I don't recall the alloy, as it was probably a one-off. The number of various ti alloys that are or were mass-produced and have an ASTM grade is quite low, but there are many oddball ti alloys that were made in small batches over the years, mostly several decades ago. While steel metallurgy has continued to advance, titanium metallurgical advancements have been stalling, and sort of repeating themselves for quite some time now.

The hardest ones I tested that weren't roached-out were upper 50s, and beyond that I was getting negative results as a blade. Generally speaking, with titanium alloys it's the crystalline phase and microstructure that matters, a lot more than hardness. "Alpha Prime"

Titanium martensite doesn't want to yield, and it takes a lot to break it. It's flexible and tough, but isn't malleable and doesn't want to gall (edge doesn't get easily smooshed with use, which has always been the problem with ti) which helps immensely with edge-holding.

The hardness and other characteristics after creating "Alpha Prime" titanium martensite is going to be largely determined by the alloying elements, and trying to get it to read higher on a Rockwell hardness test isn't necessarily going to increase blade performance (though of course some things do follow along with hardness). The basic main point is that in this phase, it doesn't take a set or yield, therefore the fine-grained edge is going to go through whatever's being cut without issues, provided it's not highly abrasive. That's the mechanism by which a hardened ti alloy blade works.

The general consensus is that as a knife it functions a lot like a nice basic high carbon steel.

If you guys want to see a nice chef knife, made out of actual titanium alloy, here is a recent one made by

BladeMan

BladeMan

. I only heat treated it, he did everything else:

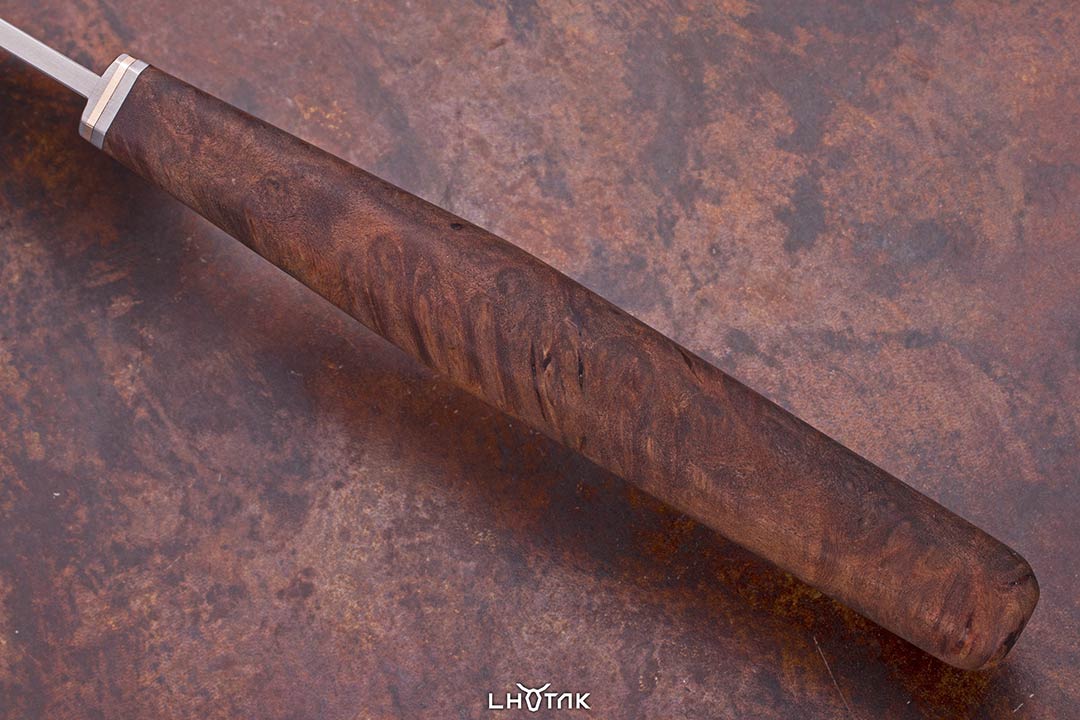

Just finished this Kitchen Knife Prototype, made from heat treated ATI425 Titanium. HT was done by @Mecha. Handle is stab. Redwood burl and some Titanium and Bronze. OAL is 11.7" Blade is 7" long and .110" thick Weight is 3.24 oz

www.bladeforums.com