Hi all, sorry I didn't know about this thread sooner otherwise I'd have responded; thanks to Butch for letting me know.

To that point, I'd like to clarify a few things:

1) These tests began after I received a sudden series of reports from people reading threads on social media of others claiming to be plate quenching carbon steels, particularly 52100, 5160, and 1095. I do heat treat customer support for New Jersey Steel Baron and with these claims, I put it to test as, as butch clearly highlighted, we don't need more snakeoil or hype in knives.

2) Tests were conducted at NJSB during my recent trip to Aldo's in part for access to a recently, properly calibrated Rc machine, fresh stock, and a surface grinder--for example to exclude the possibility of case hardening, samples were surface ground to 220 grit with .060 material removed. Furthermore, I have the certs for all steels tested, so I was assured composition, the annealed state, and legitimacy of the materials.

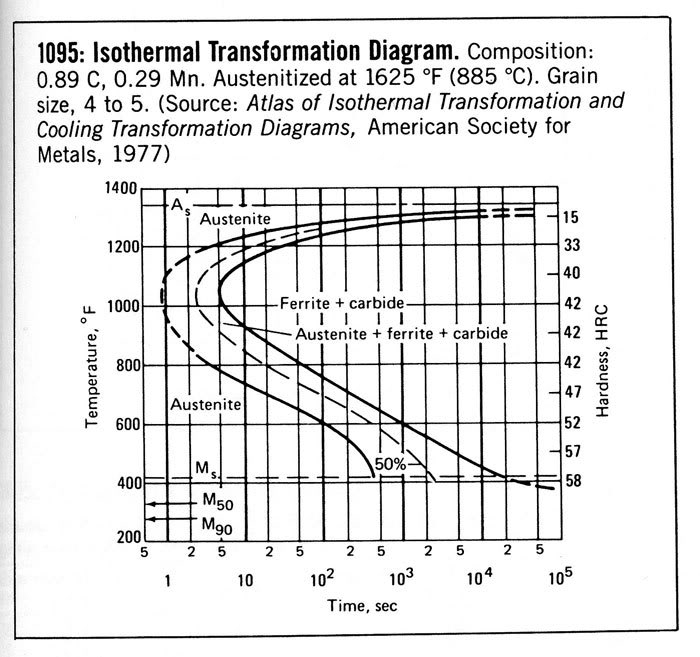

3) BluntCut and Mete specifically state my concerns--despite HRC readings, micrographs and tests must be taken to check elongation and the greater possibility there's a mixture of pearlite, bainite, etc. with martensite, which as noted will not make a serviceable edged tool. While I am not a classically trained metallurgist, the stated claims made little sense to me aside rather old reports of Nicholson plate quenching C10130 and 1095 files, and those are hearsay. That's why I took it upon myself to do testing--to ensure consistency in some aspect of minimal, preliminary testing and that samples be sent to a proper lab for thorough examination before progressing any further.

To be frank, I am VERY skeptical of the results, this was a maneuver to do some preliminary controlled testing in light of other people posting in support of this practice.

It is all too easy for someone to try this, break a sample, and post pictures of fine grain and say, "it works" when we know that what can be seen with the naked eye does not mean there is not mixed structure. While I do understand the enthusiasm many people have about this, it is imperative to be objective and logical without making assumptions. It could very well be as Geoff put it--a cute party trick, but not one that properly hardens a blade.

What is important is this:

I am trying my best to send early samples to a lab for testing, I have them with me and once I find a reputable, certified lab to review them, will send them off.

I understand more than anything else that faking anything along these lines jeopardizes my credibility and once I have results from an accredited lab, will post their results and name with it--sources count a lot for the reliability of the information.

Since posting the videos mentioned by the OP, I have more than once told people the aforementioned factors publicly on the original threads--I am not endorsing or advocating plate quenching carbon steels until we have proper lab results.

Until we know what's going on inside the steel I tested, it's a novelty, not an alternative.