My understanding is that A8(mod) responds really well to high-end heat treating, kind of like 52100. Busse has his own heat treat down pretty well.

Here's a short video of people pounding a Nexus Centurione into a boulder without damage. The custom heat treat was elaborate.

The steel was A8(mod) at 59 Rc, with multiple thermal treatments. Part of the process was designed to prevent the participation of chromium carbides and transform residual austenite into martensites -- but I don't know specifics.

My Nexus is in this photo, just above a Busse Fat Ash, which porks out at a third of an inch thick at the spine.

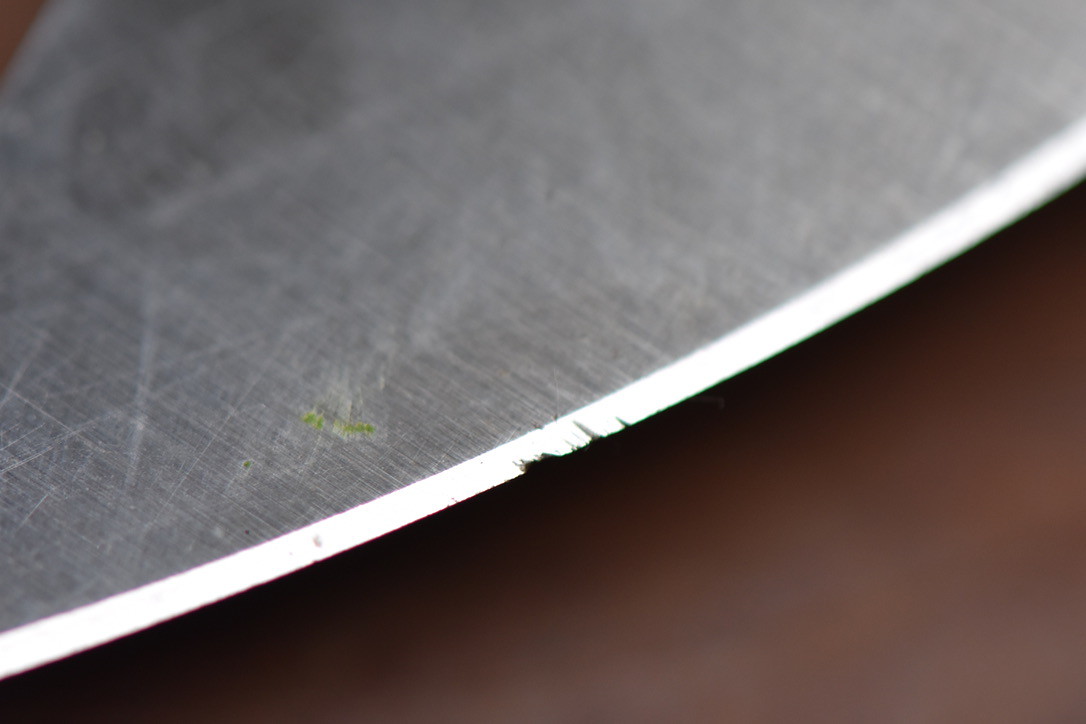

However, you have to get the heat treat right. Here's a cracked blade of A8(mod) that I had custom heat treated by a specialist in Europe known for his work with A8(mod). Something went wrong, I don't know what. But it failed, showing less toughness than a replace of Vanax SuperClean with the exact same geometry.

You might want to contact Moletta. I think he was part of the heat treating of A8(mod). Done right, this steel is really good -- really tough.