- Joined

- Jan 29, 2014

- Messages

- 1,638

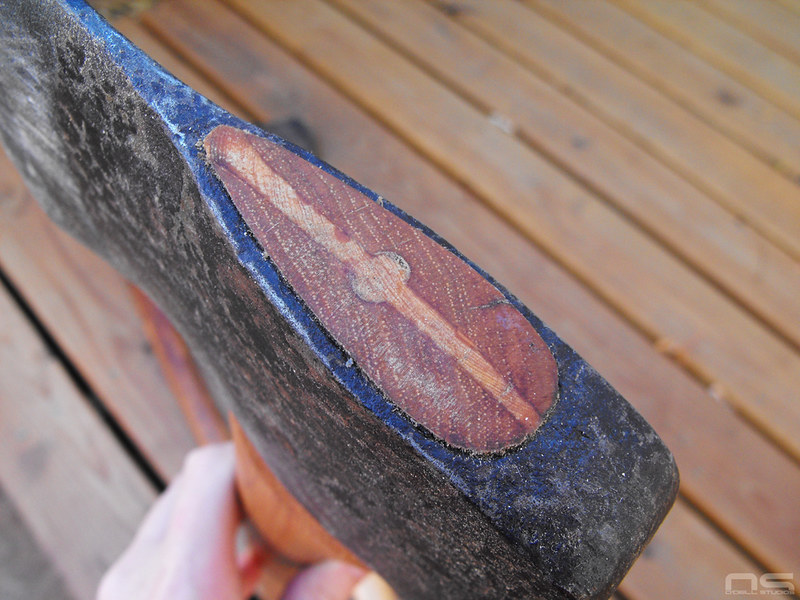

How common is it to crack like that? I thought that mainly happened from forcing too tight of a wedge.

And is the second one on the left also a Plumb? Really like that one. I guess it says "Plumb Jersey lineup". Top handles there.

Left to right; unmarked Jersey 3-1/2lbs (ridges in the eye), NE Old Yank 3-1/4lb (I guess there is speculation that these are Emerson Stevens axes? NE could for sure be New England or North East maybe?), Collins Legitimus 3lb Ct., then the Plumb on the end. Yeah the file name is misleading. It gets to the point where I run out of things to name images to keep them organized.

Some guys on another forum seem to think it is somewhat common. I mean, I am guessing it is very UNCOMMON when you figure the volume of Plumb axes at the time they were being made, but I suspect it is common amongst what we find because cracked axes probably just sat around collecting dust and are easier to come by today. My theory is that mine was a combination of things, the beating it had received during its life, probably me wedging it too hard, and the possibility that maybe some Plumb heads were too hard or had some sort of factory flaw. All or none, or maybe something else.