Alex Topfer

Gold Member

- Joined

- May 1, 2019

- Messages

- 767

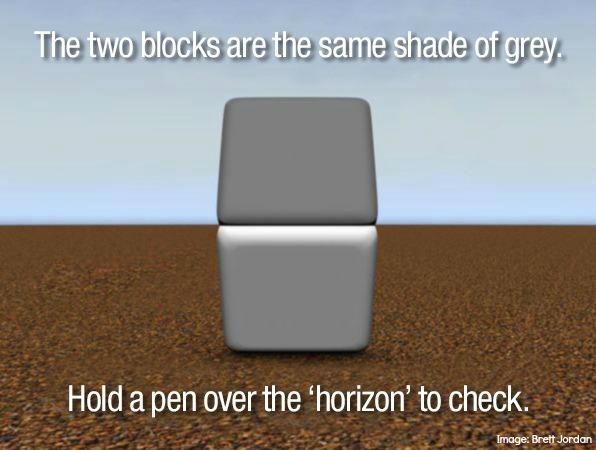

human perception is very relative. how you see a colour will be dependent on the other colours around it, lighting, your expectations of what the colour will be. Our brains just don't work in a way that generates accurate readings of the world.Can you write a bit more about why checking for glow color when the TC is placed directly on the steel would not give accurate results?

IMO, you can get around this with a l o t of practice (years, decades? i'm testing this), but if you're just interested in getting a precise result it's easier to use a thermometer of some type.

Edit: here's a shade perception visual illusion as an example

Last edited: