- Joined

- Oct 20, 2008

- Messages

- 5,547

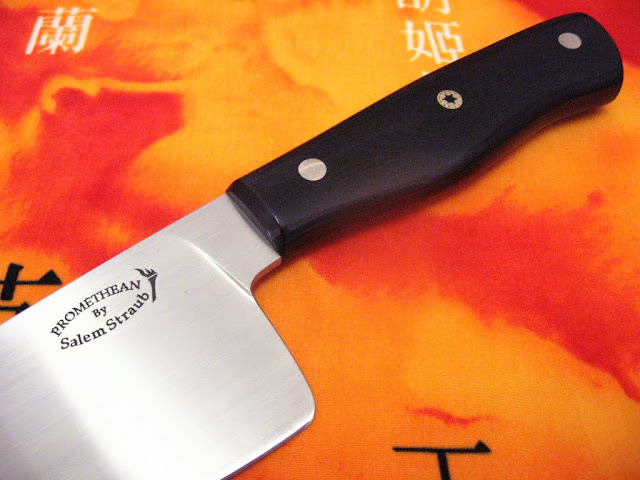

Here's a new model of mine. It's nothing fancy, just a solid no frills carbon chef knife, designed for hard use and cutting utility. I want one for my kitchen! Just shipped this to a customer today.

Materials: 52100 alloy blade, G10 mortised handle with stainless and mosaic pins.

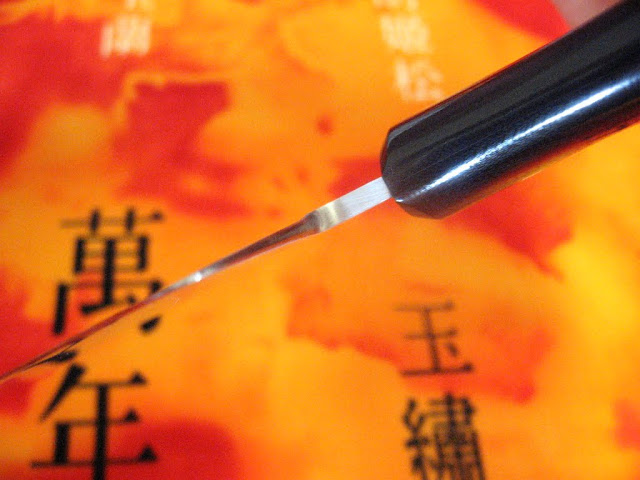

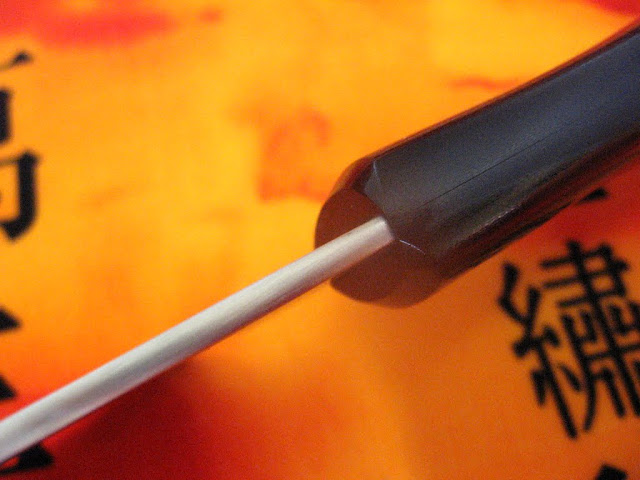

It features a tall, thin flat grind with mild convexity beginning 1/2" from the edge. Edge thickness before sharpening was .007". The blade is hand rubbed to 600 grit and the spine and heel are fully rounded for comfort. The front of the scales feature a small bevel to making cutting with a pinch grip more comfortable. Overall weight is not much, I need to get a digital scale for these again but I'd guess around 9-10 oz. total.

Blade is 2-3/16 tall at heel for lots of knuckle clearance, and edge profile is pretty flat with a mild rocking tip, French style. Handle is shaped with a palm swell, to feel comfortable in the hand.

Materials: 52100 alloy blade, G10 mortised handle with stainless and mosaic pins.

It features a tall, thin flat grind with mild convexity beginning 1/2" from the edge. Edge thickness before sharpening was .007". The blade is hand rubbed to 600 grit and the spine and heel are fully rounded for comfort. The front of the scales feature a small bevel to making cutting with a pinch grip more comfortable. Overall weight is not much, I need to get a digital scale for these again but I'd guess around 9-10 oz. total.

Blade is 2-3/16 tall at heel for lots of knuckle clearance, and edge profile is pretty flat with a mild rocking tip, French style. Handle is shaped with a palm swell, to feel comfortable in the hand.