With any and every stone brand or type - doesn't matter who makes it or where it's from, I would recommend getting into the habit of using your angle cube to readjust your angle each and every time you swap stones. For consistency, measure it on the same side of your blade, in the same spot on the stone and blade.

Even if your stones are 100% the same thickness when new (which hardly any stones are), invariably they will start to change in thickness with use. Your coarse stones (doing the bulk of the work on new knives and bevel setting) will wear down a little faster than the rest, so they will narrow out with time. It's also a good habit to use an angle cube every time you change a stone, so you can mix and match stone types, brands and sizes while you experiment and sharpen.

The Geometry mentioned above was from my explanation on bevel length for 1 degree angle difference, it's not related to this thread because we are talking here about changes in angle on the same bevel side, between stone ends. That could effectively make a difference, depending on some factors.

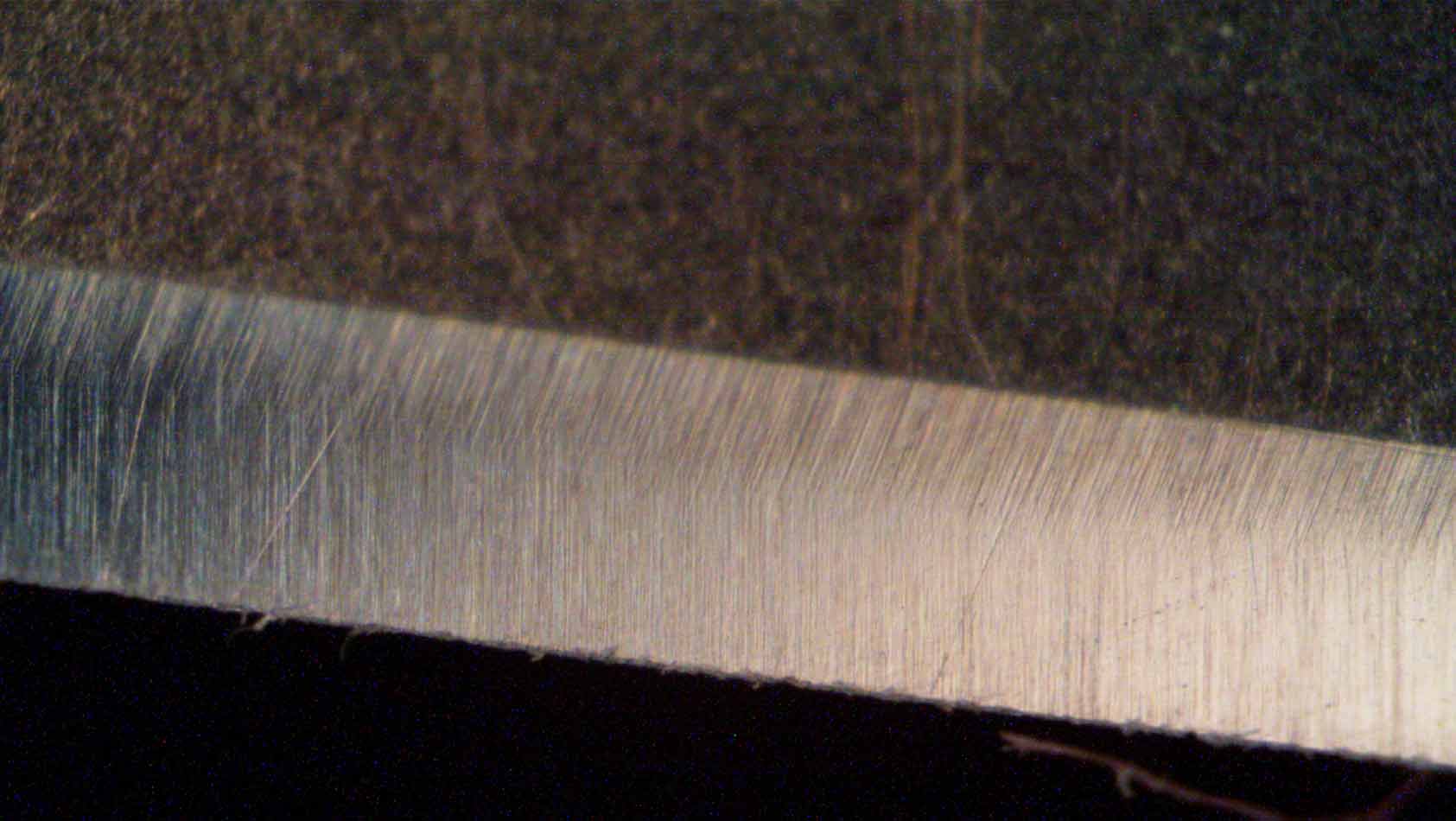

We also spoke about geometry in another thread that was relating to very slight dishing of stones, but that discussion relates to very slight variations from one end to the other on the same stone. Depending on the stone variations, your sharpening pressure and time spent on each stone will have much more effect on your bevels than tiny inconsistencies. That being said, if you have 0.6mm difference in stone thickness from one end to the other on the same stone, it could possibly make 1-2 degrees difference in contact angle on your blade (depending on the arm length from your stone rod pivot point to the contact point on your knife.)

The Venev stones are phenomenal stones for the money, and they will give you excellent edges. If the tiny change in thickness from one side to the other of your 1200/1500 bothers you or makes a significant difference, then it's very quick and easy to even it out with some silicon carbide. I would not do too much if I were you, because you'll just be wasting away good stone surface, but it's easily doable if you need to. Just be careful not to do too much.