Bill DeShivs

Knifemaker / Craftsman / Service Provider

- Joined

- Jun 6, 2000

- Messages

- 12,758

People have manually sharpened knives for well over a thousand years.

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Oh, I get it. Is that what we call the "behind the edge" width? The width of the edge shoulders?

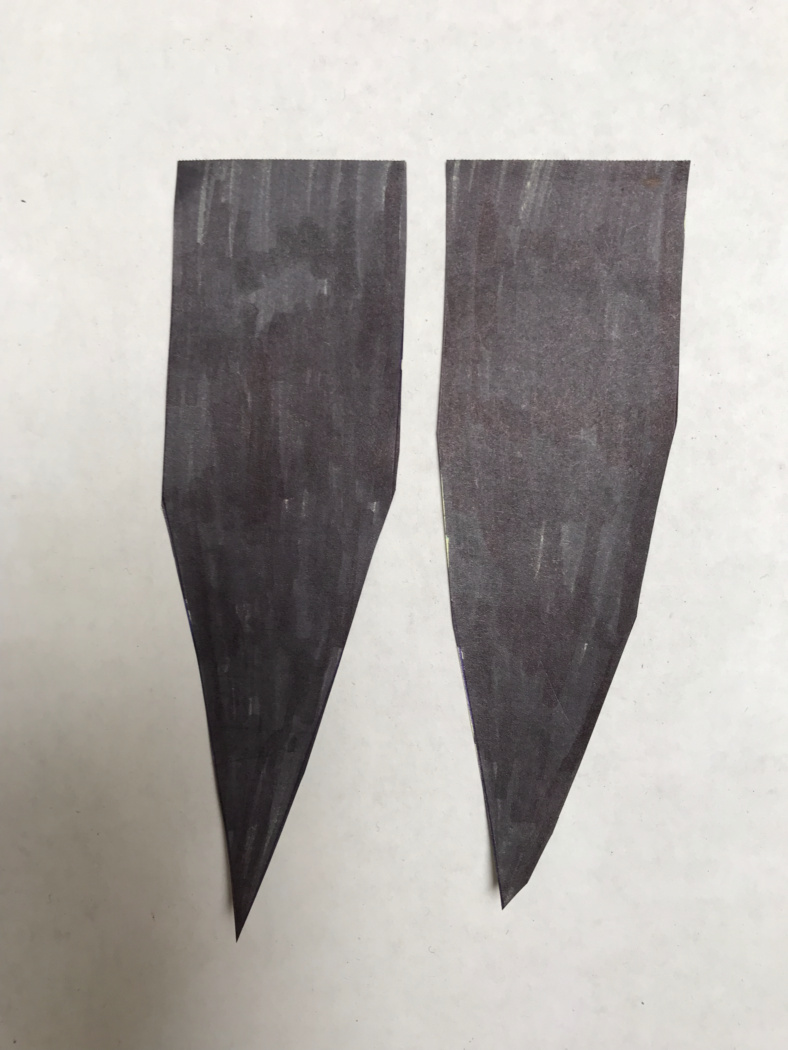

If I’m picturing your geometry correctly, you don’t have to hold 4 thousandths at the edge. You can hold 10 thou or so at the spine gap fairly easily. I don’t think people will waver 4 degrees on the same side of the knife.The photo on the right is someone freehanding a 15 dps edge. They get one side at 17 degrees and the other side at 13 degrees. And their stone gets a bit off a couple other places. The difference between the distance at the edge shoulder between a 15 and 17 degree edge is just 0.004 inches on a 0.1 inch edge height. Four thousandths of an inch. Not many people can hold a stone to that precision.

I once read a well known knifemaker address this issue.He said that symmetrical edges are ,of course,best but asymmetrical edges can still be very sharp.Here's why I think it's so difficult for someone to learn to freehand sharpen.

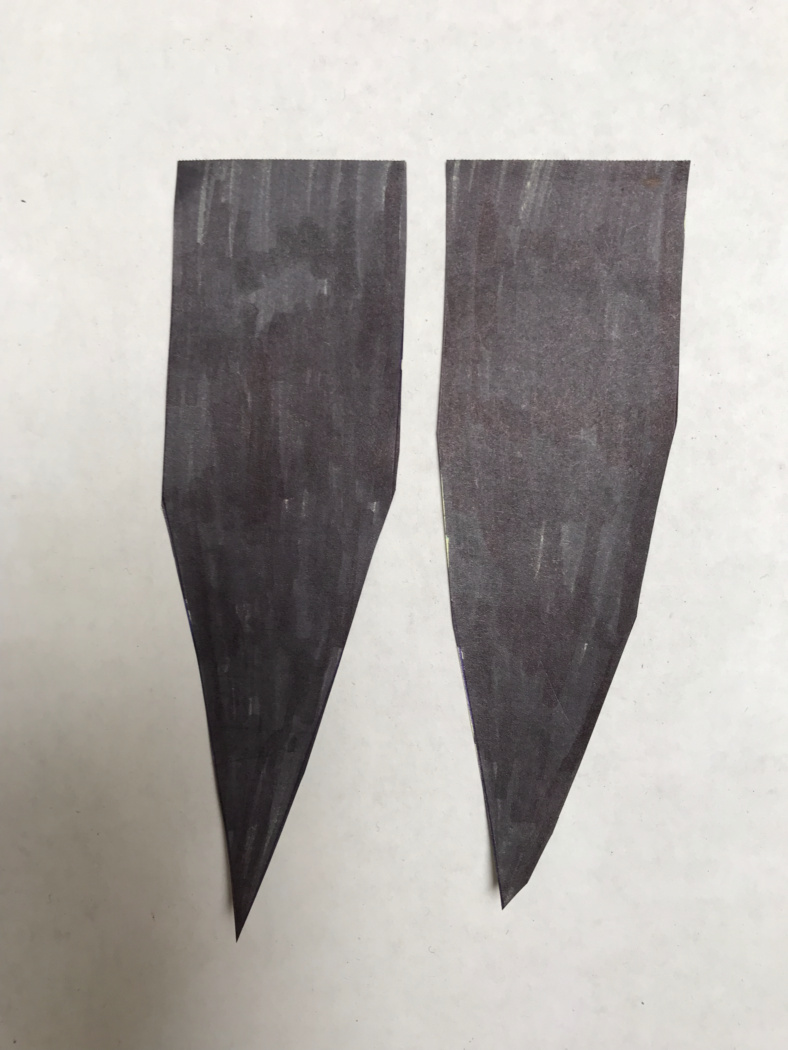

The photo on the left is a 15 dps edge done with a Wicked Edge. It's dead on.

The photo on the right is someone freehanding a 15 dps edge. They get one side at 17 degrees and the other side at 13 degrees. And their stone gets a bit off a couple other places. The difference between the distance at the edge shoulder between a 15 and 17 degree edge is just 0.004 inches on a 0.1 inch edge height. Four thousandths of an inch. Not many people can hold a stone to that precision.

The freehand edge is still sharp. Probably cuts as well. But the edge is not symmetrical. One shoulder is a bit higher than the other. The edge starts to get off center. The apex moves up into the blade a bit. Not a lot, but over time, it becomes a problem. And more metal is removed off the freehand edge. I'd expect this difference to be someone who has a lot of muscle/brain memory. A person new to sharpening will be worse that what is shown.

I just got the book and am reading it. Pretty good so far, although dated. (No known methods of testing steels of their ability to either take or hold an edge.)

The author says sharpening is not simple and the field is full of "old wives' tales and gimmickry." When he went into butcher shops, he found that only about 1 in 20 butchers could sharpen their knives properly, despite daily practice.

He also takes positions that a lot of people on this forum will not like, such as stainless steel edges lasting a lot longer than high-carbon steel edges.

And he takes down another sacred cow, saying that edges with teeth (coarse sharpening) do not last as long as a properly sharpened edge, which is smooth without teeth.

That may be. I haven't read Larrin's book yet. I'm just commenting on John Juranitch's book, because that's what this thread is about.Knife Engineering, by Dr. Larrin Thomas is a more modern book and has a lot of info on steels and edges.

That may be. I haven't read Larrin's book yet. I'm just commenting on John Juranitch's book, because that's what this thread is about.

My sharpening skills are pretty well set, but hopefully I can pick up some good tips from The Razor Edge Book of Sharpening, which was decades in the making.

This is why he recommends frequent thinning of the edge at a lower angle before final edging.Here's why I think it's so difficult for someone to learn to freehand sharpen.

The photo on the left is a 15 dps edge done with a Wicked Edge. It's dead on.

The photo on the right is someone freehanding a 15 dps edge. They get one side at 17 degrees and the other side at 13 degrees. And their stone gets a bit off a couple other places. The difference between the distance at the edge shoulder between a 15 and 17 degree edge is just 0.004 inches on a 0.1 inch edge height. Four thousandths of an inch. Not many people can hold a stone to that precision.

The freehand edge is still sharp. Probably cuts as well. But the edge is not symmetrical. One shoulder is a bit higher than the other. The edge starts to get off center. The apex moves up into the blade a bit. Not a lot, but over time, it becomes a problem. And more metal is removed off the freehand edge. I'd expect this difference to be someone who has a lot of muscle/brain memory. A person new to sharpening will be worse that what is shown.

He is right about slurry being detrimental to an apex, but he is wrong about using oil and its effects. On hard stones that don't self slurry oil might make the stone act a little finer and on some stones make them faster as well. On softer stones you might see a bump in sharpness dry.Excellent book. I stopped using oil on my stones after reading this book!

You missed the part where he says a toothy edge is inferior to a smooth, polished edge, even in the meat industry.He is right about slurry being detrimental to an apex, but he is wrong about using oil and its effects. On hard stones that don't self slurry oil might make the stone act a little finer and on some stones make them faster as well. On softer stones you might see a bump in sharpness dry.

Had he not been sharpening in a mud of grime I think the oil would have given him a better edge but maybe not toothy enough for the meat packing company.

Thats as far into the book as I got just skipping through. Probably as far as I will go.

He is right about slurry being detrimental to an apex, but he is wrong about using oil and its effects. On hard stones that don't self slurry oil might make the stone act a little finer and on some stones make them faster as well. On softer stones you might see a bump in sharpness dry.

Had he not been sharpening in a mud of grime I think the oil would have given him a better edge but maybe not toothy enough for the meat packing company.

Thats as far into the book as I got just skipping through. Probably as far as I will go.

It's interesting that he didn't polish the edges for the meat packers.You missed the part where he says a toothy edge is inferior to a smooth, polished edge, even in the meat industry.

You had the Razors Edge stones? Thoughts on the fine compared to other fine stones? Ive used a fine India and a Hard Arkansas and the jump in keenest was big between them, wonder where their hones fall in.I've had it and the stones that kind of went with it for years.. Have to think very few people *HERE* would benefit from it unless they don't mind laying their knives down on the stones and being ok with scratching the living hell out of them. IIRC he mostly concentrated on meat packing plants/knives for the book.