-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VG10W experience?

- Thread starter Skidoosh

- Start date

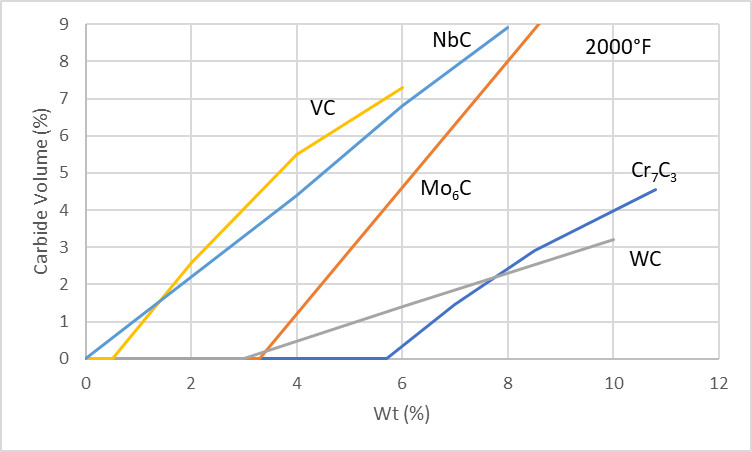

No experience, however, I'm not sure the 0.4% in additional Tungsten (that's where the "W" comes in) would contribute to a significant increase in carbide volume to have a noticeable boost in performance.

Don't get me wrong, any incremental performance, I'd still take. Would still need to be optimized by the maker (HT, grind thickness, etc.). Maybe, the additional W is there to help with HTing?

Don't get me wrong, any incremental performance, I'd still take. Would still need to be optimized by the maker (HT, grind thickness, etc.). Maybe, the additional W is there to help with HTing?

gazz98

Gold Member

- Joined

- Sep 3, 2008

- Messages

- 5,390

I've heard of it but never used it. The Fallkniven NL5L Idun knife uses it. Copy and pasted from the Fallkniven website.

The laminated blade is forged with an edge of VG10W steel to which we have added tungsten (W). In general, the addition of tungsten means that the edge becomes substantially more solid and keeps the sharpness better, at least that is what our own tests have showed. And the sides are made of a tough, all-stainless 420J2 steel. This excellent combination of metals brings together all conceivable and desirable knife properties including resilience, resistance to torque and edge-durability all in a single blade.

The laminated blade is forged with an edge of VG10W steel to which we have added tungsten (W). In general, the addition of tungsten means that the edge becomes substantially more solid and keeps the sharpness better, at least that is what our own tests have showed. And the sides are made of a tough, all-stainless 420J2 steel. This excellent combination of metals brings together all conceivable and desirable knife properties including resilience, resistance to torque and edge-durability all in a single blade.

- Joined

- Dec 5, 2018

- Messages

- 1,437

From ZKnives:

Generally speaking that is a welcomed addition, because it is a good carbide former, improves hadrenability [sic] and all that. The only thing is it's just 0.40% of it, and given Tungsten's very high molar mass, 0.40% translates into very few Tungsten atoms to influence alloy properties, e.g. the same amount of Vanadium would have thrice the amount of the atoms. Anyway, it's there and it's helping, wot' [sic] make things worse. I suspect you will be very hard pressed to tell the difference in two identical knives, but still, it's an upgrade.

Generally speaking that is a welcomed addition, because it is a good carbide former, improves hadrenability [sic] and all that. The only thing is it's just 0.40% of it, and given Tungsten's very high molar mass, 0.40% translates into very few Tungsten atoms to influence alloy properties, e.g. the same amount of Vanadium would have thrice the amount of the atoms. Anyway, it's there and it's helping, wot' [sic] make things worse. I suspect you will be very hard pressed to tell the difference in two identical knives, but still, it's an upgrade.

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

Tungsten is not a strong carbide forming element in steels. Especially in the presence of chromium.I have not seen much written on VG10W. Anyone have any real world experience or thoughts on it?

That's why when they make tungsten carbide metals they synthesize the Tungsten carbide separately and put it in a binder of cobalt.

Should also be noted that pure tungsten is not the same as tungsten carbide, pure tungsten is significantly softer and less wear resistant.

Tungsten being a weak carbide former in steel means it is less likely to make its own carbides.

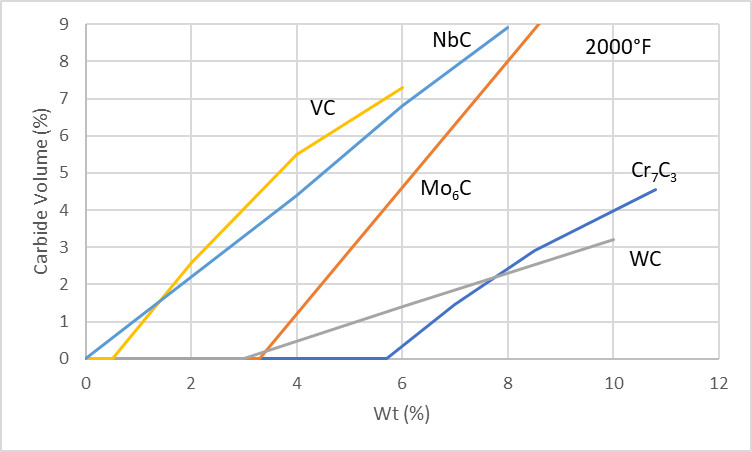

We need to remember carbides are a mix of carbon and metallic elements and there is a hierarchy of what carbides form within the steel.

So with tungsten being weak at forming its own carbides we don't get the exciting, hard Tungsten carbides (still softer than Vanadium Carbide) in these kinds of steels.

Tungsten behaves similar to Molybdenum in steels. (Molybdenum is also a weak former)

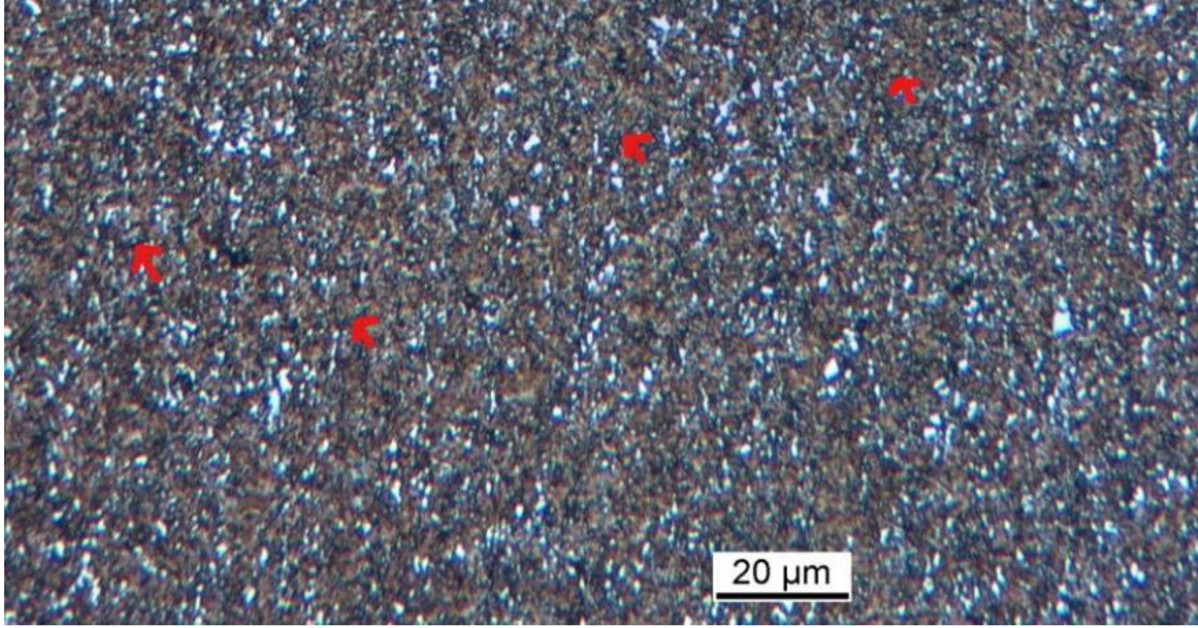

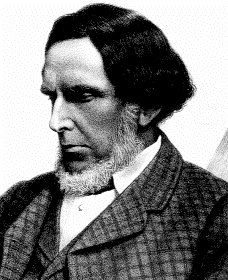

If you look at 154cm/RWL-34/CPM 154/ ATS-34 with 4% wt Molybdenum,

One notices there aren't any super hard molybdenum monocarbides blasting the wear resistance in CPM 154 for the same reasons we don't get tungsten carbide in VG10W or even Maxamet for that matter.

It's more complicated than "Tungsten make mo' Betta" yet it's also a lot more beautiful in it's complexity.

Even if they added 4% W to VG10 it's not going to increase the wear resistance due to harder carbides.

Again, Carbides are a mix of carbon and metallic elements.

The tungsten is simply overpowered by the other elements dominating what carbides are being formed.

Long story short, VG10W is nothing special and misleading.

Just captures the imagination of casual folks because Tungsten is known as a "hard element" and has "cool factor" and name recognition but, for the most part, folks don't understand the differences between the elements and carbides. It is not intuitive to understand the complex hierarchies of what carbides are being formed.

Should also note that raw tungsten atoms "hanging out" in solution with iron are not going to blast performance either.

T1 HSS steel has 18 % tungsten , T15 HSS has 12.5 % tungsten , why ?Tungsten is not a strong carbide forming element in steels. Especially in the presence of chromium.

That's why when they make tungsten carbide metals they synthesize the Tungsten carbide separately and put it in a binder of cobalt.

Should also be noted that pure tungsten is not the same as tungsten carbide, pure tungsten is significantly softer and less wear resistant.

Tungsten being a weak carbide former in steel means it is less likely to make its own carbides.

We need to remember carbides are a mix of carbon and metallic elements and there is a hierarchy of what carbides form within the steel.

So with tungsten being weak at forming its own carbides we don't get the exciting, hard Tungsten carbides (still softer than Vanadium Carbide) in these kinds of steels.

Tungsten behaves similar to Molybdenum in steels. (Molybdenum is also a weak former)

If you look at 154cm/RWL-34/CPM 154/ ATS-34 with 4% wt Molybdenum,

One notices there aren't any super hard molybdenum monocarbides blasting the wear resistance in CPM 154 for the same reasons we don't get tungsten carbide in VG10W or even Maxamet for that matter.

It's more complicated than "Tungsten make mo' Betta" yet it's also a lot more beautiful in it's complexity.

Even if they added 4% W to VG10 it's not going to increase the wear resistance due to harder carbides.

Again, Carbides are a mix of carbon and metallic elements.

The tungsten is simply overpowered by the other elements dominating what carbides are being formed.

Long story short, VG10W is nothing special and misleading.

Just captures the imagination of casual folks because Tungsten is known as a "hard element" and has "cool factor" and name recognition but, for the most part, folks don't understand the differences between the elements and carbides. It is not intuitive to understand the complex hierarchies of what carbides are being formed.

Should also note that raw tungsten atoms "hanging out" in solution with iron are not going to blast performance either.

The tungsten series include the T1 to T15 class alloys. Tungsten is a good carbide former that prevents grain growth, enhances toughness and increases red hardness and high temperature strength. Tungsten is used in hot forming tool steels and high-speed steels.

Data from Takefu ....................are they are liars ??

VG10W is made by adding tungsten (W) to VG10 to further enhance the excellent properties of VG10.

W precipitates and disperses hard, fine carbides, which contribute to improved wear resistance and ease of sharpening. Also, the addition of W further improves the hardenability of the material. It is therefore easy to obtain superior hardness by quenching, which does not degrade even after high temperature tempering.

Compared to VG10, VG10W has 20% higher durability/strength and 25% higher cutting performance, while maintaining the same corrosion resistance.

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

For the same reason they use Molybdenum in HSS.T1 HSS steel has 18 % tungsten , T15 HSS has 12.5 % tungsten , why ?

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

Data from Takefu ....................are they are liars ??

"0.40% weight Tungsten"

Are they are liars ?"0.40% weight Tungsten"

Compared to VG10, VG10W has 20% higher durability/strength and 25% higher cutting performance, while maintaining the same corrosion resistance.

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

Are they are liars ?

Compared to VG10, VG10W has 20% higher durability/strength and 25% higher cutting performance, while maintaining the same corrosion resistance.

there is some great writing about tungsten steels here, by

Larrin

Larrin

he explains the nuance better than anyone, & you should buy his book if you're in the rabbit hole ; )

knifesteelnerds.com

knifesteelnerds.com

he explains the nuance better than anyone, & you should buy his book if you're in the rabbit hole ; )

Toughness Improvement of High Carbon Tungsten Steel 1.2562 - Knife Steel Nerds

Previous toughness measurements of the tungsten-alloyed forging steel 1.2562 showed low values. Knifemaker Marco Guldimann contacted me about improving it.

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

N

Natlek

No Tungsten carbide here either, even more W than VG10W too.

[Bohler M398 Data Sheet]

As for the carbides in T1 and T15 you get these, MC and M6C

[Sidi Lian 2015]

Diagrams on carbides found in HSS, W goes towards M6C, softer carbide than WC

M6C labeled as "Iron-Tungsten-Molybdenum Carbide in HSS" it's softer than WC

No WC phases in HSS, even in T1 with 18%wt W

Source for diagrams, details on why WC doesn't form in HSS also explained on page 605

Was also explained in "Knife Engineering"

Carbide types in steels and hardnesses

Why no WC in Cr air hardening steels

Some explanation on "M6C" and table shows no WC in T1 18%wt W.

No Tungsten carbide here either, even more W than VG10W too.

[Bohler M398 Data Sheet]

As for the carbides in T1 and T15 you get these, MC and M6C

[Sidi Lian 2015]

Diagrams on carbides found in HSS, W goes towards M6C, softer carbide than WC

M6C labeled as "Iron-Tungsten-Molybdenum Carbide in HSS" it's softer than WC

No WC phases in HSS, even in T1 with 18%wt W

Source for diagrams, details on why WC doesn't form in HSS also explained on page 605

Was also explained in "Knife Engineering"

Carbide types in steels and hardnesses

Why no WC in Cr air hardening steels

Some explanation on "M6C" and table shows no WC in T1 18%wt W.

DeadboxHero

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 22, 2014

- Messages

- 5,463

N

Natlek

"Why Tungsten?"

Ask Robert F. Mushet

en.m.wikipedia.org

en.m.wikipedia.org

Maybe ya missed this article, good in depth read.

knifesteelnerds.com

knifesteelnerds.com

.

Here's another article to read about carbides

(One of my favorite KSN articles)

knifesteelnerds.com

knifesteelnerds.com

Some nuisances about what W is doing for carbides in HSS.

great article about HSS with some details about W and Mo in high speed steels like T1 and T15

knifesteelnerds.com

knifesteelnerds.com

www.bladeforums.com

www.bladeforums.com

Fun thread where we geek out on carbides, perhaps move the discussion there?

"Why Tungsten?"

Ask Robert F. Mushet

Robert Forester Mushet - Wikipedia

Maybe ya missed this article, good in depth read.

The History of the First Tool Steel - Knife Steel Nerds

The steel largely recognized as being the “first tool steel” was developed by Robert Forester Mushet, a British metallurgist, in 1868 [1]. Mushet improved the Bessemer steelmaking process through the addition of a small amount of manganese [1]. Later Mushet was experimenting with various...

.

Here's another article to read about carbides

(One of my favorite KSN articles)

Carbide Types in Knife Steels - Knife Steel Nerds

A description of the major carbide types in steels, how they form, why they are there, and how carbides contribute to different properties of steel.

Some nuisances about what W is doing for carbides in HSS.

great article about HSS with some details about W and Mo in high speed steels like T1 and T15

Super Hard (70 Rc) High Speed Steels - Maxamet, Rex 121, and More Explained - Knife Steel Nerds

How did metallurgists design steels that reach 70 Rockwell C? What kind of properties do these steels achieve? Do they have any toughness at all?

Carbide Hardness Chart

I made a Carbide Hardness Chart for quick reference, useful for folks that are curious about which steels would be more wear resistant than others and what stones to use. I thought it would be fun for folks that are really geeked out to be on the same page and also a fun thread to discuss...

www.bladeforums.com

www.bladeforums.com

Fun thread where we geek out on carbides, perhaps move the discussion there?