There is no point almost in any thing we do here ....I'm not saying it's not possible or even far fetched, just not sure what the point is of going to that much trouble to avoid a burr.

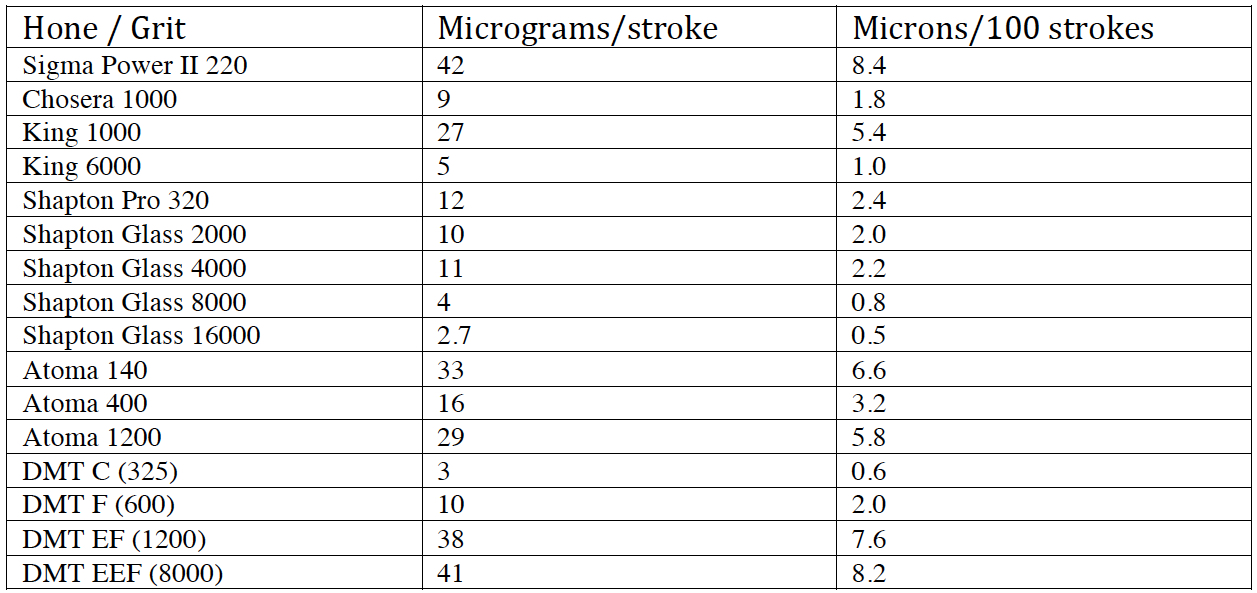

from going through 5 or 6 exotic expensive stones and 3 or 4 strops to polish the edge on exotic japanese knives

to

edge retention hysteria searching for most exotic powder steel with as high as possible vanadium and tungsten content

and to

trying to achieve so sharp edge it will cut you just standing close to the knife.

If you go back to basics and the purpose having a knife .... all we need is a knife made of reasonable steel with reasonable edge so we can cut something.

But; this is a hobby so there is no point looking for a point. You won't find a rational explanation for most things people do around here with their knives and edges.