- Joined

- Oct 20, 2008

- Messages

- 5,547

Sorry for the bad pun. Now-

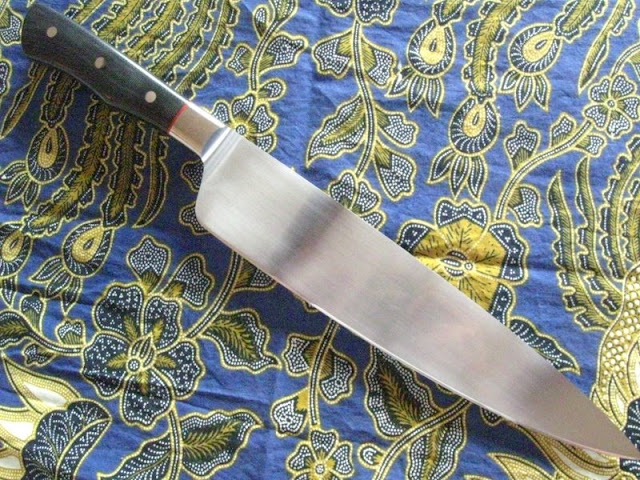

Here's my latest integral chef. It's forged from CruForgeV, a high vanadium carbon steel designed with the bladesmith in mind. Takes a nasty sharp edge with very good retention. Full flat grind with mild convexity toward the edge, distal taper.

Handle is mortised construction, all three SS corby bolts are through the hidden tang. Scales are black canvas phenolic with a red fiber spacer.

Hand sanded to 600 grit, mirror polished razor edge.

This blade is ground to achieve food release- i.e., potatoes, onions and the like stick to the blade minimally if at all. As with all my kitchen knives, I did some test cutting with it before posting here. It's extremely sharp and push cuts tomatoes well, dices potatoes with minimal wedging and negligible sticking. However, this knife is not a "laser"- it's a bit more all purpose/robust than that. Use your laser edge knives to slice garlic paper thin, and this one to take apart a chicken and prep your vegetables. I don't believe in a one-blade-fits-all chef knife, but this is my general user type. Feels nice, solid and comfy in the hand. Edge has a continuous mild rocking curve.

Measurements are as follows:

Cutting edge 10-3/8"

Overall length 16.5"

Blade height at heel 2-1/8"

Max spine thickness .105"

Uniform handle thickness 3/4"

Edge before sharpening .020, sharpened at 8 deg./side

Balance point is at the torch in the trademark.

Asking price is $260 U.S. SOLD, FUNDS RECEIVED. Price includes shipping to 50 states. I will ship around the world; I just ask that in this case the buyer pay the added shipping costs.

Here's some pics.

I make knives to the best of my ability and knowledge. I research to find the best materials and methods to use, in order to provide the very best product, in terms of value, durability, performance, and aesthetics. Should you find a knife you have bought from me to be lacking in any of these respects, you may ship it back to me at my expense for a full money-back return.

Should a knife purchased from me fail in materials or workmanship, please ship it back to me at my own expense for your money back in full, or repairs at no cost. Its your choice.

I will sharpen any of my knives at no cost; however I do ask that you pay for shipping costs for this service.

I am always pleased to hear from any of my customers, past, repeat, potential, or otherwise. Please go to my web site, see "Contact Me" and give me a call. If you have any questions regarding these policies, I'd like to hear them.

Also, if this knife or any other I have made that you have seen looks close to something you would like, or if you would like to talk about an entirely different knife design altogether, please contact me, I do custom orders as well and always enjoy talking about knife designs, whether or not we actually end up doing business.

Salem Straub

Here's my latest integral chef. It's forged from CruForgeV, a high vanadium carbon steel designed with the bladesmith in mind. Takes a nasty sharp edge with very good retention. Full flat grind with mild convexity toward the edge, distal taper.

Handle is mortised construction, all three SS corby bolts are through the hidden tang. Scales are black canvas phenolic with a red fiber spacer.

Hand sanded to 600 grit, mirror polished razor edge.

This blade is ground to achieve food release- i.e., potatoes, onions and the like stick to the blade minimally if at all. As with all my kitchen knives, I did some test cutting with it before posting here. It's extremely sharp and push cuts tomatoes well, dices potatoes with minimal wedging and negligible sticking. However, this knife is not a "laser"- it's a bit more all purpose/robust than that. Use your laser edge knives to slice garlic paper thin, and this one to take apart a chicken and prep your vegetables. I don't believe in a one-blade-fits-all chef knife, but this is my general user type. Feels nice, solid and comfy in the hand. Edge has a continuous mild rocking curve.

Measurements are as follows:

Cutting edge 10-3/8"

Overall length 16.5"

Blade height at heel 2-1/8"

Max spine thickness .105"

Uniform handle thickness 3/4"

Edge before sharpening .020, sharpened at 8 deg./side

Balance point is at the torch in the trademark.

Asking price is $260 U.S. SOLD, FUNDS RECEIVED. Price includes shipping to 50 states. I will ship around the world; I just ask that in this case the buyer pay the added shipping costs.

Here's some pics.

I make knives to the best of my ability and knowledge. I research to find the best materials and methods to use, in order to provide the very best product, in terms of value, durability, performance, and aesthetics. Should you find a knife you have bought from me to be lacking in any of these respects, you may ship it back to me at my expense for a full money-back return.

Should a knife purchased from me fail in materials or workmanship, please ship it back to me at my own expense for your money back in full, or repairs at no cost. Its your choice.

I will sharpen any of my knives at no cost; however I do ask that you pay for shipping costs for this service.

I am always pleased to hear from any of my customers, past, repeat, potential, or otherwise. Please go to my web site, see "Contact Me" and give me a call. If you have any questions regarding these policies, I'd like to hear them.

Also, if this knife or any other I have made that you have seen looks close to something you would like, or if you would like to talk about an entirely different knife design altogether, please contact me, I do custom orders as well and always enjoy talking about knife designs, whether or not we actually end up doing business.

Salem Straub

Last edited: