- Joined

- Sep 13, 2017

- Messages

- 9,115

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Thank you. I'm glad you're happy with it.Dulling a 119? Had that issue once - I put a mixture of a half cup vinegar, half cup bleach, quarter cup flour onto the hollow ground part, wrap it in aluminum foil (tightly), place it in a pan for no longer than 30m at 405f in the oven, and I usually don't have that problem anymore.

I personally use an SRK sheath fromHale Storm for my 110 as it fits, has the Kydex, but is larger ever so slightly to not smash on it, and holds it in place well.

I might give this a try, thank you.Just throwing in my 2 cents but most plastic sheath inserts I've run into, if removable from the sheath, can be form fitted/adjusted by

using a heat gun or hair dryer. Maybe that might apply here, maybe not.

I think what is happening is the belly is scraping the leather up and down as it rattles so almost like a strop to an extent.Old style, no liner.

View attachment 2220409

New style, removable plastic liner, but does not contact the edge.

Not sure how the knife is getting dulled, as it's edge is just contacting leather.

View attachment 2220408

Yep this was in my mind as well. I really like this sheath as well and the design so I'm willing to put in a bit of effort to keep it. I might take out the plastic insert all together and try to wedge it with just leather.Maybe you could wedge a strip of leather or cardboard between the sheath body and the insert so the blade is held firmly.

Probably be fiddly to fit but once done it’d be worth it.

Buck told me it was to prevent rattling but evidently it doesn't in my case, even if it was to prevent rattling I don't really see how it would. Before I sent it in to buck I took out the insert and broke it, for me it was the same (or close enough) whether it was there or not and I hate plastic so getting rid of it is a plus.I pulled the insert out of my sheath forthwith. To be honest I thought it was just there to maintain the shape; like what they put in shoes. For what it’s worth, it was a modern leather sheath for an 80s 440c 119.

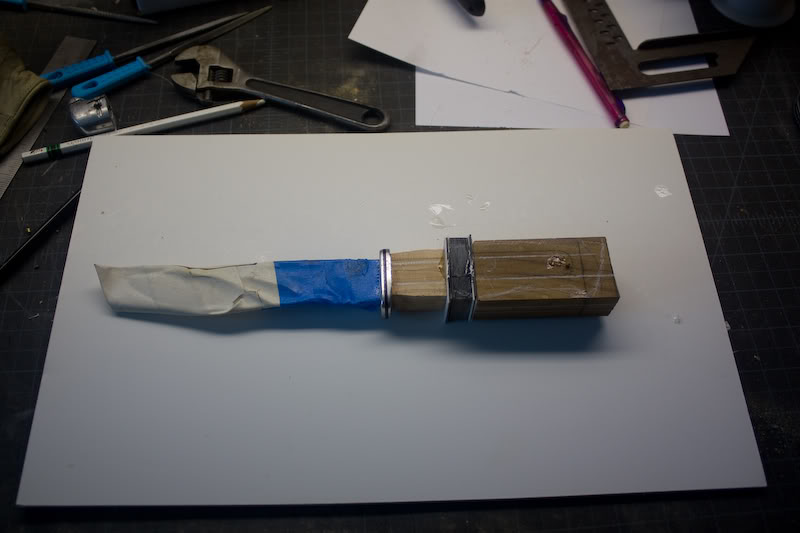

That's pretty interesting and your brahma is beautiful. How did you go about rehandling it?Here is a sheath I made for this rehandled (by me) 119 Brahma.

Made from mil spec webbing belt folded and sewn.

Quick, simple, cheap and easy to make.

The "liner" is 1 inch agricultural irrigation poly pipe, about $2 per meter.

Easy to shape (hairdryer or hold over flame on gas cooker).

It is held in place by a bit of sticky back velcro, same as Spec-ops brand sheaths.

Liner is softer on blades than kydex but still rigid enough not to fold if you land on it, and no rattle!

I've never had any issues with the edge blunting with this knife or the one I use for my Ka-Bar or Randalls.

I emailed them about it and sent in the knife and sheath and it came back with the exact same problem thought to be fair to them they did replace my insert and sharpen my knife which fixed the uneven bevels I put in, I don't even know if they charged me for it, I doubt it though, I think the only thing I payed for was buying the shipping label to send it in. I could try asking again to see if they would provide a new sheath though.Get ahold of Buck and ask for a better sheath. They might fix this problem for future sheaths. Can't hurt to try.

Yeah it's removable. I even took it out and tore apart the one I had before. I don't know how to upload photos here so I can't. But you can find pictures online.Back when I had a 119 ages ago itther was no plastic insert inside the sheath.

Could you verify that the plastic insert is removable? Because if not, it can not be modified.

If it can be removed, could you show us a photo?

Oh that bottom 119 (I assume it's a 119) handle is absolutely gorgeous. I'd love to have handle, if you did do it, can you explain how or link some youtube videos explaining it?A serviceable leather sheath isn’t all that hard.

Lots of good info in the “Sheaths & Such” sub forum.

But beware, once you start they’re like those potato chips…. Ya can’t stop at one.

Have you ever had an issue with the clasp or whatever it's called coming open unintentionally?View attachment 2219713View attachment 2219714View attachment 2219715

As I said. KA-BAR sheath for 120 or Randall model 1. Triple K 6” fits 119 or a PAL-36. 5” fits a USN MKI the 4” with a Western L66. These sheaths carry well and do not rattle.

Thank you. That knife was a “rescue” that I inherited from a member here. Leo had convexed the blade but the handle was beat up and chipped.Oh that bottom 119 (I assume it's a 119) handle is absolutely gorgeous. I'd love to have handle, if you did do it, can you explain how or link some youtube videos explaining it?

I've done that with sheaths that don't have the plastic insert.I think the plastic was put in there to prevent stabbing through the sheath if knife not inserted correctly. On the older sheath style shown above or the sheath of the 124 this is unlikely to happen because of the design.