That's an awesome blog! Now I have reading material for the next few days

I always use the flats on my sharpmaker. I had no idea edge geometry was so complex. I always thought you wanted to raise a burr during sharpening, but looks like he's saying it's better not to. Or if you do, you have to eventually eliminate it to get back to the actual apex and then ensure it is sharp after removing the burr.

Good job using the flats :thumbup:

You can avoid a burr by sharpening

behind the apex at a low enough angle (edge-leading) to thin the material and only ever micro-chip away the apex:

https://scienceofsharp.wordpress.com/2014/04/16/the-honing-progression/

The edge is thin but rough/toothy... which is actually great for cutting cardboard and rope :thumbup: No detectable burr.

But if you don't raise a burr, you haven't really

sculpted the apex, only thinned the blade material behind it. In apex sharpening you cannot avoid raising a burr, as

Jason B. stated and as is mentioned in the blog:

This foil-edge burr can be reduced, but not eliminated ... Fortunately, this foil is fragile enough to be completely removed by a few strokes of beard shaving and the edge width after breaking off the burr is well below the threshold for comfortable and efficient shaving...

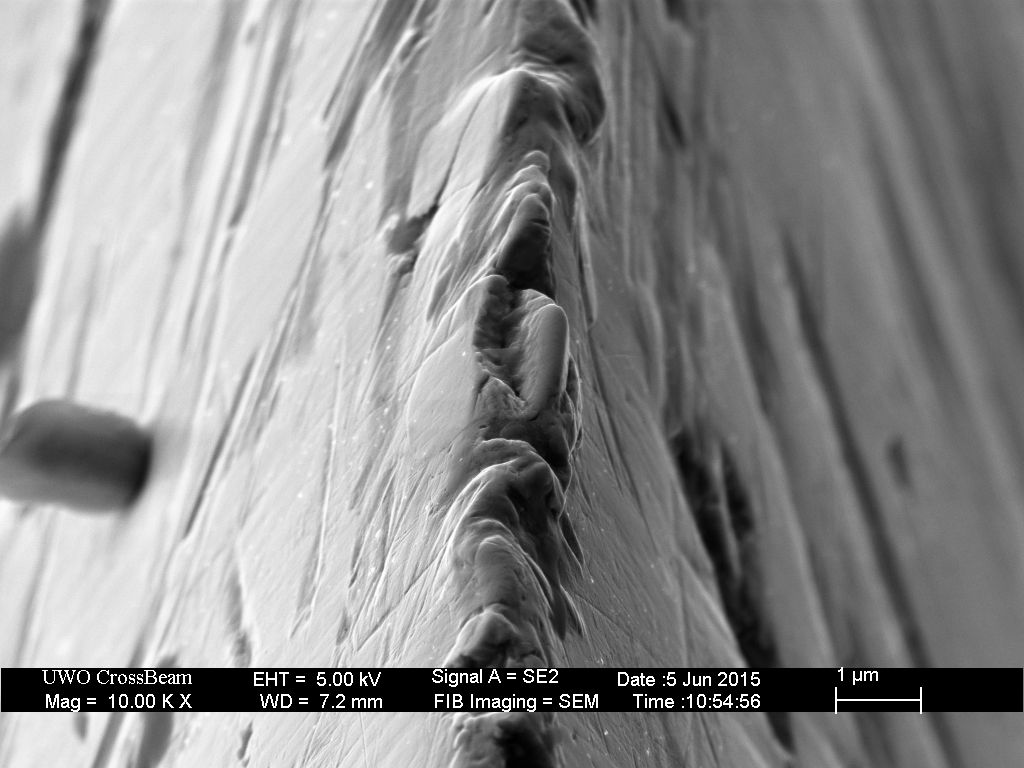

Fresh off the stone before stropping:

After stropping 10X on 0.25-micron loaded leather:

The stropping is what creates the burr as the abrasives sculpt the apex. But after 100 laps, the foil is reduced to a manageable size (note the scale) that will

break-off to a keen edge rather than fold-over and thicken the edge:

ToddS does warn against stopping on bare linen as it can apparently pull off more material than desired, breaking the apex to a thicker diameter? *shrug*

Keep in mind that he his honing razor blades to MUCH higher grit and lower angles. At 20-dps, there is a lot more supporting material to prevent the apex from being torn away stropping.