Resurrecting this one, because the conversion to direct drive has JUST been completed. Took a bit of doing, and there are a handful of considerations...

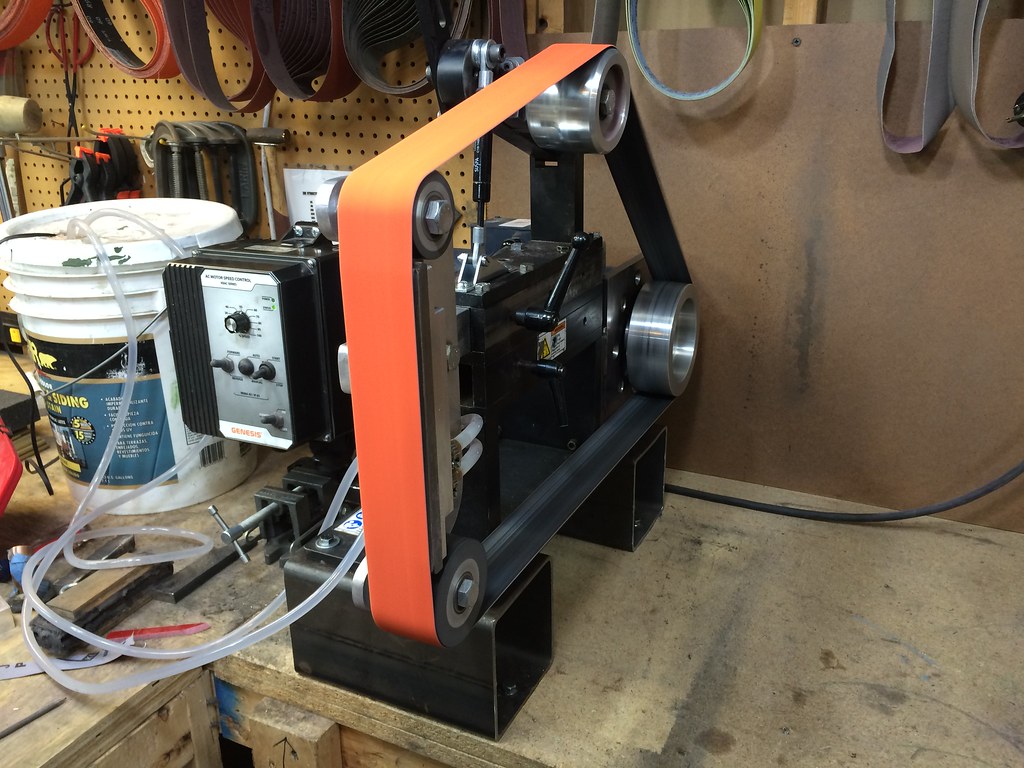

My machinist friend Joe made this one, and it's obviously a protoype. The idea was to make this an EASY conversion, should anyone else want to do this. It assumes you have a 56C face mount motor. Mine is 1725RPM, 2hp, with a KBAC-27 vfd which I run in 2x mode (speed doubled). The adapter plate and motor bracket use the existing pillow block mount holes to bolt to the KMG body.

Other than being easy to do, it also means you aren't permanently modifying the grinder, so should you choose to return it to stock, it's just as simple.

One of the issues had to do with the length of the factory pulley shaft - it's quite a bit longer than a 56C face motor's output shaft. We

could have just had the drive wheel sticking off the shaft a bit, but that's icky. Joe elected to make a custom drive wheel. This one is 5.5" in diameter, with an offset to compensate for the difference in shaft length:

With everything mounted and ready to roll, you end up with this:

As you can tell, I've also added an additional tool slot. That sucks up a lot of real estate, so along with moving the drive pulley back AND increasing the drive wheel diameter, you can quickly run out of belt length. My 12" wheel just barely fits. Nonetheless, every one of my attachments works, including my Bader double billy roll, which eats up belt length like there's no tomorrow. The flat platen and contact wheels are a custom rig I made, with a 2" wheel on top and a 3" on bottom. That's one thing my Wilton got right. Should be a pinch smaller up top (1-1/2" would be dandy), but I had the wheel, so there it is.

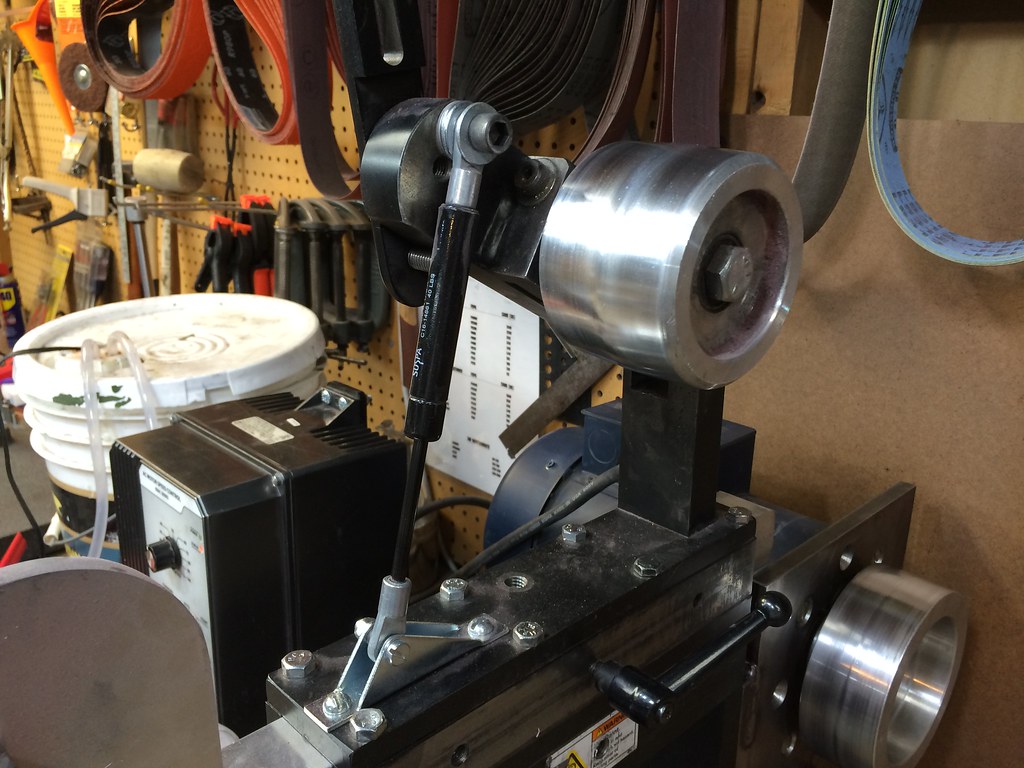

While I'm at it, here's a couple shots of the gas strut tensioner and the monster custom ape-hanger tensioning arm:

Tomorrow will be cleanup and re-locating the spark shields, and preparation for other additions, but this is enough for right now, I'd say. Quick vid of the grinder running wide open with the 12" wheel - previous to this modification, that belt would shift as much as 1/8", and it could NEVER have been run at this speed. The vibration was unbearable. Even the noise is reduced dramatically!