-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which do your prefer for bushcraft/camping - D2 or 1095

- Thread starter Bearzilla911

- Start date

jfk1110

Gold Member

- Joined

- Mar 9, 2013

- Messages

- 26,553

Steel really.doesn't matter to me personally..... I take care.of em the same no matter what kind of steel.....

It'd. Probably be more about the manufacturer and their heat treat rather than the steel.....Dozier's D2 is up there and lots of the guys here do a great 1095 blade!!!!

It'd. Probably be more about the manufacturer and their heat treat rather than the steel.....Dozier's D2 is up there and lots of the guys here do a great 1095 blade!!!!

- Joined

- Oct 23, 2025

- Messages

- 25

I guess any steel that is used on a decent knife in the available market will do. However, from performance stand-point, why not pick 14c28n or AEB-L over those 2? There can be an argument that D2 holds it's edge for a longer time, but you mentioned it being a bushcraft/camping knife and in my experience, you don't need much abrasion resistance there. Now if you did some hunting on the side then it would be a diferent conversation as that requires some abrasion resistance. But even then, something like 14c28n at 62HRC with cryogenic treatment, will give you pretty good edge retention while being though. 1095 at 56 HRC is my sleep paralysis demon. But in all seriousness, heat-treatment and edge geometry play a huge role into this segment of knives, that i would rather find out that the heat-treatment is good. I would rather take a good heat-treated 1095 than a badly heat-treated super steel.

Last edited:

- Joined

- Apr 25, 2007

- Messages

- 3,516

AEB-L would be my choice.

J. Doyle

Knifemaker / Craftsman / Service Provider

- Joined

- Feb 17, 2008

- Messages

- 8,330

I'd take 1095 personally out of the two you listed. But that part above?......"well heat treated" 1095 shouldn't be all that tough. Probably 'good enough' but could be way better.....But a well heat treated 1095 has that toughness

Between the 2 options, D2.

Most of the knife people listed use thickness for toughness. Some companies run their 1095 soft, at around 55-57 HRC, which many considered no good, instead of the "golden standard 60+ hrc", which people touted this forums. Yet, for some companies listed, it is ok but not for other...

A thick D2 knife is about as "tough". For the same design , D2 cut more, carves more does more. People seem to focus too much on the natonning, which is more optional by OP. If you don't have to stay off grid weeks, or having a diamond stone which is pretty cheap nowadays, the sharpening difficulty is largely negated.

Most of the knife people listed use thickness for toughness. Some companies run their 1095 soft, at around 55-57 HRC, which many considered no good, instead of the "golden standard 60+ hrc", which people touted this forums. Yet, for some companies listed, it is ok but not for other...

A thick D2 knife is about as "tough". For the same design , D2 cut more, carves more does more. People seem to focus too much on the natonning, which is more optional by OP. If you don't have to stay off grid weeks, or having a diamond stone which is pretty cheap nowadays, the sharpening difficulty is largely negated.

Ebbtide

Gold Member

- Joined

- Aug 20, 1999

- Messages

- 7,984

Yes.Steel really.doesn't matter to me personally..... I take care.of em the same no matter what kind of steel.....

It'd. Probably be more about the manufacturer and their heat treat rather than the steel.....Dozier's D2 is up there and lots of the guys here do a great 1095 blade!!!!

Buy the whole knife.

Don’t be dependent on one component.

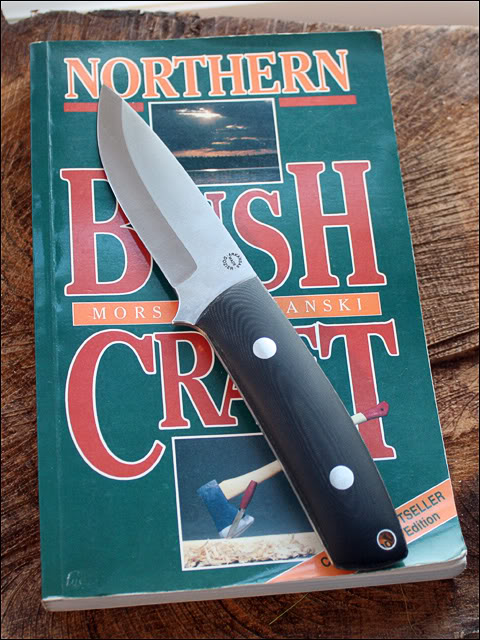

Either will do. I spent my money on this.

- Joined

- Jun 22, 2020

- Messages

- 654

1095 all the way

Bearzilla911

Gold Member

- Joined

- Nov 3, 2018

- Messages

- 75

Depending on what you do/where you use your knives. The semi-stainless properties of D2 versus non-stainless 1095 do play a part in my preference, which goes back and forth between these two steels. For instance, If I am going out to be in the woods and i know it will be rainy or humid, the 1095 better be coated or it will take additional effort to keep the rust down, i.e. they need to be wiped down and oiled. Now some of my favorite knives I own are TOPS knives in 1095 and ESEEs in 1095, but there are instances where I just won't grab one of those and will go with something in D2. Like most of the rest of us here, I have plenty of knives in higher end steels, but don't always grab one of those, versus something in the drawer of beaters, which I why I narrowed down to these two prevalent steels in the original post.

Tritium

Gold Member

- Joined

- Mar 6, 2016

- Messages

- 532

Depending on what you do/where you use your knives. The semi-stainless properties of D2 versus non-stainless 1095 do play a part in my preference, which goes back and forth between these two steels. For instance, If I am going out to be in the woods and i know it will be rainy or humid, the 1095 better be coated or it will take additional effort to keep the rust down, i.e. they need to be wiped down and oiled. Now some of my favorite knives I own are TOPS knives in 1095 and ESEEs in 1095, but there are instances where I just won't grab one of those and will go with something in D2. Like most of the rest of us here, I have plenty of knives in higher end steels, but don't always grab one of those, versus something in the drawer of beaters, which I why I narrowed down to these two prevalent steels in the original post.

Life is short. Enjoy the good ones if you got them.

Ebbtide

Gold Member

- Joined

- Aug 20, 1999

- Messages

- 7,984

If you’re picking a 1095 user, and don’t mind it looking like an old hammer, then I wouldn’t be too concerned about oiling it on a rainy day in the woods.

For years before the internet my go to outdoors knife (bushcraft wasn’t a thing yet) was my trusty Schrade Sharpfinger. Camping, fishing fresh and saltwater, a little hunting. You name it.

After the initial patina developed (BBQ Sauce….surprise!), the blade only got a light dusting of orange rust once.

After a long day on a partyboat, cutting up sea robins for bait, too little sleep & too much sun and beer….

I didn’t freshwater wash the knife when I got home. Thru the day it was wiped with a rag after each use, but the salt residue stayed.

I noticed the next day and a squirt of WD40 and some 000 steel wool and it was good to go.

(Now if I were wading in the surf, that’s a place for stainless. )

Just don’t store it in a wet sheath (or leave it salty).

Maybe take Ed Fowler’s advice and rub your finger on the side of your nose & then on the blade when out and about.

For years before the internet my go to outdoors knife (bushcraft wasn’t a thing yet) was my trusty Schrade Sharpfinger. Camping, fishing fresh and saltwater, a little hunting. You name it.

After the initial patina developed (BBQ Sauce….surprise!), the blade only got a light dusting of orange rust once.

After a long day on a partyboat, cutting up sea robins for bait, too little sleep & too much sun and beer….

I didn’t freshwater wash the knife when I got home. Thru the day it was wiped with a rag after each use, but the salt residue stayed.

I noticed the next day and a squirt of WD40 and some 000 steel wool and it was good to go.

(Now if I were wading in the surf, that’s a place for stainless. )

Just don’t store it in a wet sheath (or leave it salty).

Maybe take Ed Fowler’s advice and rub your finger on the side of your nose & then on the blade when out and about.

Bearzilla911

Gold Member

- Joined

- Nov 3, 2018

- Messages

- 75

Ha, haven't tried that one.Maybe take Ed Fowler’s advice and rub your finger on the side of your nose & then on the blade when out and about.

- Joined

- Jan 28, 2025

- Messages

- 146

His parole officer only lets him choose the classics. Or its back to the slammer.Why are you limited to 1095 or D2?