Hello there

I am writing this with heavy heart and tears in my eyes

So, here is the story.

For days now I was telling my dear wife how great of the knife master hunter 3v is.

Normally, she just smiles and nods not paying much attention as she finds my knife hobby a bit childish.

Today, for a change, she decided to pay me a bit more attention and actualy asked if she could use my knife to prepare meal while I will be picking our daughter from nursery.

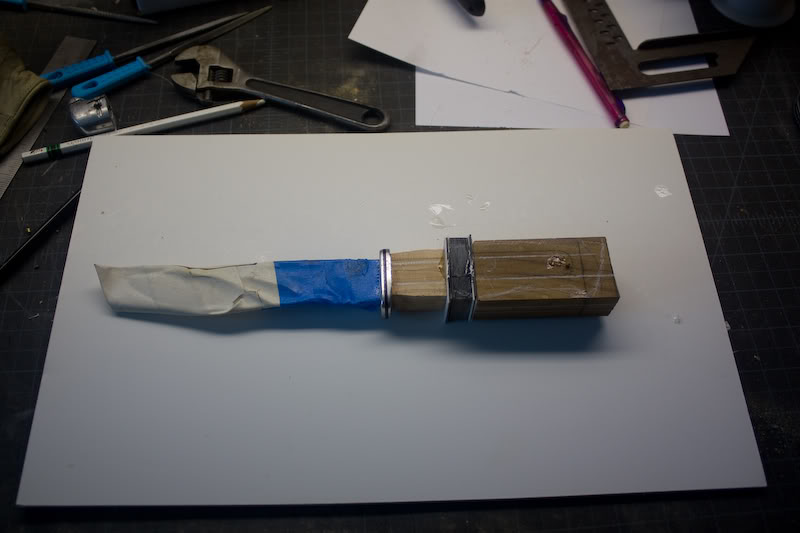

So, when I got back, I was met with "Please dont get mad". I shall spare you details but sufgice to say she have managed to burn and melt kraton handle

I have already removed it entirely and currently sitting in the garden with a bit of fire on and a glass of jd contemplating and trying to put a possitive spin on the whole situation.

I will have to come with the idea of the new handle so I though I would ask my fellow knife aficionados and seek wise counsel in that matter.

Regards

Michal

I am writing this with heavy heart and tears in my eyes

So, here is the story.

For days now I was telling my dear wife how great of the knife master hunter 3v is.

Normally, she just smiles and nods not paying much attention as she finds my knife hobby a bit childish.

Today, for a change, she decided to pay me a bit more attention and actualy asked if she could use my knife to prepare meal while I will be picking our daughter from nursery.

So, when I got back, I was met with "Please dont get mad". I shall spare you details but sufgice to say she have managed to burn and melt kraton handle

I have already removed it entirely and currently sitting in the garden with a bit of fire on and a glass of jd contemplating and trying to put a possitive spin on the whole situation.

I will have to come with the idea of the new handle so I though I would ask my fellow knife aficionados and seek wise counsel in that matter.

Regards

Michal