-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help me understand INFI

- Thread starter David Mary

- Start date

- Status

- Not open for further replies.

- Joined

- Apr 21, 2006

- Messages

- 5,612

I have posted about Infi being A8 (mod) several times and none of the threads went well. Some folks seemed to take it very personally and thought I was insulting Busse or them. I consider A8 (mod) a very good knife steel . None of the threads I posted in had comments from Busse confirming or denying anything .

The products put out in "Infi" were all first rate and built very tough so even if the steel wasn't as tough as it is the knives would still hold up very well. I have two "Infi" knives left and plan on keeping them and have a slab of A8 (mod) sitting around I'm going to have a custom built out of.

The marketing is the only thing I find questionable but the knives are first rate. Making up a name for a well known steel seems strange to me ( see Cold Steel's "Carbon V " as well as "Infi" ) but it has worked well because I have personally seen members here try to burn down threads and get them closed rather than allow people to post the truth. It says a lot about human nature but I won't get into that as this isn't the place.

- Joined

- Jun 9, 2011

- Messages

- 32,390

naw, not you.....ya dont squabble on infi discussions.....Idk how many infi squabbles I've been in on this forum. Lots. This question pops up every few years, sometimes multiple times a year.

I've had infi for 10 years and been using 3v for I'm not sure how many, 7 maybe. I've bent infi to the point it took a set, and beaten infi more than most steels will handle.

I have infi that's rusted and I have 3v that's rusted. I haven't used 3v as hard as infi, as I don't think anyone will warranty that level of abuse. But I've beat 3v plenty hard. My opinion from a user prospective is 3v and infi will both rust close enough that I don't think it matters but like said above 3v probably has a slight edge. Edge retention goes to 3v and toughness to infi. Toughness being that it will deform instead of snap.

Without turning this into an essay, I'd rate infi 8 in toughness 6 in stain resistance (if 1095 is a 3) and a 5 in Edge retention.

The combination of extreme durability, good designs and ergos and a warranty that covers everything but intentionally destroying the blade with a torch make busse still competitive. Yes, other steels are providing competition and other companies are making very durable blades, which is good. Competition is good. Variety is the spice of life.

So no, infi isn't obsolete.

- Joined

- Oct 18, 2018

- Messages

- 8,686

David, don't worry about "that kind of performance".......

My last SYKCO blade was .065" bte.

.065".

My last SYKCO blade was .065" bte.

.065".

- Joined

- Jun 5, 2012

- Messages

- 29,337

Which knife was it?David, don't worry about "that kind of performance".......

My last SYKCO blade was .065" bte.

.065".

- Joined

- Oct 18, 2018

- Messages

- 8,686

It's a newer one, not exactly sure of the model name right now......maybe DT-12?Which knife was it?

It's like a Regulator, but without the Regulator handle. It's got the tnt handle.

- Joined

- Jun 5, 2012

- Messages

- 29,337

Some of the busse and kin can come with geometry meant for busting bricks.It's a newer one, not exactly sure of the model name right now......maybe DT-12?

It's like a Regulator, but without the Regulator handle. It's got the tnt handle.

other memory

Gold Member

- Joined

- Jul 15, 2012

- Messages

- 1,886

It’s a proprietary ht and brand. Lots and lots of hype and marketing. I don’t recall what steel it’s suspected to be. Has a lot of chromium. Do a search, it pops up on metallurgy forums.

Say it enough and it becomes it’s own identity and set of beliefs, rather than a ht and marketing.

Say it enough and it becomes it’s own identity and set of beliefs, rather than a ht and marketing.

- Joined

- Jun 5, 2012

- Messages

- 29,337

Nitrogen instead of loads of chromium if memory serves me correctlyIt’s a proprietary ht and brand. Lots and lots of hype and marketing. I don’t recall what steel it’s suspected to be. Has a lot of chromium. Do a search, it pops up on metallurgy forums.

Say it enough and it becomes it’s own identity and set of beliefs, rather than a ht and marketing.

My understanding is that A8(mod) responds really well to high-end heat treating, kind of like 52100. Busse has his own heat treat down pretty well.

Here's a short video of people pounding a Nexus Centurione into a boulder without damage. The custom heat treat was elaborate.

The steel was A8(mod) at 59 Rc, with multiple thermal treatments. Part of the process was designed to prevent the participation of chromium carbides and transform residual austenite into martensites -- but I don't know specifics.

My Nexus is in this photo, just above a Busse Fat Ash, which porks out at a third of an inch thick at the spine.

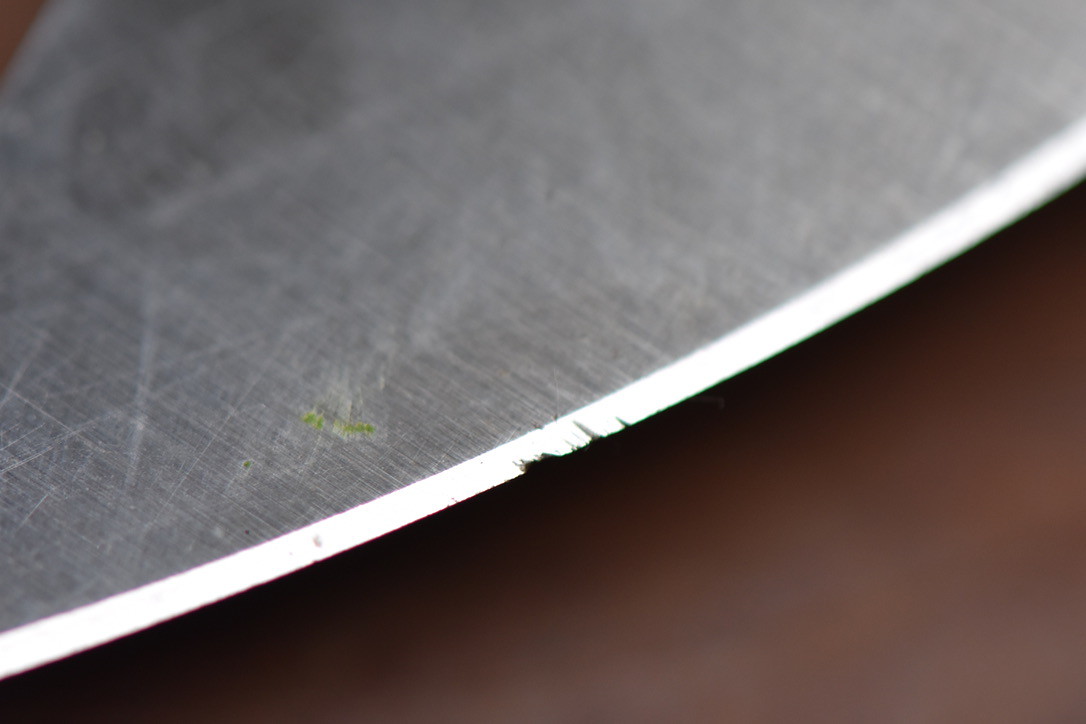

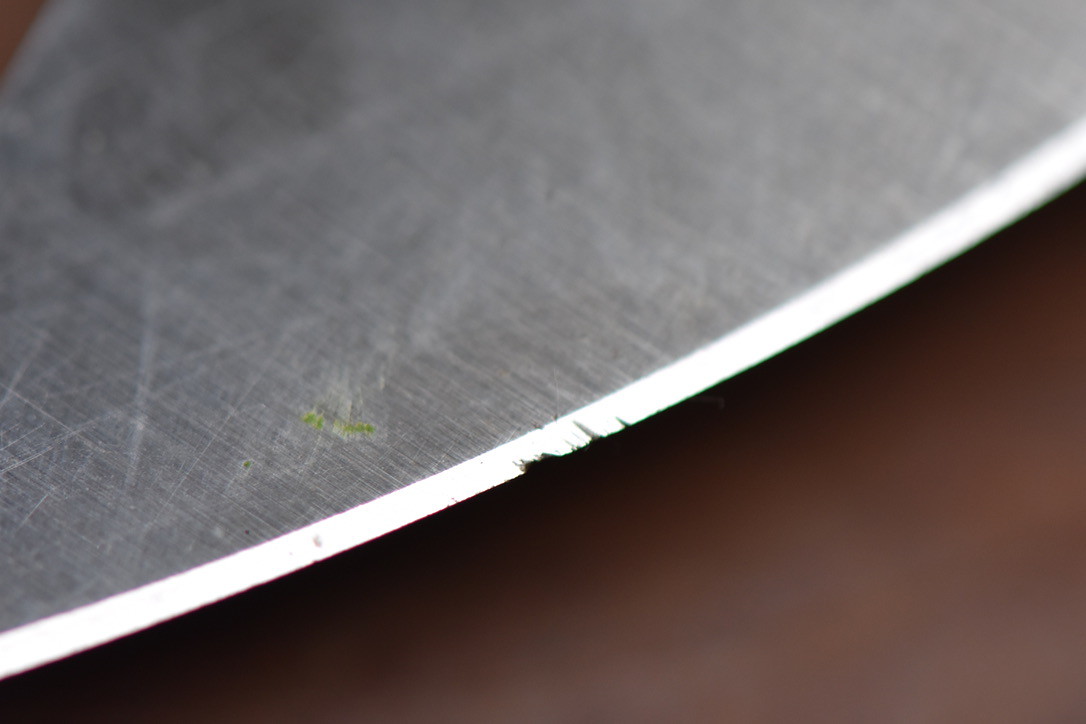

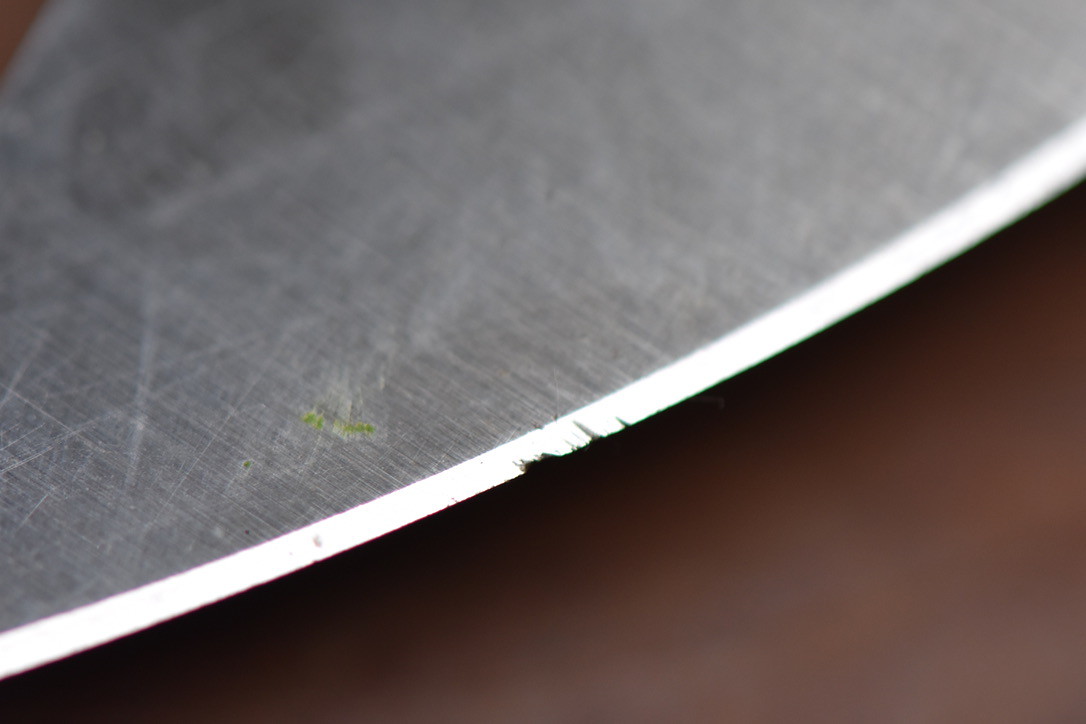

However, you have to get the heat treat right. Here's a cracked blade of A8(mod) that I had custom heat treated by a specialist in Europe known for his work with A8(mod). Something went wrong, I don't know what. But it failed, showing less toughness than a replace of Vanax SuperClean with the exact same geometry.

You might want to contact Moletta. I think he was part of the heat treating of A8(mod). Done right, this steel is really good -- really tough.

Here's a short video of people pounding a Nexus Centurione into a boulder without damage. The custom heat treat was elaborate.

The steel was A8(mod) at 59 Rc, with multiple thermal treatments. Part of the process was designed to prevent the participation of chromium carbides and transform residual austenite into martensites -- but I don't know specifics.

My Nexus is in this photo, just above a Busse Fat Ash, which porks out at a third of an inch thick at the spine.

However, you have to get the heat treat right. Here's a cracked blade of A8(mod) that I had custom heat treated by a specialist in Europe known for his work with A8(mod). Something went wrong, I don't know what. But it failed, showing less toughness than a replace of Vanax SuperClean with the exact same geometry.

You might want to contact Moletta. I think he was part of the heat treating of A8(mod). Done right, this steel is really good -- really tough.

- Joined

- Apr 21, 2015

- Messages

- 206

“A bunch of Italians” made me literally LOL.I think you should look at A8(mod) for the best comparison. That's what the composition is closest to. Who knows about the heat treat.

A8(mod) will be one of the toughest steels, but not in the league of S7 and a bit short of 3V.

For wear resistance, it will be pretty low, between A2 and AEB-L.

A lot has to do with blade geometry. Busse makes pretty brutal edge/blade geometry, so those knives can dish out a real beating. When I compared Delta 3V to Infi in a chopping test of bailing wire -- with edge geometry matched -- the results were pretty close. I have a Knife Research A8(mod) blade with a long, involved custom heat treat that can actually chop up rocks. There's a video of a bunch of Italians doing just that and being surprised by the lack of damage.

I don't know about stain resistance. Vanax is the king there. But the kind of rusting matters. Something like M4 will pit. 3V will sheet rust, making it easy to clean off. I don't know about Infi.

fullswing

Gold Member

- Joined

- Aug 10, 2023

- Messages

- 439

Other than stain resistance, I feel that this video from DBK properly addresses the questions of toughness and edge retention (especially after hard use). They go so far as to shoot it with a rifle and chop a bolt which the knives handle beautifully. Personally, I have a Busse F-16 in INFI which I would absolutely trust to baton a microwave. But the lack of edge retention would make me not reach for a blade made of INFI in most cases in the field. For the blend of properties I prefer, reaching for 3V, AEB-L or Magnacut would be my preference unless I was looking for something purely for chopping or prolonged combat engagements without maintenance.

As with all blades and steels, there is a proper place in the quiver for INFI. But if I had to pick only one knife steel to use indefinitely, the choice would be between the other three.

fullswing

Gold Member

- Joined

- Aug 10, 2023

- Messages

- 439

Is this the video you mentioned in your previous post about people chopping up rocks?My understanding is that A8(mod) responds really well to high-end heat treating, kind of like 52100. Busse has his own heat treat down pretty well.

Here's a short video of people pounding a Nexus Centurione into a boulder without damage. The custom heat treat was elaborate.

The steel was A8(mod) at 59 Rc, with multiple thermal treatments. Part of the process was designed to prevent the participation of chromium carbides and transform residual austenite into martensites -- but I don't know specifics.

My Nexus is in this photo, just above a Busse Fat Ash, which porks out at a third of an inch thick at the spine.

However, you have to get the heat treat right. Here's a cracked blade of A8(mod) that I had custom heat treated by a specialist in Europe known for his work with A8(mod). Something went wrong, I don't know what. But it failed, showing less toughness than a replace of Vanax SuperClean with the exact same geometry.

You might want to contact Moletta. I think he was part of the heat treating of A8(mod). Done right, this steel is really good -- really tough.

Can you please share the screenshot of the article from Larrin you mentioned in the linked post? Really interested to see this.I don't know about the old INFI but the new version is just A8Mod.

Proof here.

Cobalt

Platinum Member

- Joined

- Dec 23, 1998

- Messages

- 17,917

I don't know about the old INFI but the new version is just A8Mod.

Proof here.

So, I have heard this before and it may be true. But to say it's just A8mod, is like saying it's just cpm3v or any other top tier steel. Also, you have to understand that HT is easily half the recipe. Just like for any other steel. You can have an excellent steel, but if the HT is just so so, like in most manufactured cases, then the steel will be so so. I remember testing 3v when it was first being made into knives and boy, it sucked. Chipped like crazy. Now look what it can do with known HT techniques that maximize it's potential

As for your, " I don't know about the old INFI part..." it amazes me how things get lost in time. The original recipe has been posted countless times in the past, but finding it can be a pita. so here it is. Considerably different from anything made today. To be clear, this was the original straight handle run only.

C - 0.5

V .36

Cr 8.25

Fe 87.79

Co .95

Ni .74

MO 1.3

N - .11

I don't know much about INFI. But I looked at Larrin's toughness chart for A8MOD and see that he has it at about 40 ft-lbs. Okay so about the same as AEB-L. Is INFI about the same? Is BUSSE toughness a factor of special heat treatment, or geometry? When I grind an AEB-L chopper at 61 RC to .016" behind the edge, it demolishes hard wood. Wouldn't want to chop cinder blocks with it though. But if I ground the same AEB-L chopper to .035" behind the edge, I suspect it would do that just fine.

So to help me understand:

Let's say that for abrasive wear resistance, Maxamet is a ten, and 8Cr13MoV is a three. What is INFI?

Let's say that for corrosion resistance, LC200N is a ten, and 1095 is a three. What is INFI?

Let's say that for toughness, S7 is a ten, and ZDP-189 is a three. What is INFI?

This thread made me want to finally ask about this:

David, infi is a wood chipper steel with an awesome heat treat. No more no less. I seriously question Larrins toughness number. It is a data point not a line and it is closer to A2 in number. Back in the day there was another modA8 that had only 5% chrome that was closer to A2. That number may have come from that modA8. Seems like that modA8 is gone these days. modA8 with only 0.5% C should be tougher than 3v, but the difference in knives is nearly imperceptible. both resist edge fracture nearly as well as S7, and both beat S7 in edge deformation. S7 has to be HT'd softer and the edge will deform much sooner than the edge on 3v, INFI or modA8. . As for S7 being a ten, that's only because S5 has all but disappeared. lol.

fullswing

Gold Member

- Joined

- Aug 10, 2023

- Messages

- 439

I went down the rabbit hole a bit after seeing this article from Dr. Thomas.

What is the Best Budget Knife Steel?

TLDR;

Looks like 14C28N is worth considering as well.

What is the Best Budget Knife Steel?

TLDR;

Looks like 14C28N is worth considering as well.

Last edited:

hugofeynman

Gold Member

- Joined

- Jan 18, 2011

- Messages

- 1,001

Attachments

Last edited:

goldie

Gold Member

- Joined

- Feb 18, 2000

- Messages

- 4,598

." the lack of edge retention would make me not reach for a blade made of INFI in most cases in the field" Ive used a Hellrazor extensively in the woods and i dont see lack of edge retention; have you used that F16 alot in the field and found it dulled quickly ?

- Status

- Not open for further replies.