- Joined

- Apr 25, 2009

- Messages

- 329

Hello everyone.

I thought that the best way to introduce you all to my work was to do a WIP thread. This isn't really a work in progress, the knife is already finished, so I should be able to get the whole thing posted fairly quickly.

There's probably nothing new or exciting in my knife-making process, in fact much of what you'll see has been directly influenced by (stolen from) other makers' WIP type threads, and I'll try to give credit where it's due.

Here we go:

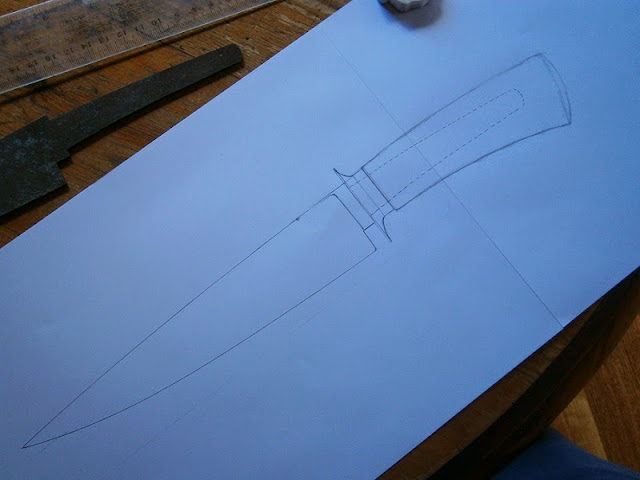

This is the design I decided on. I try to work from the drawing as much as possible. I also made a mild steel pattern to work from.

These are the materials I used. O1 tool steel (5mm thick), 304 stainless pinstock (3mm dia), 304 flat bar (6mm thick), the two smaller pins (2mm dia) are stainless, but I'm not sure on the grade, and not pictured is a chunk of Tasmanian Blackwood.

Here is the pattern I mentioned earlier, clamped to the O1.

Profile scribed.

I use a hacksaw to remove the bulk of the material

Sometimes I use this little file guide type thing to make sure I don't cut beyond the lines.

And this is as much as I'll remove with the hacksaw.

I then move to the grinder. I used a worn 60 grit blaze belt on a 10" wheel for this.

Closer now to the final profile, but still well outside the scribed lines. I use the work rest and platen to take it right down to the lines, this ensures that the surfaces that will be the spine and edge are perpendicular to the flats

Stay tuned for more.

I thought that the best way to introduce you all to my work was to do a WIP thread. This isn't really a work in progress, the knife is already finished, so I should be able to get the whole thing posted fairly quickly.

There's probably nothing new or exciting in my knife-making process, in fact much of what you'll see has been directly influenced by (stolen from) other makers' WIP type threads, and I'll try to give credit where it's due.

Here we go:

This is the design I decided on. I try to work from the drawing as much as possible. I also made a mild steel pattern to work from.

These are the materials I used. O1 tool steel (5mm thick), 304 stainless pinstock (3mm dia), 304 flat bar (6mm thick), the two smaller pins (2mm dia) are stainless, but I'm not sure on the grade, and not pictured is a chunk of Tasmanian Blackwood.

Here is the pattern I mentioned earlier, clamped to the O1.

Profile scribed.

I use a hacksaw to remove the bulk of the material

Sometimes I use this little file guide type thing to make sure I don't cut beyond the lines.

And this is as much as I'll remove with the hacksaw.

I then move to the grinder. I used a worn 60 grit blaze belt on a 10" wheel for this.

Closer now to the final profile, but still well outside the scribed lines. I use the work rest and platen to take it right down to the lines, this ensures that the surfaces that will be the spine and edge are perpendicular to the flats

Stay tuned for more.