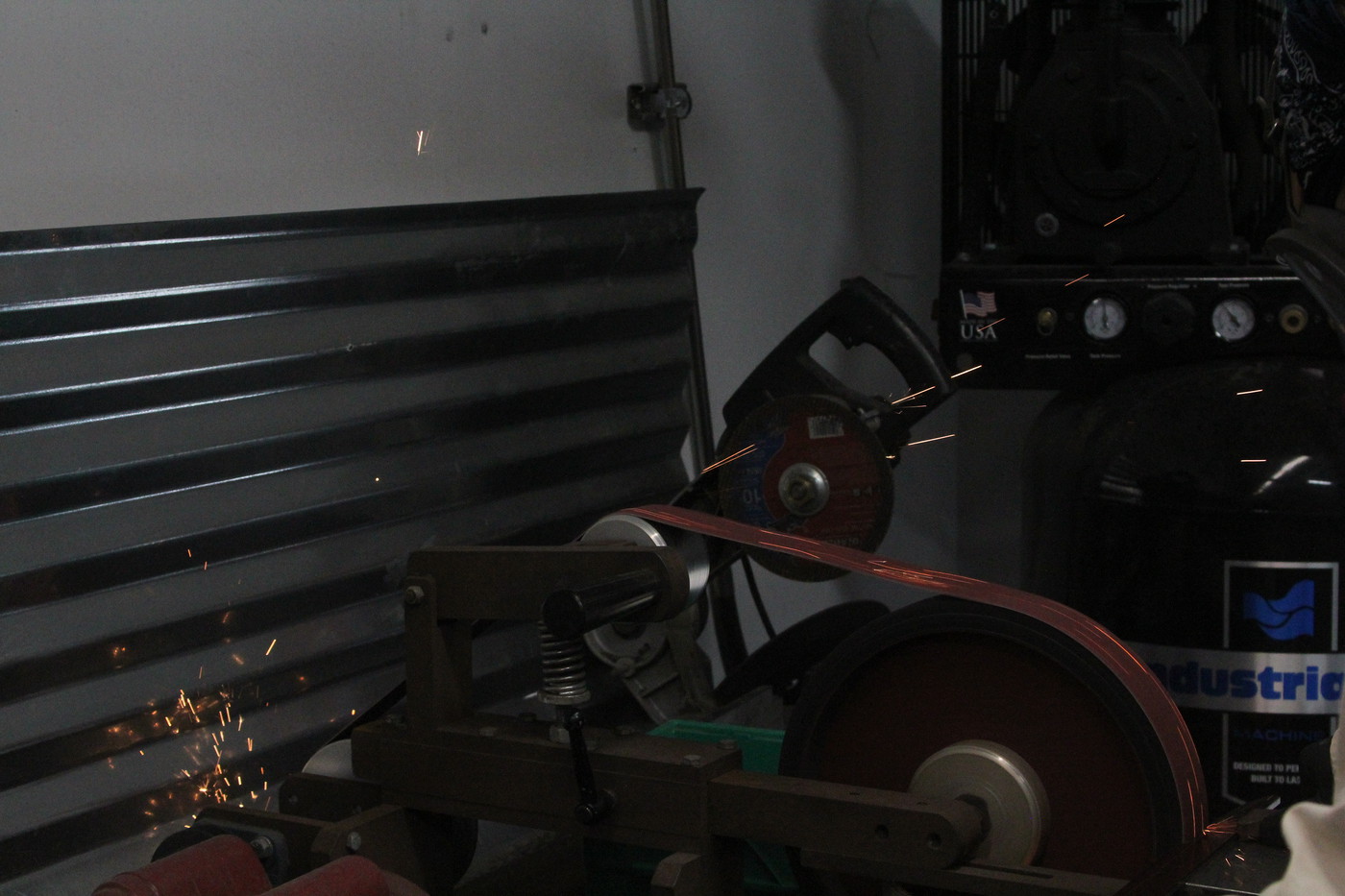

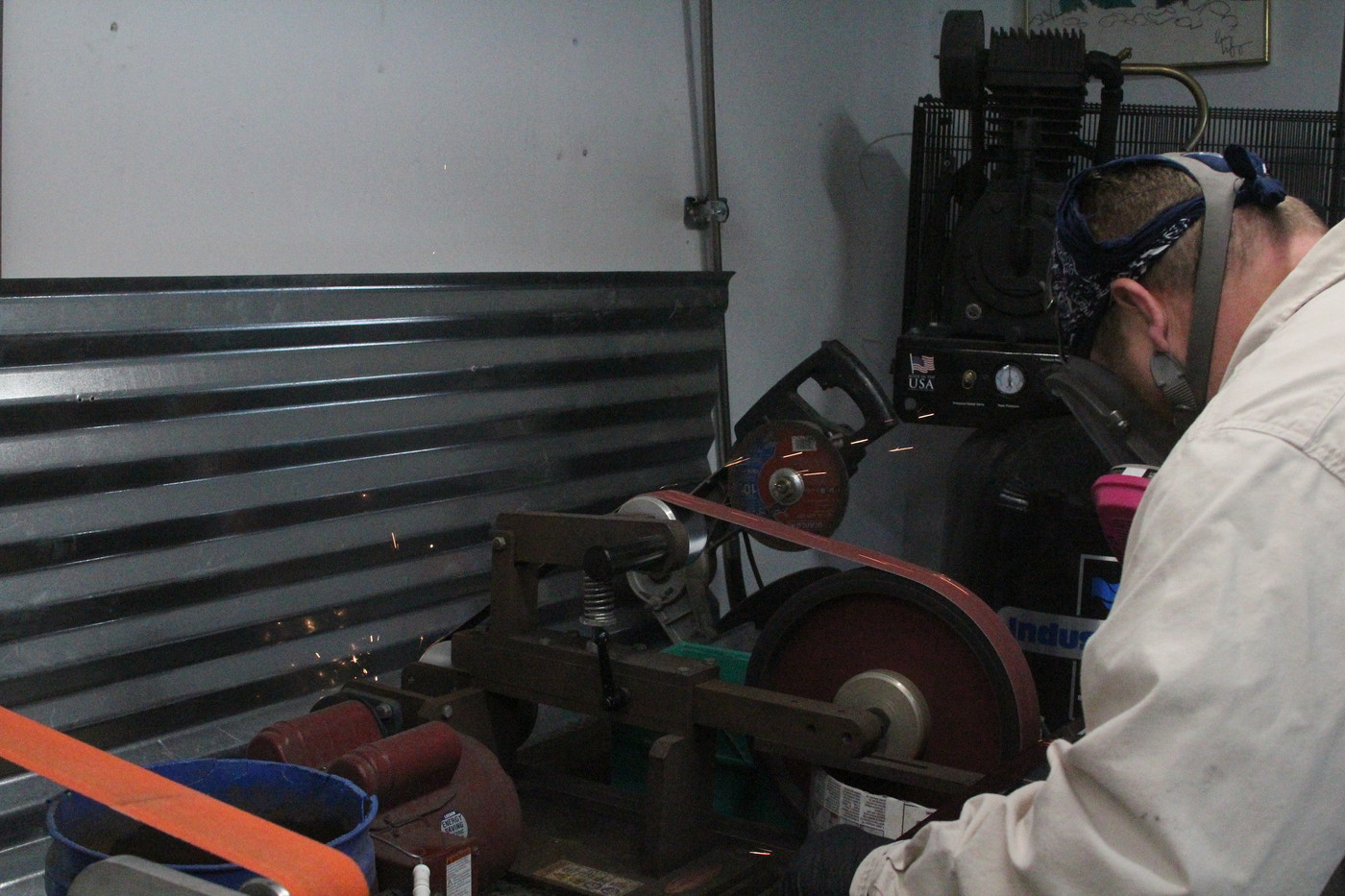

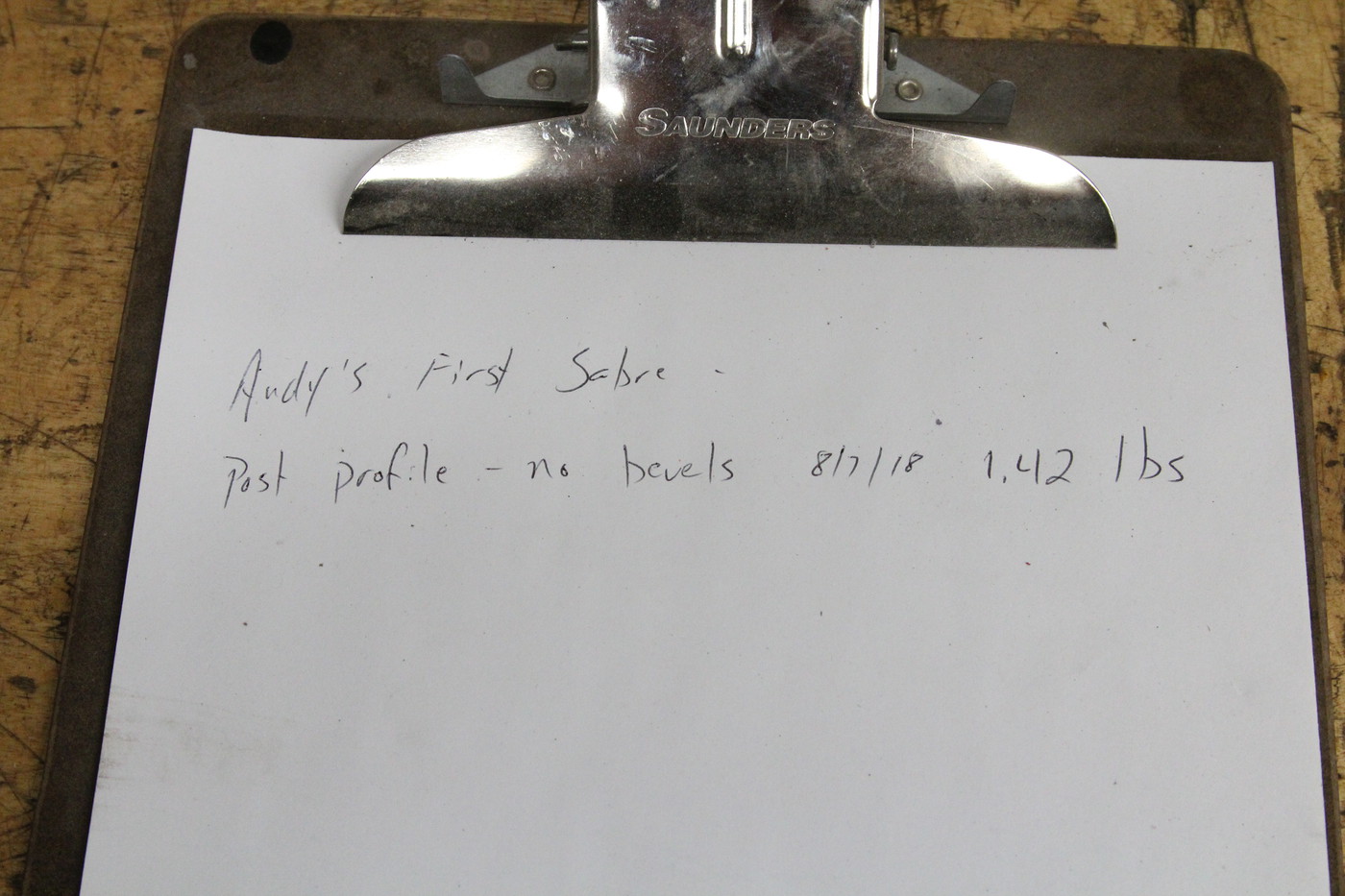

OK. I've spent a couple of Saturdays on this first sword. What I have now is a bade that is ready for HT and my first guard pretty far along. The bladework is totaly different than making knives. There is a distal taper and a fuller that are both tricky to do and kinda compound the difficulty of one another. I think I've figured out a method I like and last weekend I roughed in the fuller. Today I cleaned up the fuller and started the blade grinding which is actually quite simple. This first blade is going to get destruction tested and will likely not even keep its handle. This will give me a couple of chances to make tweaks and changes to the handle, which I will need. Once again, a sword handle is totaly different and I've had trouble designing anything that looks halfway decent.

The next part I was having trouble designing was the guard. I've made a first attempt. All of the fittings of the sword are going to be copper. Today I drew up a vague shape to try to produce. I cut a pattern from micarta and a first attempt from copper. Then I hamered the copper guard to shape. I'm pretty pleased. I was able to thicken the stem, which will become the knuckle guard. I even kept it straight. I cut the piece smaller than the finished piece and thinned the guard to the size I wanted. I think I could have gone way farther here, but I got something pleasing and stopped. I have a couple of pics.

In this first pic I'm getting started with the guard. The blade is roughed, and is sitting beside the notebook. The micarta is sitting out ready to be made into a pattern.

Here you can see the pattern being made. You can see a curl of paper I cut off of the guard, planning to expand the copper to the line in the drawing.

This next pic shows the copper cutout and the micarta pattern. And a coupe of experiments for the pommel.

This pic shows the blade fitted to a slot in the copper blank.

This was after the first heat of hammering. The goal here was to thicken the thinner profile of the copper and keep it straight and squarish.

This was a few heats later. The damn forge is in storage so I was using the torch.

This is where I am at the end of the day. The knuckleguard has not been bent around yet, but is ready to go. The guard is thinned and has the profile to fit the drawing and then given a bit of contour. This will likely be re-worked a few times before the 3rd blade is ready, and the guard has a permanent home (I hope).