Okay, so I read through that entire article (love that site btw). I did not see anything that either supports or refutes either argument about stropping. The way I think of it is this: After a fresh sharpening, the edge is at its maximum potential. The cutting edge is going to last the longest from this point. Through use, the apex is going to become fatigued and become "dull." Now you can strop it and bring it back to a reasonable level of sharpness, but it will not cut as long as it did after the initial sharpening because there is still more fatigued steel there than can be removed by stropping. In theory, the edge retention will become less and less with each subsequent stropping. This has been somewhat proven by a friend of mine who does some cut testing.

In regards to Maxamet, you most definitely can get a good edge with abrasives that aren't hard enough to abrade the carbides. This does effect the longevity of the edge however. I did some long term testing on Maxamet a few months back and ran into some issues when using something other than diamond to sharpen. Before performing a cut test, I put Maxamet through my normal progression of 200-1000 diamond and then finished it on 1200/1600 grit ceramics. My results were good but not quite to the level I expected from Maxamet. After a conversation with

DeadboxHero

DeadboxHero

, I ran the test again after using a strictly diamond progression (200 to 1000) and it resulted in a 24.38% increase in edge retention. I think abrasives matter a ton in the performance of these super hard, exotic steels since the matrix is much harder than normal (measured at 69.2 HRC for this particular knife), and key to holding those ever important carbides in place for maximum performance. This is obviously all based on my experience, so take this for what it's worth.

TL;DR: You can get any steel sharp with most abrasives. To get the maximum performance, however, you need to use the correct abrasives.

This was the part about stropping BARE removing material and is coupled to images of it (6th and 7th images):

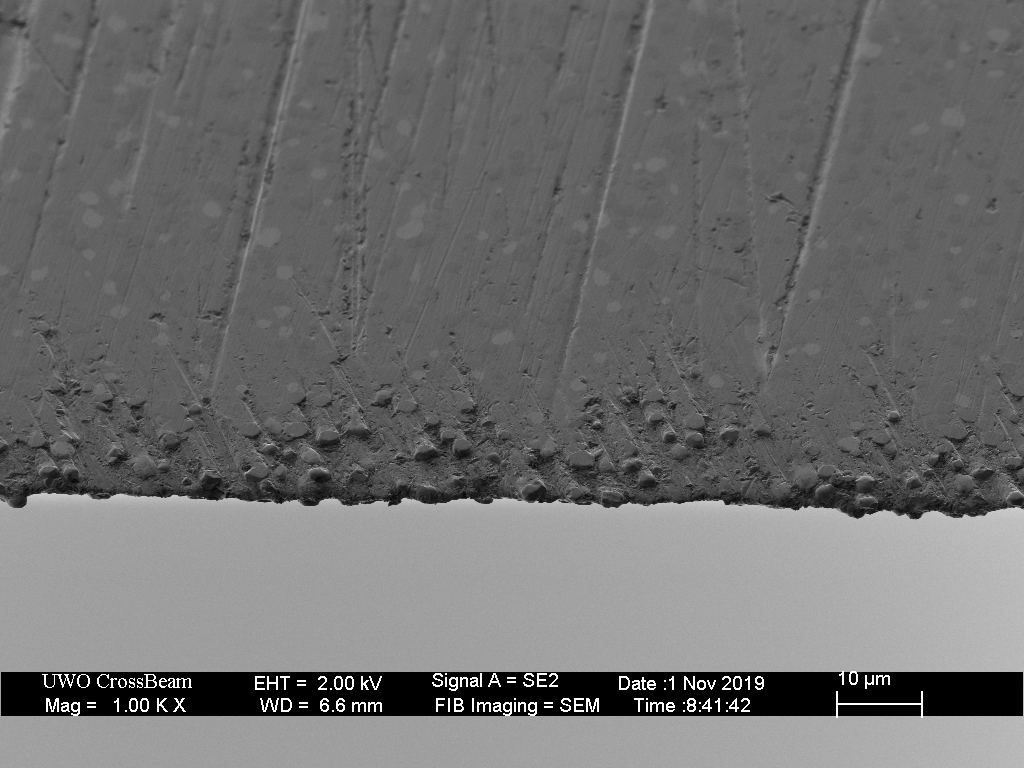

Straight razor edge following 100laps on linen, immediately following honing on a Belgian Coticule. Keenness is REDUCED, due to micro-chipping of the edge. This could also be called “foil-edge removal.” The broken edge is partially reformed...

The entire next section details abrasion from stropping without compound. For stropping WITH compound (as was the original context), those images+descriptions are found in the "Pasted Strop" section starting here:

https://scienceofsharp.com/2015/02/09/the-pasted-strop-part-1/

In regard to "after a fresh sharpening", stropping with abrasive IS "sharpening". Using proper technique, it produces a microconvex edge with the lowest stable (i.e. most durable) apex diameter you are likely to achieve prior to cutting. However, once this edge is worn down to the sufficiently thicker apex diameter to become a nuisance, it's likely that a LOT (relatively speaking) of material needs to be removed from the bevels to return to the geometry you desire, and stropping at high grit to get there may simply take too long so we move to a lower grit hone (preferably hard and flat) and cut a larger bevel (at low angle) before doing the finishing strop = "resetting the bevel".

I think that is what you are typing about. Yeah, stropping back the edge over and over again is just increasing the bevel angle in the microconvexity, leaving an edge that while equally thin is apex diameter is slowly becoming less and less acute = requires more force to cut = wears more on the edge = worse and worse edge retention.

For the maxamet, yup, abrasives are key, although

i doubt that the matrix is really any harder, rather the carbide content is so much higher in distribution that the Rockwell test picks up more of this in its measurement = harder steel despite same martensite matrix hardness. Someone can correct me on that. It's similar for cemented carbide (like the Sandrin blade) - the tungsten carbide is very very hard while the

cobalt matrix is not, but a high ratio of carbide:matrix produces higher RC and, oddly enough, higher toughness. However, cemented carbide is 70-95% carbide vs cobalt binder/matrix and behaves differently than steel (much lower toughness, much higher hardness and wear resistance), Maxamet is only ~17% carbide, but one property that is key is that increased cobalt slows the coarsening of carbides, keeping them fine and well distributed which, as mentioned, factors into what the rockwell test is measuring - having a lot of tiny well distributed carbides throughout the matrix will lead to a high reading.

So consider that - the microhardness of the matrix in maxamet isn't all that different, it isn't really any "better" at holding onto carbides, it simply has more carbides in it. Carbides don't usually "fall out" of an edge (at least I haven't seen support for that beyond arm-chair theorizing), but they can be cracked/chipped and they can be cracked out if precipitated at grain boundaries.

I will note that this is NOT based on my own experience, this is from reading articles by people running experiments and publishing data and images to support their conclusions.

I am happy to be corrected by others with supporting data (and can provide some of my own), but I am simply discussing the mechanisms as they are understood.

Far more important than the precise mechanism is the experience, imho. If a technique works well for you, knowing the "why" is only important so far as needing to explain it and improve it, but knowing that it works is sufficient for the task at hand

But we still want to know why.