What about Shun VG-10? In appendix2 you rated it at 12 degrees!SHUN VG-MAX

SHUN knives almost always come chipped to a sharpener, and I repeatedly saw its apex chipping during grinding on #160-200, when we ground them at <= 14 dps. We grind edge-leading. So we decided to stick with the manufacturer's recommendation of 16 dps. At 16 dps SHUN does not chip, well at least not during grinding.

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What edge angle is good for supersteels

- Thread starter wootzblade

- Start date

- Joined

- Feb 24, 2014

- Messages

- 240

VG-10 performs at 12 dps very well in slicing, as do the majority of quality knife steels.

Last edited:

- Joined

- Feb 24, 2014

- Messages

- 240

Both have chipping problem, but they are very different steels, and the VG-MAX has chipping problem at its maximum, while the VG-10 shows far less chipping, even at low angles. Do not lower the VG-10 edge angle past 12 dps, and it will perform alright.

Let me try to list my first bunch of questions which were result of reading both Dr. Vadim Kraichuk book and this thread together:

1. There the term positive/negative burr came from? Is it your lab discovery or it was around for a while?

2. Based on the burr management, can we say what we should try to avoid steels which are too soft to form negative burr?

3. What is the best steel (group of steels) which are better for kitchen knives from practical point for a) scary sharp edge b) working sharp edge? What I mean is the ratio of sharpening efforts to knife keeping its edge.

4. Can I assume that VG-10 holds its edge better that VG-MAX since we can apply 12 DPS on it and thus is more practical?

5. Are there any illustrations photos of positive VS negative burr edges?

6. Should I assume that using a ceramic rod even high grit one will generate a burr so my plan on keeping knives sharp by maintaining them with frequent ceramic rod honing is fruitless?

7. All your shop sharpening is made on machines. Is there any specific alternation of de-burring in freehand sharpening?

1. There the term positive/negative burr came from? Is it your lab discovery or it was around for a while?

2. Based on the burr management, can we say what we should try to avoid steels which are too soft to form negative burr?

3. What is the best steel (group of steels) which are better for kitchen knives from practical point for a) scary sharp edge b) working sharp edge? What I mean is the ratio of sharpening efforts to knife keeping its edge.

4. Can I assume that VG-10 holds its edge better that VG-MAX since we can apply 12 DPS on it and thus is more practical?

5. Are there any illustrations photos of positive VS negative burr edges?

6. Should I assume that using a ceramic rod even high grit one will generate a burr so my plan on keeping knives sharp by maintaining them with frequent ceramic rod honing is fruitless?

7. All your shop sharpening is made on machines. Is there any specific alternation of de-burring in freehand sharpening?

The term negative burr appears in other literature, some with citations to "Gillespie L. The battle of the burr: new strategies and new tricks. Manufacturing Engineering 1996"

Ceramic rod honing is certainly not fruitless, though I would not use it on hard, brittle steel like Aogami Super and the edge quality may or may not be up to a particular standard. From scienceofsharp I do not see indication that a ceramic rod produces more burr than other methods (@Todd S may correct me) but rather that the ceramic rod edge is neither as sharp nor as clean as the Olfa factory edge.

scienceofsharp: Olfa factory edge

scienceofsharp: Olfa blade after dulling, then ceramic rod honing

Ceramic rod honing is certainly not fruitless, though I would not use it on hard, brittle steel like Aogami Super and the edge quality may or may not be up to a particular standard. From scienceofsharp I do not see indication that a ceramic rod produces more burr than other methods (@Todd S may correct me) but rather that the ceramic rod edge is neither as sharp nor as clean as the Olfa factory edge.

scienceofsharp: Olfa factory edge

scienceofsharp: Olfa blade after dulling, then ceramic rod honing

David Martin

Moderator

- Joined

- Apr 7, 2008

- Messages

- 19,520

Nice photos. A big difference. I use 12-13* with most steels and this seems to work. Thanks, DM

- Joined

- Feb 24, 2014

- Messages

- 240

Let me try to list my first bunch of questions which were result of reading both Dr. Vadim Kraichuk book and this thread together:

1. There the term positive/negative burr came from? Is it your lab discovery or it was around for a while?

2. Based on the burr management, can we say what we should try to avoid steels which are too soft to form negative burr?

3. What is the best steel (group of steels) which are better for kitchen knives from practical point for a) scary sharp edge b) working sharp edge? What I mean is the ratio of sharpening efforts to knife keeping its edge.

4. Can I assume that VG-10 holds its edge better that VG-MAX since we can apply 12 DPS on it and thus is more practical?

5. Are there any illustrations photos of positive VS negative burr edges?

6. Should I assume that using a ceramic rod even high grit one will generate a burr so my plan on keeping knives sharp by maintaining them with frequent ceramic rod honing is fruitless?

7. All your shop sharpening is made on machines. Is there any specific alternation of de-burring in freehand sharpening?

1. There the term positive/negative burr came from? Is it your lab discovery or it was around for a while?

These are specialist literature terms known for at least 25 years. You could tell this by the Burr Formation Scheme on the page 18 of the Knife Deburring book, and the referenced literature.

2. Based on the burr management, can we say what we should try to avoid steels which are too soft to form negative burr?

I always recommend to start learning sharpening on the higher-end knives that produce the negative or near negative burr - the whole sharpening and deburring process goes at the edge angle, so you can train the muscle memory and get great satisfaction in the high sharpness you get, as long as you maintain the same angle from start to finish. Positive burr requires more skills to deburr cleanly.

Other than that, it depends on the steel properties that you are after - positive vs negative burr form on steels of polar qualities, as explained on the pages 16-19 of the Knife Deburring book.

3. What is the best steel (group of steels) which are better for kitchen knives from practical point for a) scary sharp edge b) working sharp edge? What I mean is the ratio of sharpening efforts to knife keeping its edge.

Together with the Australian Knife Magazine, we've started the project of Ranking kitchen & butcher knife brands by CATRA testing.

Currently in the process of collecting donations for the first round of tests.

This is going to be the most unbiased and objective ranking of kitchen knives.

http://knifegrinders.com.au/brand-ranking.htm

4. Can I assume that VG-10 holds its edge better that VG-MAX since we can apply 12 DPS on it and thus is more practical?

No, why? From that you can only assume that VG-10 is less brittle than the VG-MAX, but this is not related to the edge retention, at least not directly.

True that using VG-10 steel would be more "practical" in cutting dense stuff as compared to the VG-MAX.

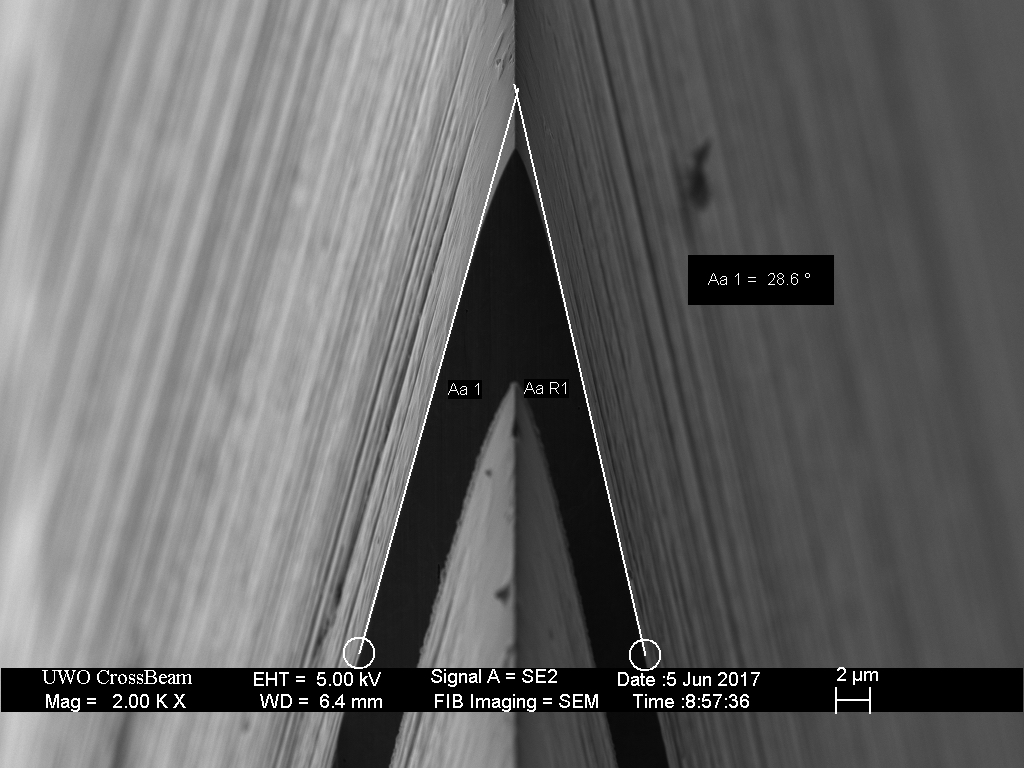

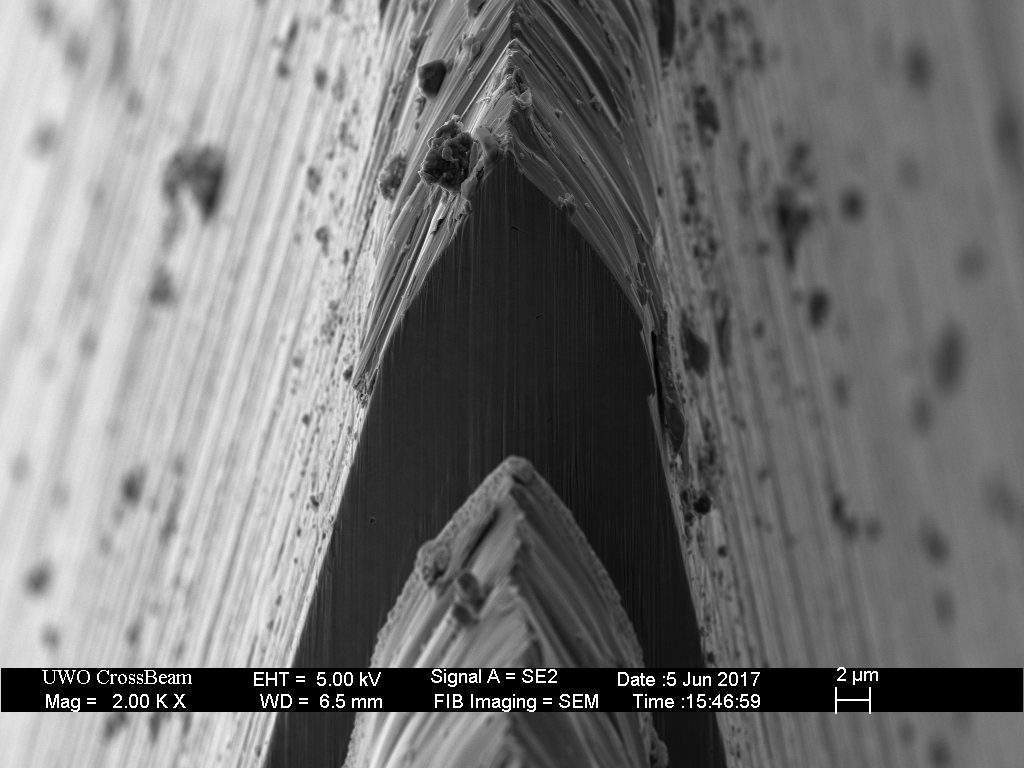

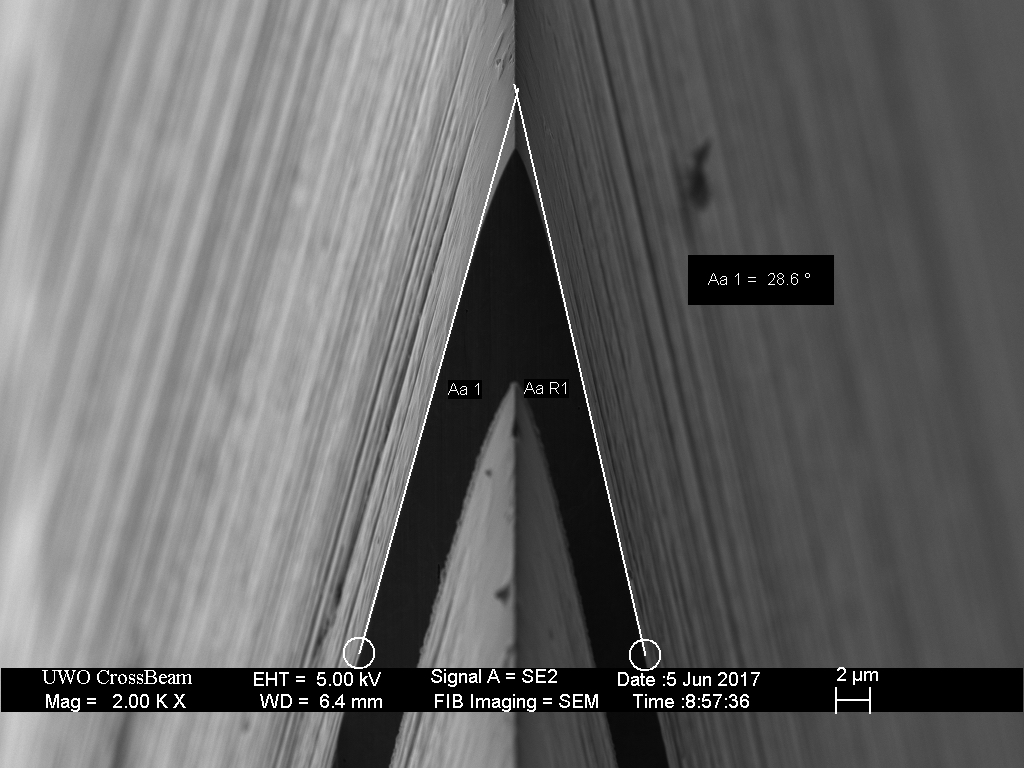

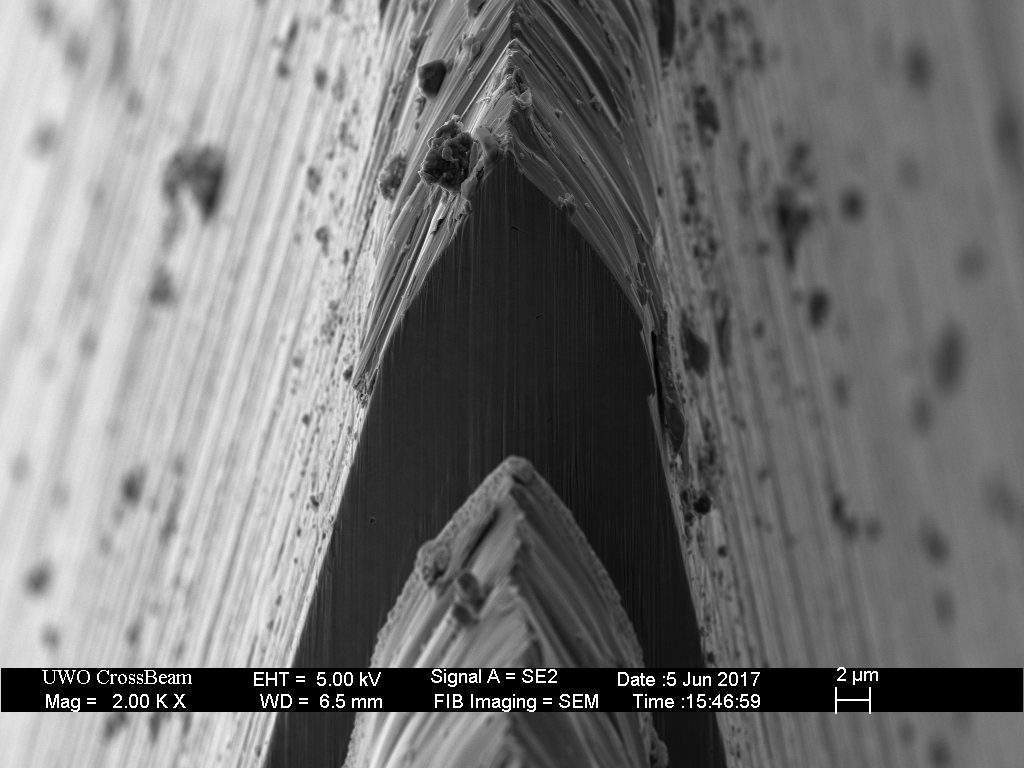

5. Are there any illustrations photos of positive VS negative burr edges?

The Negative burr can be seen only by SEM cross-section through the root of the burr - I added an image to the latest edition of the Knife Deburring book.

6. Should I assume that using a ceramic rod even high grit one will generate a burr so my plan on keeping knives sharp by maintaining them with frequent ceramic rod honing is fruitless?

Ceramic rod will "generate a burr", but I don't see how this makes use of it "fruitless"? - except for the polished steeling rod and plain leather stropping, any form of sharpening will "generate a burr".

7. All your shop sharpening is made on machines. Is there any specific alternation of de-burring in freehand sharpening?

Even though we sharpen chiefly on wheels in our workshop, the Knife Deburring book is not about the Tormek or paper wheels - it is about the burr and its removal in general.

Tormek etc are detailed only to illustrate our sharpening and deburring practices - you adapt them to the sharpening equipment you have.

Last edited:

Vadim,

Thank you very much for thorough answers! It took you awhile to answer but it was worth waiting!!! Few follow ups:

I can not remember immediately but somewhere in your charts you did not recommend VG-MAX for 12 DPS. That what the reason for my question.

If I made my knife sharp and next day before use I used abrasive rod it should ruin the burrlessness of the knife. Is it true?

Thank you in advance,

Thank you very much for thorough answers! It took you awhile to answer but it was worth waiting!!! Few follow ups:

4. Can I assume that VG-10 holds its edge better that VG-MAX since we can apply 12 DPS on it and thus is more practical?

No, why? From that you can only assume that VG-10 is less brittle than the VG-MAX, but this is not related to the edge retention, at least not directly.

True that using VG-10 steel would be more "practical" in cutting dense stuff as compared to the VG-MAX.

I can not remember immediately but somewhere in your charts you did not recommend VG-MAX for 12 DPS. That what the reason for my question.

6. Should I assume that using a ceramic rod even high grit one will generate a burr so my plan on keeping knives sharp by maintaining them with frequent ceramic rod honing is fruitless?

Ceramic rod will "generate a burr", but I don't see how this makes use of it "fruitless"? - except for the polished steeling rod and plain leather stropping, any form of sharpening will "generate a burr".

If I made my knife sharp and next day before use I used abrasive rod it should ruin the burrlessness of the knife. Is it true?

Thank you in advance,

Last edited:

- Joined

- Oct 11, 2014

- Messages

- 1,040

What edge angle is good for supersteels - Part 1

andWhat edge angle is good for supersteels - Part 2: Data, discussion and conclusions

http://knifegrinders.com.au/16SET.htm

Thank you for this study, I appreciate your meat cutters research context and your knife business history. Thank you for publishing. Particle metallurgy no doubt was a necessary material science improvement to achieve the two "super steel" design goals. I was glad your test knives were previously tested as production meat cutting knives, nice and thin relative to some pry bars with a cutting edge.

Revisiting Bohler's m390 goals, I discovered I was in error, thinking it was produced as a surgical steel. It has become my favorite steel as Benchmade 710 and 810 knives, and 20cv in 940. I do plan on thinning all three based on handle strength. I'm adding your book to my never shrinking, only growing book list. Thank you... I think

Aside #1 For studying data and explanations, a visit to the library for "Beautiful Evidence" by Tufte would be a good primer on producing and understanding evidence (practicing smelling a rat, most commonly seen as preconceptions: often evidence of intent, bias, scholarship, a discernible combination thereof, etc).

Aside#2

I just learned that Ford's Model T motor block had a high vanadium steel formula, credited with the block's servicability almost 100 years down the road. It would be interesting to see some SEM's and that formula, as metallurgy history.

Last edited:

- Joined

- Feb 24, 2014

- Messages

- 240

Your Aside #1 reminded me of our "conceptual clash" with Cliff Stamp half a year ago.

I interpret our experimental data through all the knowledge amassed to date, and the latter is not obvious in the study script, and can not be made obvious, unless I write a 1000-page explanation to each study which no one would read.

We do not do studies for the sake of science, but to fill this or that gap in the sharpening practices, and every our finding is confirmed in real-life cutting settings.

We see in our experiments that the flat ground edge shall not go below 15 degrees per side in traditional (ingot) tool steels, and

below 10 dps in the powder metallurgy "supersteels" and quality higher-end carbon knives, because the apex will not cut without folding.

We had a clash with Cliff Stamp on that, as this contradicts his 5-8 dps best cutting geometry statement.

Cliff faulted our study methods vigorously.

I interpret our experimental data through all the knowledge amassed to date, and the latter is not obvious in the study script, and can not be made obvious, unless I write a 1000-page explanation to each study which no one would read.

We do not do studies for the sake of science, but to fill this or that gap in the sharpening practices, and every our finding is confirmed in real-life cutting settings.

We see in our experiments that the flat ground edge shall not go below 15 degrees per side in traditional (ingot) tool steels, and

below 10 dps in the powder metallurgy "supersteels" and quality higher-end carbon knives, because the apex will not cut without folding.

We had a clash with Cliff Stamp on that, as this contradicts his 5-8 dps best cutting geometry statement.

Cliff faulted our study methods vigorously.

- Joined

- Jun 4, 2010

- Messages

- 6,642

I also can not comprehend why higher angle can remove the burr? At the higher angle I create a new bevel. What is the difference if I sharpen at the higher angle at the first?

The burr is metal that exists outside the angle of the edge. Its flopped to the side opposite the abrasive (no abrasive is 100% efficient at stock removal).

By increasing the angle you get better contact with the burr itself, and reduce the chances of the burr flopping away from the abrasive pressure and flipping.

I also can not comprehend why higher angle can remove the burr? At the higher angle I create a new bevel. What is the difference if I sharpen at the higher angle at the first?

My take is a little different. You will create a new burr when you sharpen at a higher angle.

The best ways I know to remove a burr is to use edge leading strokes. As you use lighter, shorter strokes with higher and higher grits, the burr will get smaller and smaller.

At the end, I just use a very light, very short, edge-leading stroke -- maybe an eighth of an inch long to cut off the burr. A longer stroke or a heavier stroke or a coarser grit will just recreate a new burr.

- Joined

- Oct 11, 2014

- Messages

- 1,040

I'm unfamiliar with that conversation, I'll chase it down, thx.

I find most folks have not been taught to think much less think about thinking. A negative accident of educational history across the last century or so. In spite of this, enough genius was released to find a way to the light of day. Creating huge tension with K12, by virtue of incredible new tools, and accelerating, exponential growth in the knowledge base.

I find most folks have not been taught to think much less think about thinking. A negative accident of educational history across the last century or so. In spite of this, enough genius was released to find a way to the light of day. Creating huge tension with K12, by virtue of incredible new tools, and accelerating, exponential growth in the knowledge base.

- Joined

- Apr 15, 2014

- Messages

- 483

Thank you for your continued work on this kind of stuff. Great read. Very thorough testing. I kind of have a boner for S290 now

- Joined

- Feb 24, 2014

- Messages

- 240

The burr is metal that exists outside the angle of the edge. Its flopped to the side opposite the abrasive (no abrasive is 100% efficient at stock removal).

By increasing the angle you get better contact with the burr itself, and reduce the chances of the burr flopping away from the abrasive pressure and flipping.

HeavyHanded, this is the best explanation of high-angle honing I've ever heard. I couldn't say better myself.

In our sharpening protocols the high-angle honing is done on rock-hard felt with 1-micron diamonds.

It removes the wire edge and cleans metal damaged in grinding at the root of the burr to the clean unstressed steel.

- Joined

- Jul 21, 2020

- Messages

- 47

@woowootzblade

Hi, thanks for your info but i have two questions

1) I'm what consiste the "rolling test"

2) You said the non super steer where better at this, do you have the link or something where you test this ones?

Hi, thanks for your info but i have two questions

1) I'm what consiste the "rolling test"

2) You said the non super steer where better at this, do you have the link or something where you test this ones?