Josh did a beautiful reblade of a Rukus 610 in Vanax SuperClean for me, and it has been an outstanding steel. But I'd guess it would be quite different from Vancron SuperClean.

What I like about Vanax is its balance. It has excellent wear resistance -- just a bit below Elmax and well above D2 -- and excellent toughness for a stainless steel. Elmax is known as a tough powder stainless, but Vanax is quite a bit tougher, so is has better resistance to chipping and breaking than Elmax.

The other excellent feature is its fine grain, which takes an incredible edge. It's also way more stain resistant than other stainless steels.

Living in the rainforest and walking trails with my dog everyday, I often use Vanax for chopping free-hanging branches. That seems like a simple task, but the lateral forces can be very high, especially when cutting through wood where the grain pattern changes and the blade has a lot of momentum. This activity has destroyed the edge -- even the blades -- of many lesser steels. Vanax has stood up to it all. The first steel I've found to do so.

Phil Wilson calls this twisting toughness, or torque. It's not a quality found on data sheets, and all high-vanadium steels will have poor torque. When you combine twisting torque with impact, not many thin edges will avoid damage. But Vanax is awesome. After lots of chopping, it has no damage. It holds an edge really well (like good S30V), is easy to sharpen, takes a super keen edge, is virtually stain free and has enough toughness to generate excellent edge stability (resistance to both denting/rolling and chipping/breaking). I also believe that the super stain-resistance keeps the edge apex from corroding, especially in wet environments (rainforest) or where you inadvertently leave small bits of whatever you were cutting on the edge. The Vanax edge doesn't care. What's not to like.

Vancron is much different.

Vancron is a high-vanadium steel run much harder than Vanax. (It has 10 percent Vanadium, as much as the rest of the alloys combined, including carbon.) Vanax will top out at 60-61 Rc. Vancron can be run up to 68 Rc. Voestalpine, the parent company of Uddeholm, puts Vancron's abrasive wear at 70 percent, compared to D2 at 55 percent. It rates it considerably tougher than D2, but considerably less tough than Vanax.

I've never used Vancron, but it should be superior on wear resistance, but weaker on toughness than Vanax. So it would be a more dedicated blade and Vanax more balanced.

When I lost my Vanax Rukus, I was totally upset, because it was the best EDC I've ever had. There were three cases where I had to cut rope tie-downs on heavy equipment I was delivering for repair. The Vanax blade was so sharp and such an aggressive cutter that the rope just fell away, leaving the mechanics talking excitedly about my knife, not the equipment. It's that good.

Fortunately, I found the lost Vanax Rukus hanging from a tool belt that had snagged the pocket clip.

Josh did excellent work on that regrind.

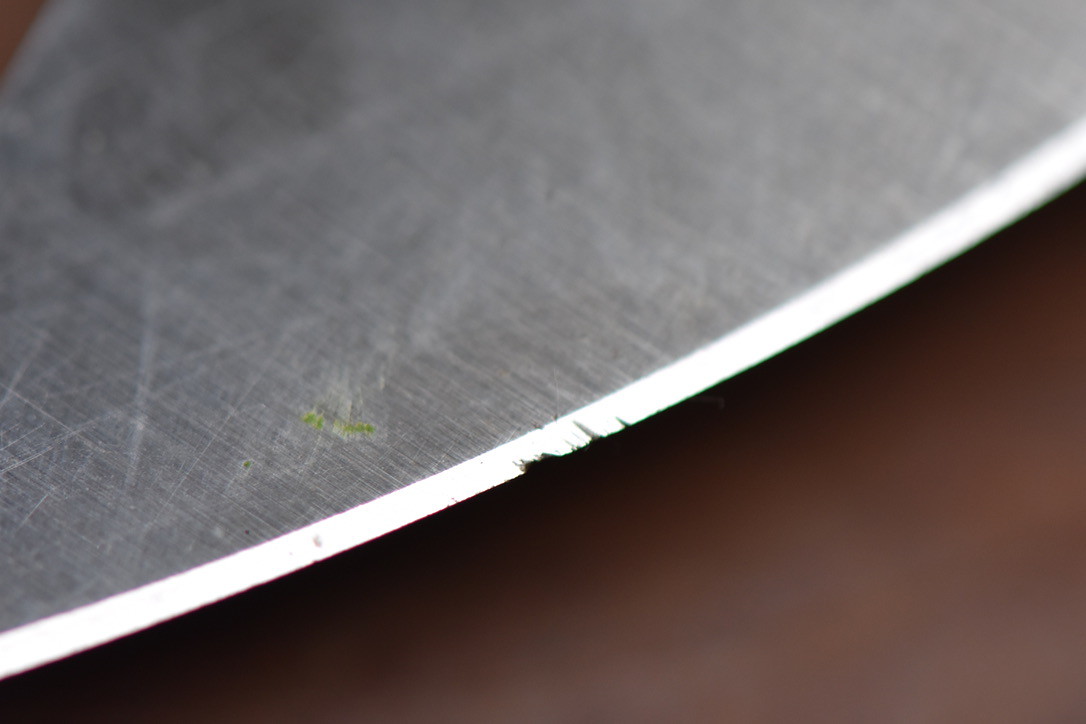

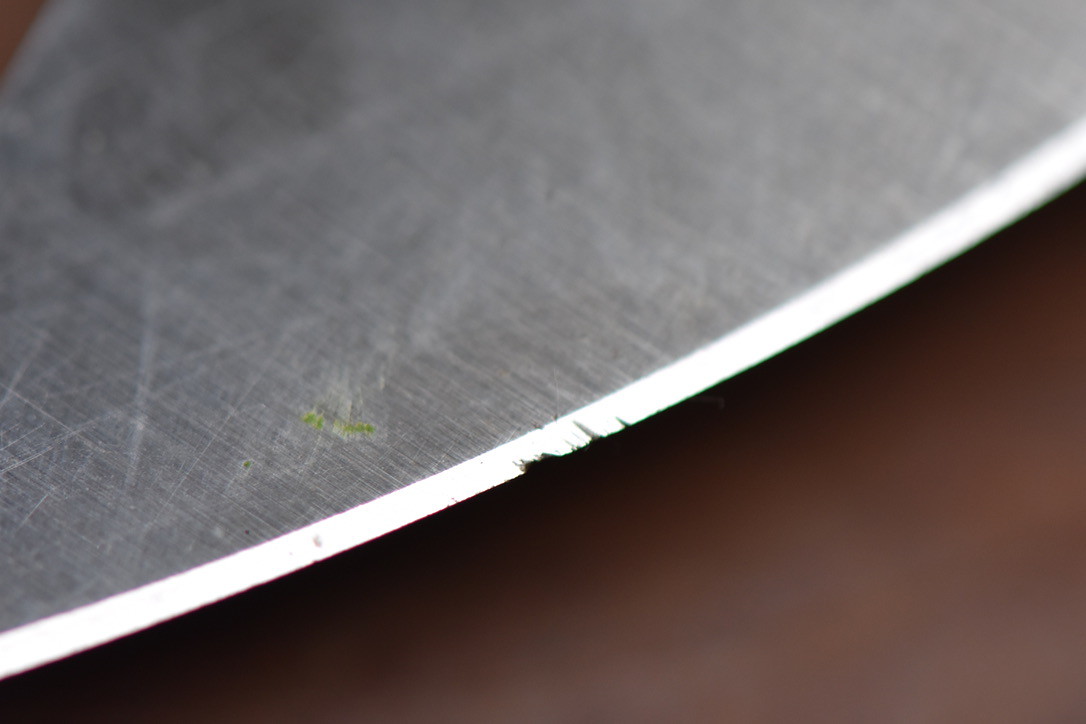

Here's some chopping damage done to an extremely tough, low-alloy steel. It shows how powerful the impact torque can be on an edge. Vanax has suffered no damage at all from lots of chopping.

What I like about Vanax is its balance. It has excellent wear resistance -- just a bit below Elmax and well above D2 -- and excellent toughness for a stainless steel. Elmax is known as a tough powder stainless, but Vanax is quite a bit tougher, so is has better resistance to chipping and breaking than Elmax.

The other excellent feature is its fine grain, which takes an incredible edge. It's also way more stain resistant than other stainless steels.

Living in the rainforest and walking trails with my dog everyday, I often use Vanax for chopping free-hanging branches. That seems like a simple task, but the lateral forces can be very high, especially when cutting through wood where the grain pattern changes and the blade has a lot of momentum. This activity has destroyed the edge -- even the blades -- of many lesser steels. Vanax has stood up to it all. The first steel I've found to do so.

Phil Wilson calls this twisting toughness, or torque. It's not a quality found on data sheets, and all high-vanadium steels will have poor torque. When you combine twisting torque with impact, not many thin edges will avoid damage. But Vanax is awesome. After lots of chopping, it has no damage. It holds an edge really well (like good S30V), is easy to sharpen, takes a super keen edge, is virtually stain free and has enough toughness to generate excellent edge stability (resistance to both denting/rolling and chipping/breaking). I also believe that the super stain-resistance keeps the edge apex from corroding, especially in wet environments (rainforest) or where you inadvertently leave small bits of whatever you were cutting on the edge. The Vanax edge doesn't care. What's not to like.

Vancron is much different.

Vancron is a high-vanadium steel run much harder than Vanax. (It has 10 percent Vanadium, as much as the rest of the alloys combined, including carbon.) Vanax will top out at 60-61 Rc. Vancron can be run up to 68 Rc. Voestalpine, the parent company of Uddeholm, puts Vancron's abrasive wear at 70 percent, compared to D2 at 55 percent. It rates it considerably tougher than D2, but considerably less tough than Vanax.

I've never used Vancron, but it should be superior on wear resistance, but weaker on toughness than Vanax. So it would be a more dedicated blade and Vanax more balanced.

When I lost my Vanax Rukus, I was totally upset, because it was the best EDC I've ever had. There were three cases where I had to cut rope tie-downs on heavy equipment I was delivering for repair. The Vanax blade was so sharp and such an aggressive cutter that the rope just fell away, leaving the mechanics talking excitedly about my knife, not the equipment. It's that good.

Fortunately, I found the lost Vanax Rukus hanging from a tool belt that had snagged the pocket clip.

Josh did excellent work on that regrind.

Here's some chopping damage done to an extremely tough, low-alloy steel. It shows how powerful the impact torque can be on an edge. Vanax has suffered no damage at all from lots of chopping.