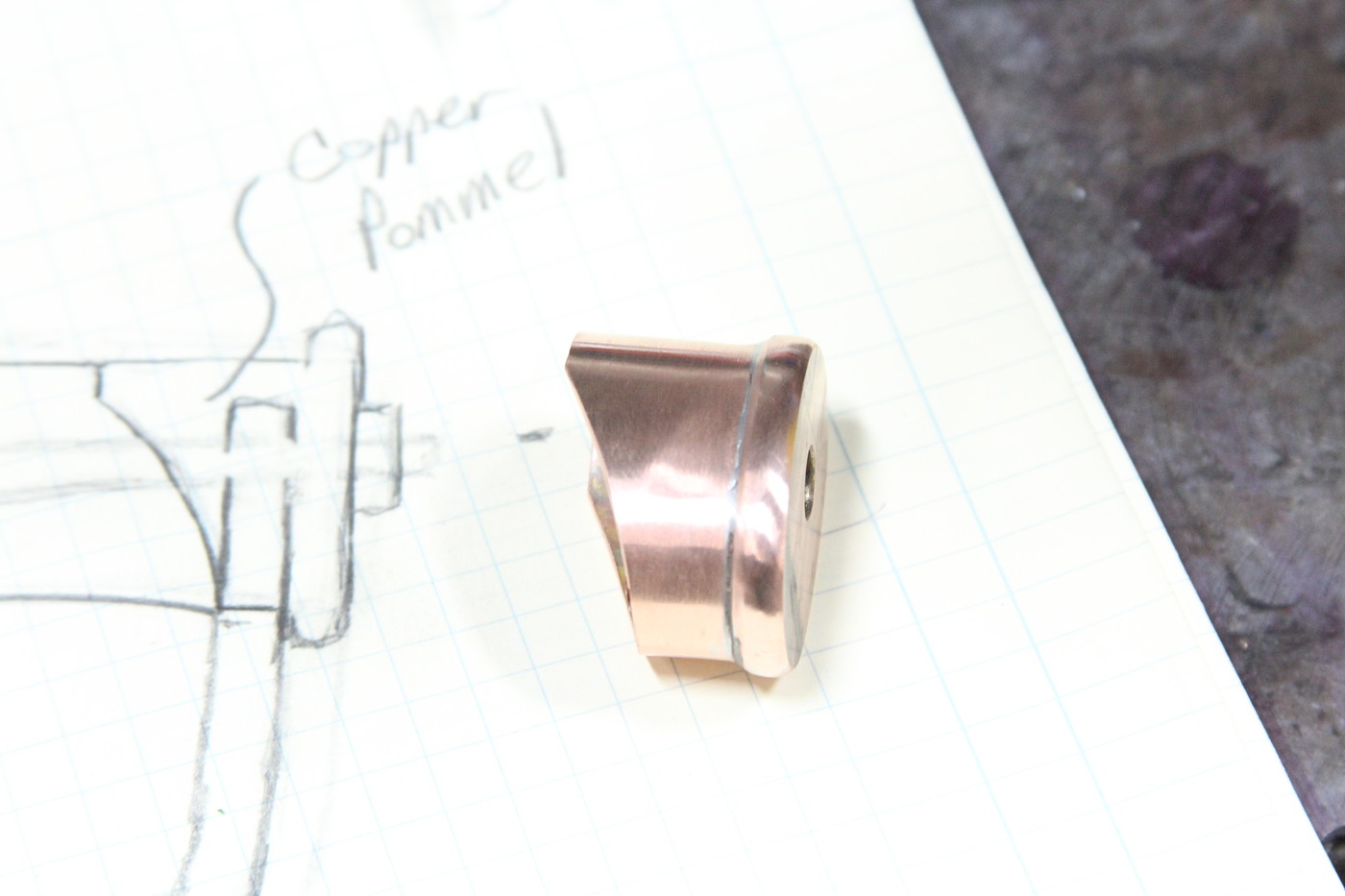

I made a Pommel for the sword yesterday. Today I will start on the micarta scales. OD green canvas for this first one as its what I have in stock.

I am trying to be very conscious of weight. We have taken measurements as we have gone along and they are below.

Blade - .84 lbs

-Raw bar - 3.5 lbs

-Profiled blank - 1.42 lbs

-Surface ground (to put in the beginnings of the distal taper) - 1.12 lbs

-After fuller grinding and basic edge grinding (ready for heat treat) - 0.84 lbs

Guard after hammering and slotting for blade - 0.54 lbs

Pommel and mounting ring - 0.12 lbs

Total weight so far - 1.5 lbs

While that is not bad, my goal is to stay under two lbs, I will eventually be able to reduce the weight of everything but the blade. The ideal weight of the blade I plan to base on historical examples which I feel can't be bettered. That is to say modern materials will not allow for weight reduction while the handle material and guard can be made lighter and stronger than the historical examples with titanium and burlap micarta or carbon fiber. Steel still weighs what steel did then. I have already ordered the titanium for the guard and pommel. I'll have to learn a lot about balance before I design the 3rd piece. The 3rd piece is the one I will start looking to finishing details, and final materials. Once I finish this first one, I plan to break it.

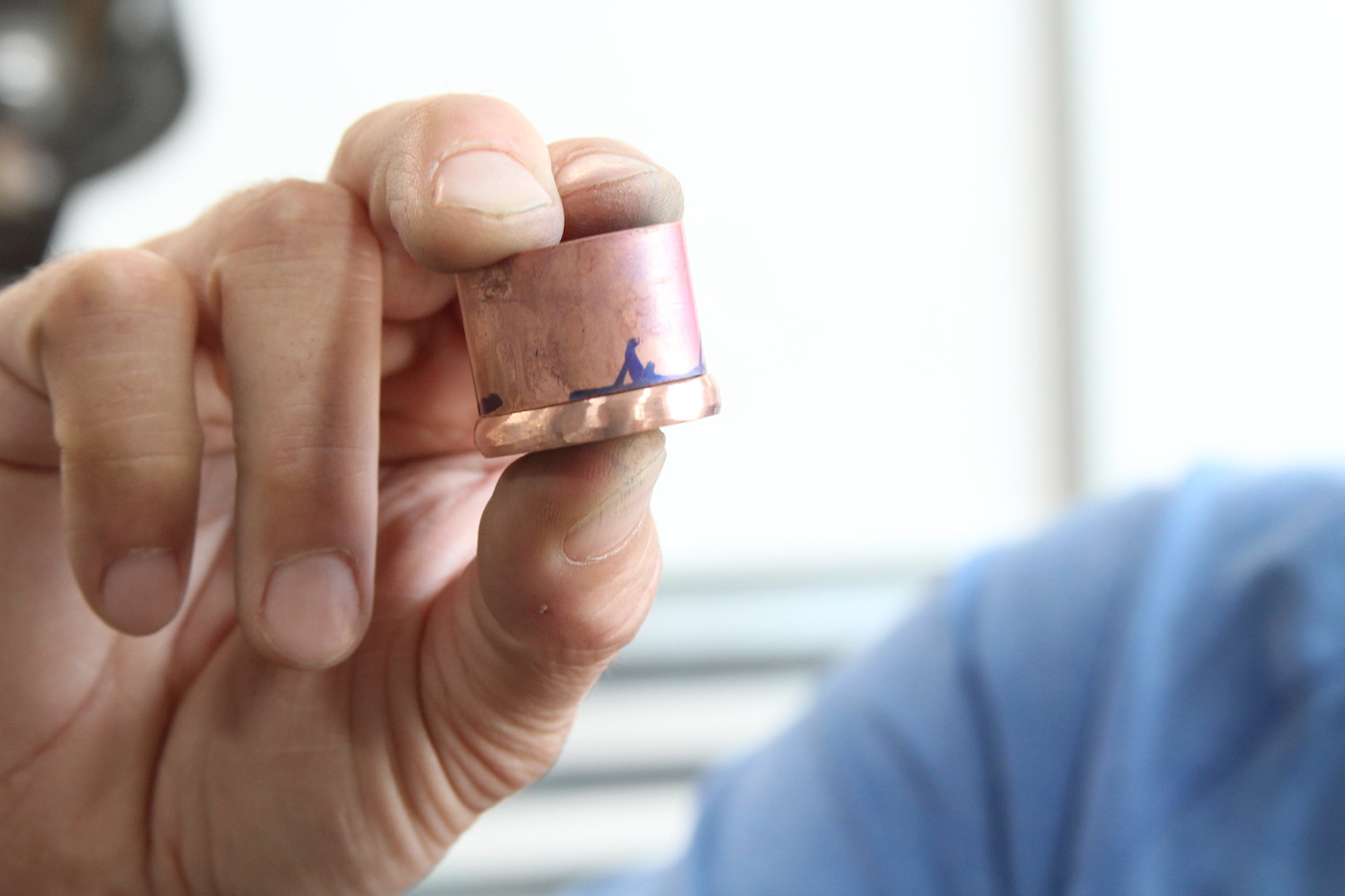

The pics below show the pommel being made. The process in a run on is to anneal the pipe and bend to shape, trace the shape onto sheet stock and cut out leaving a smidge extra, round and shape the cap then solder and finally put the cutout toward the front of the sword.

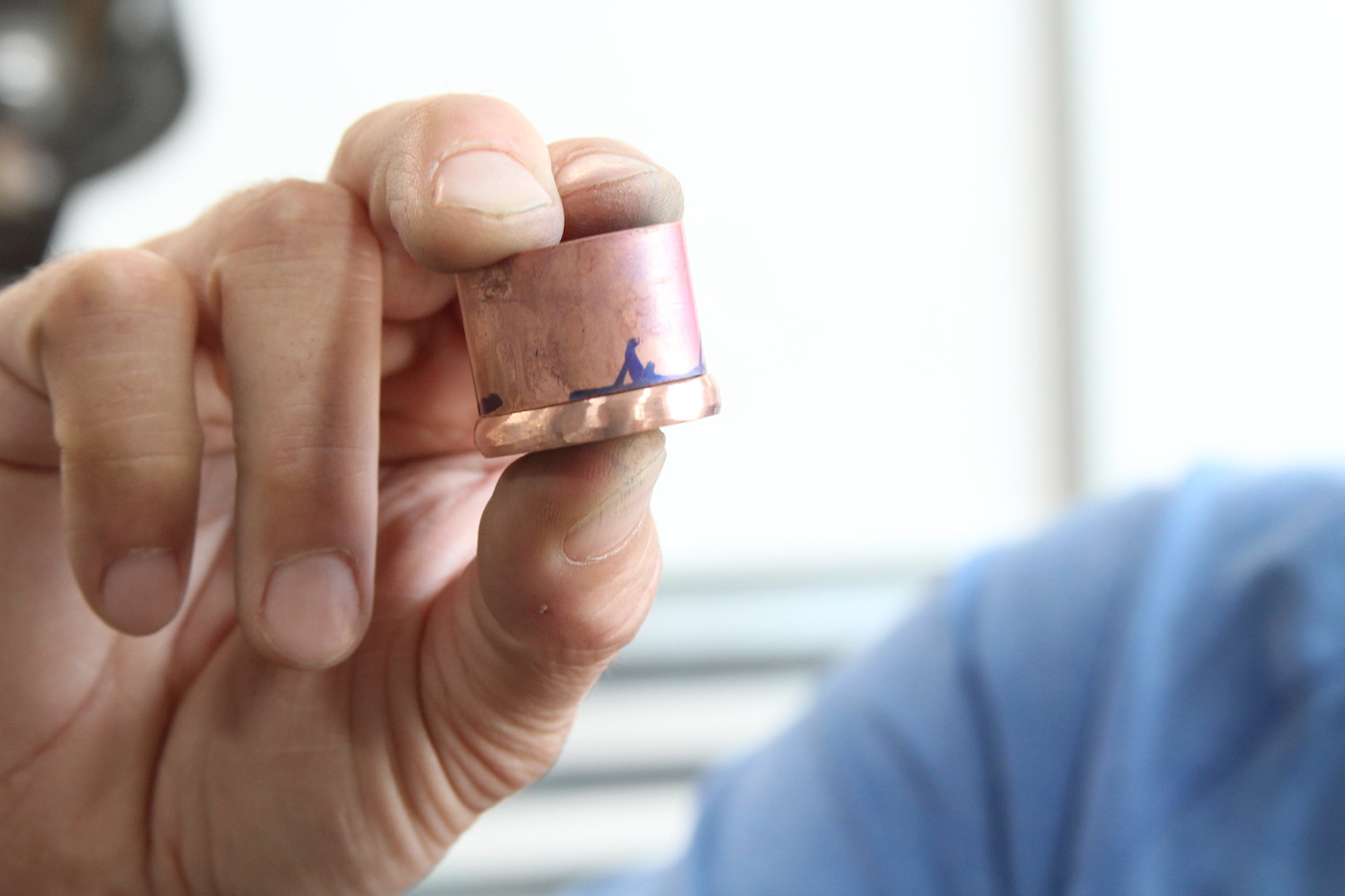

This is the stackup ready to be soldered.

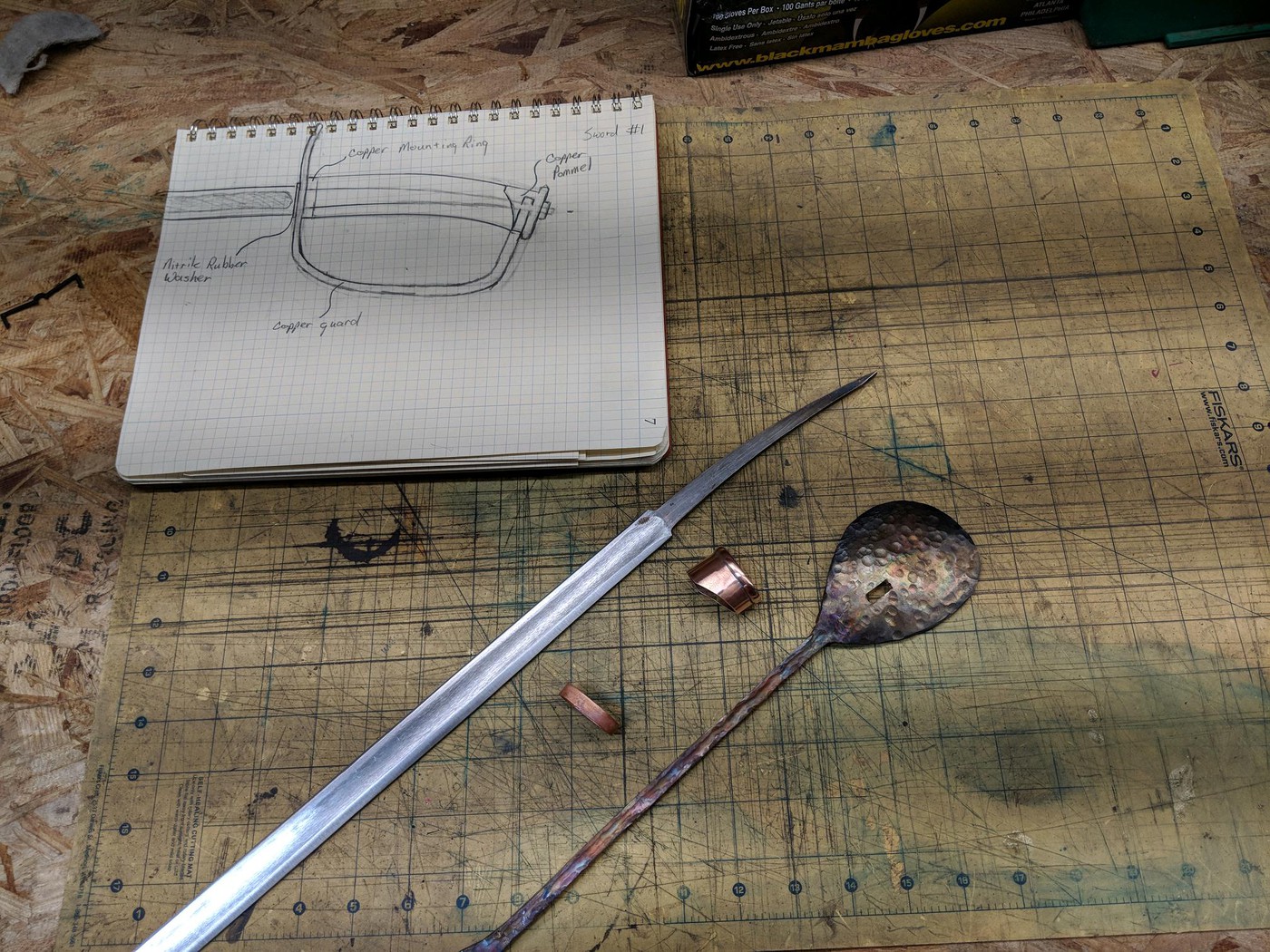

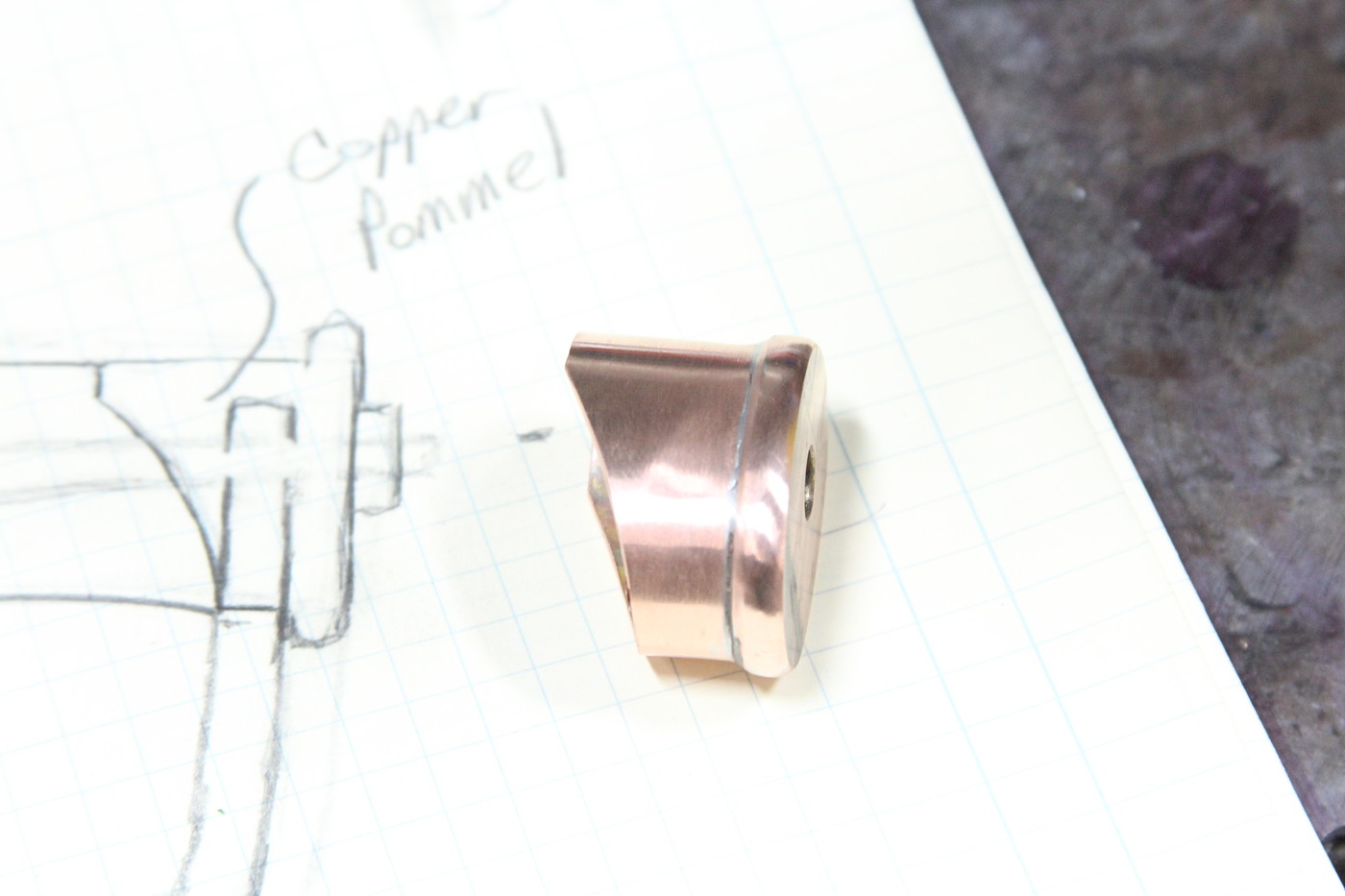

This one shows a bunch of the not good enough, ones and experiments in tubing sizes I did. It also shows the 1 to 1 ratio handle stackup drawing for this sword. There still has to be a notch cut into the pommel to accept the strap from the guard.

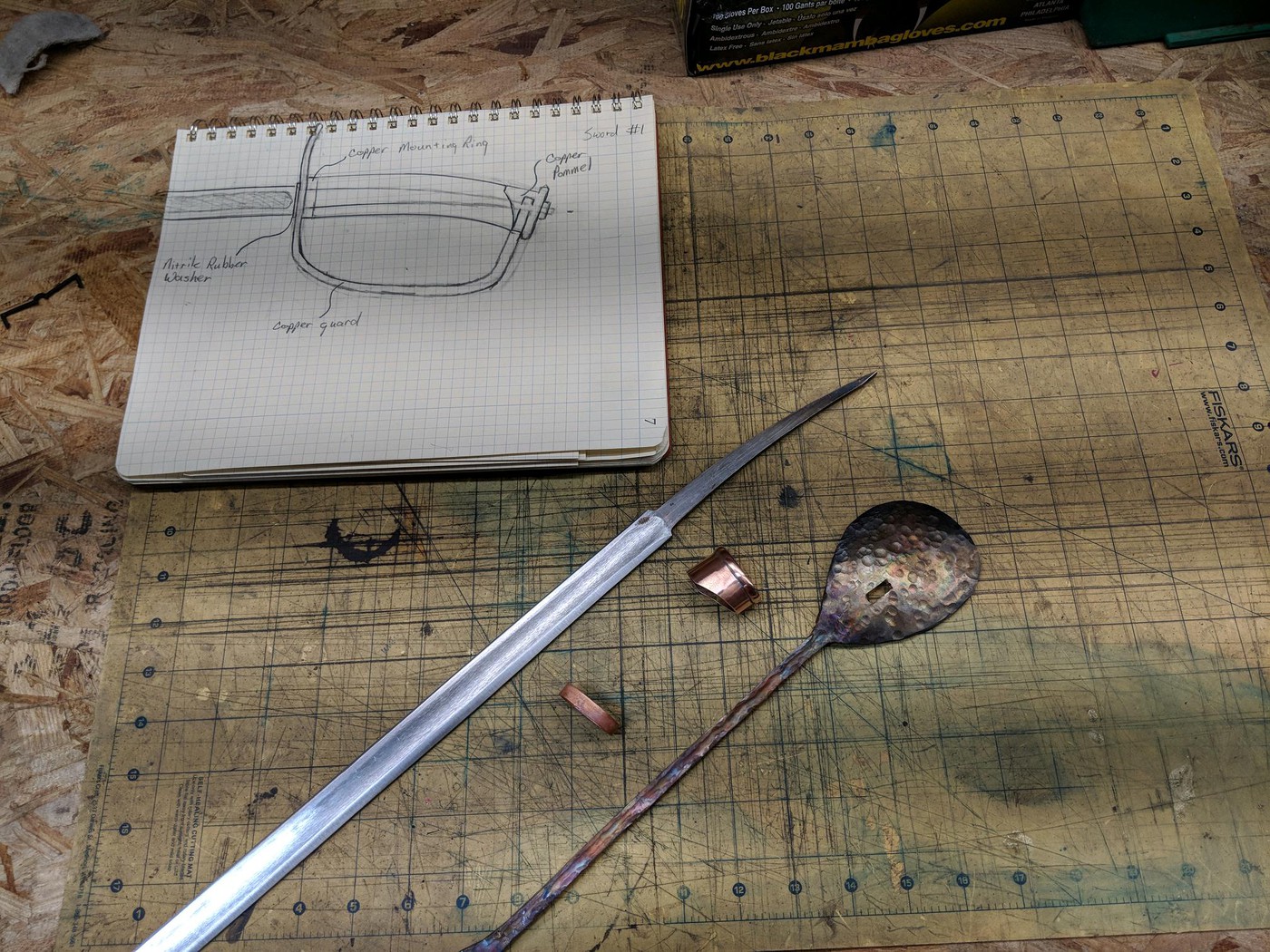

This one is just all the parts so far and the drawing.

I am trying to be very conscious of weight. We have taken measurements as we have gone along and they are below.

Blade - .84 lbs

-Raw bar - 3.5 lbs

-Profiled blank - 1.42 lbs

-Surface ground (to put in the beginnings of the distal taper) - 1.12 lbs

-After fuller grinding and basic edge grinding (ready for heat treat) - 0.84 lbs

Guard after hammering and slotting for blade - 0.54 lbs

Pommel and mounting ring - 0.12 lbs

Total weight so far - 1.5 lbs

While that is not bad, my goal is to stay under two lbs, I will eventually be able to reduce the weight of everything but the blade. The ideal weight of the blade I plan to base on historical examples which I feel can't be bettered. That is to say modern materials will not allow for weight reduction while the handle material and guard can be made lighter and stronger than the historical examples with titanium and burlap micarta or carbon fiber. Steel still weighs what steel did then. I have already ordered the titanium for the guard and pommel. I'll have to learn a lot about balance before I design the 3rd piece. The 3rd piece is the one I will start looking to finishing details, and final materials. Once I finish this first one, I plan to break it.

The pics below show the pommel being made. The process in a run on is to anneal the pipe and bend to shape, trace the shape onto sheet stock and cut out leaving a smidge extra, round and shape the cap then solder and finally put the cutout toward the front of the sword.

This is the stackup ready to be soldered.

This one shows a bunch of the not good enough, ones and experiments in tubing sizes I did. It also shows the 1 to 1 ratio handle stackup drawing for this sword. There still has to be a notch cut into the pommel to accept the strap from the guard.

This one is just all the parts so far and the drawing.