- Joined

- Feb 17, 2009

- Messages

- 7,310

I hate them on a flat platen but they really excel on a wheelI've tried regular Trizact but don't like them at all. I had people tell me they're great and better than Norax because they last a long time.

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

I hate them on a flat platen but they really excel on a wheelI've tried regular Trizact but don't like them at all. I had people tell me they're great and better than Norax because they last a long time.

Likewise I'm not sure but my guess would be the actual ceramic used and it's fracture properties may actually preclude the.. structuring if you would?Well when I said the thing about ceramic abrasive, I was talking about having it in a structured for like a trizact (rather than in a cubitron structured abrasive style) for potentially better results finishing hard material, like the stuff we work with.

As far as I can tell, there is only one type of the trizact belts that are sic. The rest like the popular among knife maker, gator grit are structured aluminum oxide.

I'm aware they are very intensely engineered. Which is what my comment about not know everything that goes into the engineering of these belts involves. Meaning I doubt I would have a full understanding of the testing, physics, chemistry, and general planning that it takes to create these belts.

Which I was also meant towards my idea that a ceramic alumina (trizact gator grit style) structured abrasive may not be ideal, or even possible. In a way that is either financially feasible, or physically realistic.

As far as I know, ceramic aluminium oxide is little more than regular aluminium oxide particles sintered together. The finer you get the less advantage there is to the sintered particle. A bigger particle can fracture revealing a sharp point more times before it's worn down to a blunt nub. I have used plenty of ceramic aluminium oxide j-flex belts from Hermes and Klingspor in 240 and 400 grit e.g. CS931JF, and it's hard to distinguish them from plain aluminium oxide J-Flex.Likewise I'm not sure but my guess would be the actual ceramic used and it's fracture properties may actually preclude the.. structuring if you would?

No, ceramic generally means particles sintered together. Individual aluminium oxide grains are corundum crystals, like rubies and sapphires.Isn't plain old aluminum oxide technically a "ceramic"? Zirconia? Silicon carbide?

Do we know the actual material on a Norax? The brochure is a little sketchy about it.

The U936 norax are ceramic, most of the others are aluminum oxide.Isn't plain old aluminum oxide technically a "ceramic"? Zirconia? Silicon carbide?

Do we know the actual material on a Norax? The brochure is a little sketchy about it.

Okay here goes idiot talk - I thought ceramic was actual ceramic particulates not ceramic bonded al2o3? I may be wrong likewise not sure here lol but. I really do not think that its al2o3 bonded with ceramic....lets use this stupid internet thing. I use 980 for removal and trizact for finishing. j weighted al2o3 for any further finishing and of course al2o3 scallops for handles.As far as I know, ceramic aluminium oxide is little more than regular aluminium oxide particles sintered together. The finer you get the less advantage there is to the sintered particle. A bigger particle can fracture revealing a sharp point more times before it's worn down to a blunt nub. I have used plenty of ceramic aluminium oxide j-flex belts from Hermes and Klingspor in 240 and 400 grit e.g. CS931JF, and it's hard to distinguish them from plain aluminium oxide J-Flex.

I think the structured abrasives on Trizact Gator and Norax belts are the best we are going to get. As I mentioned before they're easy to refresh with a file card or wire brush.

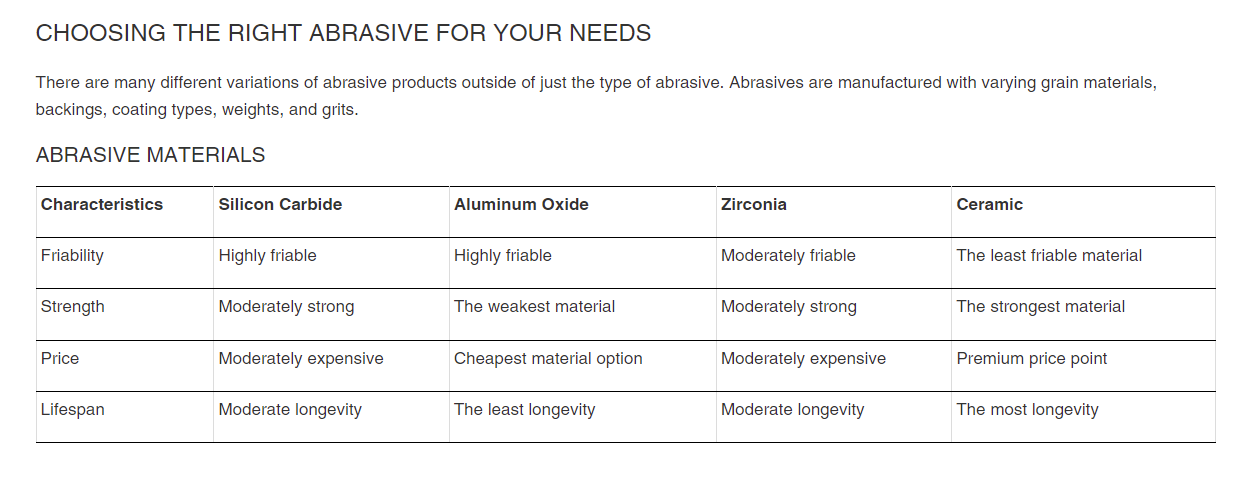

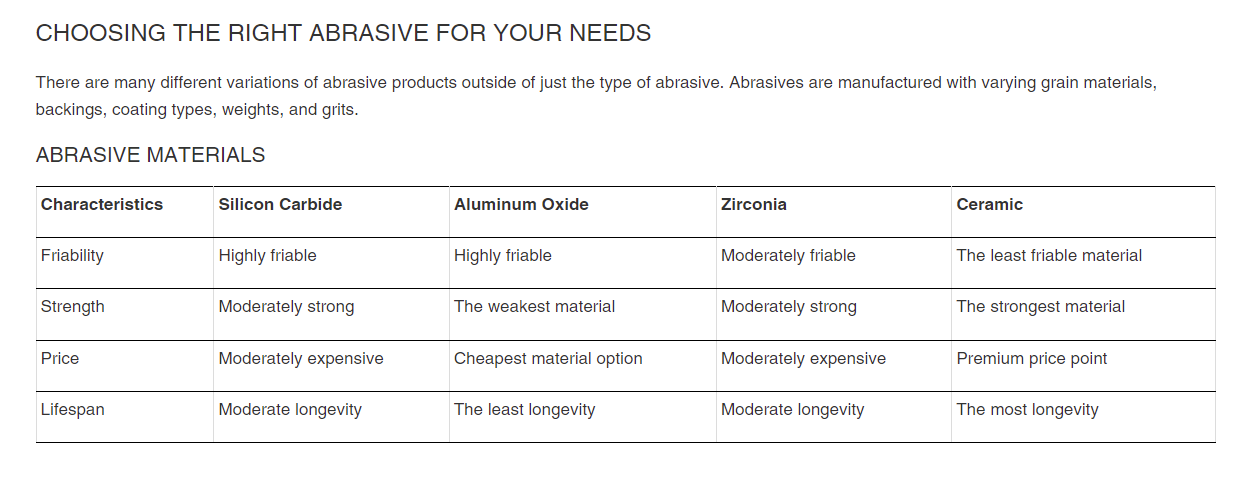

www.redlabelabrasives.com

www.redlabelabrasives.com

No sir ceramics are a unique class of materials! THE ONE THING I CAN ANSWER!Isn't plain old aluminum oxide technically a "ceramic"? Zirconia? Silicon carbide?

Do we know the actual material on a Norax? The brochure is a little sketchy about it.

Also are you positive on the ceramic being al2o3 binded with ceramic? I ask a lot of questions, sorry mate lol.Blankblank

Check the Red Label Abrasives website - there is some good info there that my posts won't show because of the links.

I just checked out the stuff on the red label abrasives site talking about different abrasives, and I didn't see anything said on ceramics that clashed with what the all about abrasives article said. Also I didn't see anywhere mention that ceramic abrasive is just al2o3 binded with ceramic, on either site.Also are you positive on the ceramic being al2o3 binded with ceramic? I ask a lot of questions, sorry mate lol.

Why I ask -

All About Abrasives

May 9, 2007

Dates.

Oh ya sorry man I didn't mean that question for you it was the guy that mentioned it. I probably should re-read em but im. 99.99999% sure its pure ceramic? May be wrong and I'd like to know lol..Also I didn't see anywhere mention that ceramic abrasive is just al2o3 binded with ceramic, on either site.

I'm honestly kind of thinking he was mixing the structured ceramic abrasive into the equation. Like the vsm structured ceramic abrasives someone mentioned, are ceramic aluminum oxide. That are basically grain that are sintered (I'm guessing) or bonded together to form a larger abrasive grain that fracture off in a more controlled way. 3m also had the cubitron structured ceramic abrasive that I believe is sort of the same deal.Oh ya sorry man I didn't mean that question for you it was the guy that mentioned it. I probably should re-read em but im. 99.99999% sure its pure ceramic? May be wrong and I'd like to know lol..

What makes me so certain? Is the wording and the way it's described.

It says varying grain materials, and then proceeds to list each one separately.... Obviously that. Is not a factual answer? But it seems like it at least?

Oh of course ceramic al2o3 is different. How? It's bonded with ceramic! Don't ask me how exactly such as if it's actual mixed al2o3 with ceramic and then fired (could that be done? I think that al2o3 has a really high melting point but I'd have to check) and is part of the abrasive or if it's some kind of ceramic resin but I am likewise pretty sure that those would not be in use now and that ceramic like r980 is just pure ceramic that has better frangibility? Than things in the past. The reason I said the date thing is because from that time until now while technology hasn't really changed so much it's improved and more affordable for different purposes. Abrasives however.. how do I make anything without abrasives?I'm honestly kind of thinking he was mixing the structured ceramic abrasive into the equation. Like the vsm structured ceramic abrasives someone mentioned, are ceramic aluminum oxide. That are basically grain that are sintered (I'm guessing) or bonded together to form a larger abrasive grain that fracture off in a more controlled way. 3m also had the cubitron structured ceramic abrasive that I believe is sort of the same deal.

However from the reading I've been doing, it looks more and more like ceramic aluminum oxide is different from just aluminum oxide. Much like the different grades they listed in the article I listed. I'm just not sure exactly in what way it's different.

The cubitron structured abrasive is more like triangular prism shaped ceramic pieces. At least from what I've seen looking at my sandpaper under a microscope I have. (Hey i find it interesting, I also took a bunch of pictures of other abrasives magnified and posted them on another forum).Oh of course ceramic al2o3 is different. How? It's bonded with ceramic! Don't ask me how exactly such as if it's actual mixed al2o3 with ceramic and then fired (could that be done? I think that al2o3 has a really high melting point but I'd have to check) and is part of the abrasive or if it's some kind of ceramic resin but I am likewise pretty sure that those would not be in use now and that ceramic like r980 is just pure ceramic that has better frangibility? Than things in the past. The reason I said the date thing is because from that time until now while technology hasn't really changed so much it's improved and more affordable for different purposes. Abrasives however.. how do I make anything without abrasives?Not sure there! And yes I also know cubitron is I guess cubes but I didn't know that it was ceramic. Who's used cubitron and what for exactly? I know thats more of a research myself thing. I will. Just curious I doubt that I'll change belts. And yeah man I think that I misunderstood what he was trying to get at. Nice chatting with you however

I gots some research to do

Okay here goes idiot talk - I thought ceramic was actual ceramic particulates not ceramic bonded al2o3? I may be wrong likewise not sure here lol but. I really do not think that its al2o3 bonded with ceramic....lets use this stupid internet thing. I use 980 for removal and trizact for finishing. j weighted al2o3 for any further finishing and of course al2o3 scallops for handles.

I thought I had seen 3m call their cubitron structured abrasive ceramic in their own literature. It certainly looks like what i would call a ceramic abrasive under magnification (nothing crazy, just 50-100x)I've spoken to sales reps and product managers from Hermes, Klingspor, Saint-Gobain (Norton), and 3M, and none of them have given me a straight answer on what exactly ceramic aluminium oxide is or how it's made, so I think it's fairly proprietary and secret.

My inference is that it's probably aluminium oxide particles sintered together by heating them to a point at which they will bond to each other but not so hot that they fuse into an amorphous solid, leaving them with pre-existing fracture points that will leave a new sharp point when they break.

Information from Klingspor on their new CS922Y belt specifies:

"From Aluminium oxide to Ceramic by a special manufacturing process and sintering. This process produces a Ceramic grain that is pressure-resistant, with fine Crystalline structure (microcrystalline,)"

It's possible some other material is present bonding the particles together, like how cobalt is used in cemented tungsten carbide, but I haven't seen any information that indicates another substance is involved.

The 3M guys also insist that Cubitron isn't ceramic, it's a different, better, more proprietary and secretive technology. I've been really impressed with how 36 grit Cubitron belts grind but found their optimal grinding life was short, at least for how I grind, as the abrasive particles wore unevenly at the edges of the belt. They had plenty of life left for rough profile grinding but were no good for bevelling.

www.sciencedirect.com

www.sciencedirect.com