Hi,

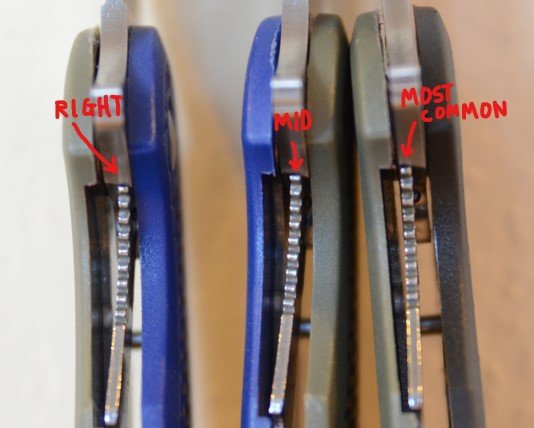

I want people that are experienced in working on liner lock folding knives to comment on this. Below is a picture of 3 knives with the liner lock grind to different position relative to the bottom of the blade.

1) The one on the right is the most common when one buys a new knife, ALL of them regardless of brand comes like this. The liner lock is on the far left side, some doesn't even go in far enough to flush with the side of the blade.

2) The middle one I grind so the liner is in the middle of the bottom of the blade.

3) The LEFT one I grind more to let the liner lock almost go all the way to the right side.

What is the reason why ALL the knives come looking like (1) on the right? I would think it is safer to have the liner at least like the one in the middle so the blade is LESS LIKELY TO FOLD BACK DURING USE.

Actually I would think the best is the one on the left that the liner is towards the right side. As you can see, even wearing out with time, the liner goes all the way to the right, it will be stopped by the metal plate(frame) on the right to prevent from going off the bottom of the blade. This should be the safest position in my book.

BUT before I make this conclusion, I want to hear from experienced knife people whether my conclusion is correct, also whether I am missing something that I should consider.

If I am right, it would be so easy for manufacturers to grind the liner to look like (3). Why not?

Please comment.

Thanks

I want people that are experienced in working on liner lock folding knives to comment on this. Below is a picture of 3 knives with the liner lock grind to different position relative to the bottom of the blade.

1) The one on the right is the most common when one buys a new knife, ALL of them regardless of brand comes like this. The liner lock is on the far left side, some doesn't even go in far enough to flush with the side of the blade.

2) The middle one I grind so the liner is in the middle of the bottom of the blade.

3) The LEFT one I grind more to let the liner lock almost go all the way to the right side.

What is the reason why ALL the knives come looking like (1) on the right? I would think it is safer to have the liner at least like the one in the middle so the blade is LESS LIKELY TO FOLD BACK DURING USE.

Actually I would think the best is the one on the left that the liner is towards the right side. As you can see, even wearing out with time, the liner goes all the way to the right, it will be stopped by the metal plate(frame) on the right to prevent from going off the bottom of the blade. This should be the safest position in my book.

BUT before I make this conclusion, I want to hear from experienced knife people whether my conclusion is correct, also whether I am missing something that I should consider.

If I am right, it would be so easy for manufacturers to grind the liner to look like (3). Why not?

Please comment.

Thanks