When I tried it, lapping film exposed carbides also when starting from the DMT EEF. That was with a glass substrate and wetted lapping film slid onto the glass with no bubbles behind it. Diamond compound on leather cuts better than lapping film from what I've seen. I can probably run a few more test shots for you guys though. I have the lapping film and the Spyderco UF.

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stropping wear resistant steels (S30V, S90V, CTS204P, etc)

- Thread starter Strauss95

- Start date

- Joined

- Jun 4, 2010

- Messages

- 6,642

When I tried it, lapping film exposed carbides also when starting from the DMT EEF. That was with a glass substrate and wetted lapping film slid onto the glass with no bubbles behind it. Diamond compound on leather cuts better than lapping film from what I've seen. I can probably run a few more test shots for you guys though. I have the lapping film and the Spyderco UF.

Is that diamond lapping film or the AlOx variety?

AlOx - thought that's what you were referring to. I'm pretty sure diamond would be fine, but I don't have any of that. The finish would be worse for equivalent abrasive particle size compared to loaded leather stropping of course, but you knew that already.

Last edited:

Ok, last set is ready. I took the edge from the Carborundum 103 and hit it on the Spyderco UF but it was pretty ugly. Carbides weren't cut and we're definitely being torn out. With the stone being as hard and not porous as it is, I could feel when they came loose. When any came loose the honing feel went from dead smooth to like gravel. Anyhow, I decided to start over again on a DMT EEF baseline and then go back to the Spyderco UF to get a little better picture. I stayed to the center of the EEF to get a little better finish since the center wears faster than the perimeter. Here's the baseline:

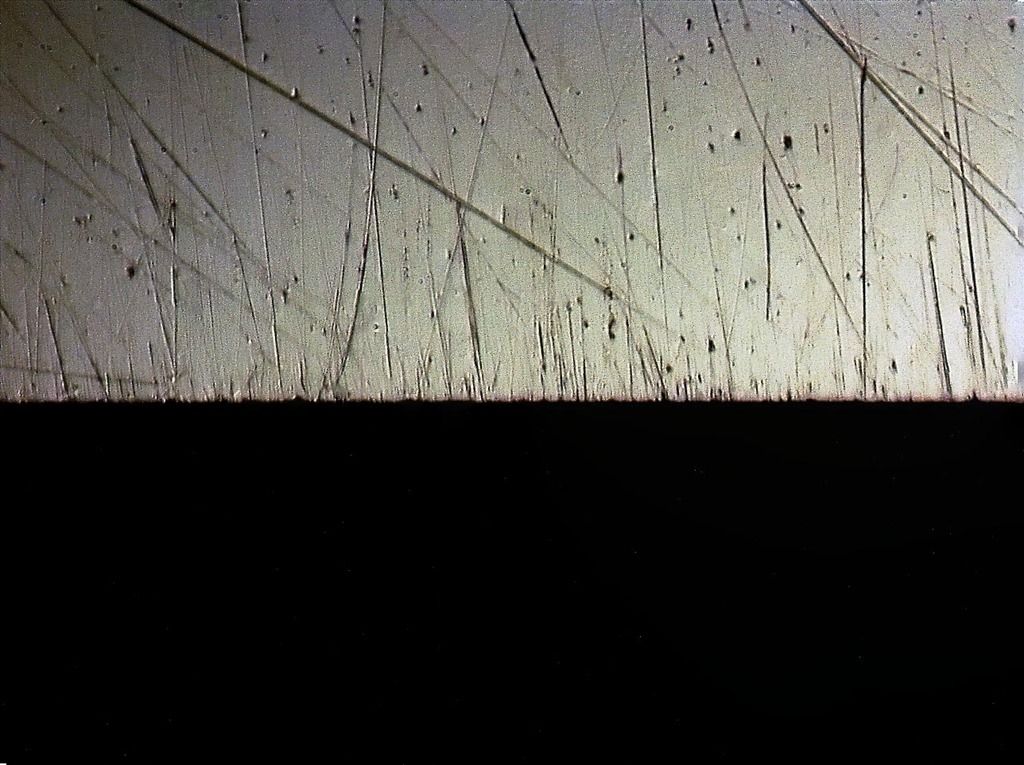

Then quite a while later on the Spyderco UF - this is on the factory surfaced side:

Then another image, this time honed using the side of the Spyderco UF I lapped to my preferred flatness:

The finishes are similar to each other, with the second image having some extra gouges due to carbides coming loose. The edge is better on the shot from my lapped side - and this is almost certainly mainly due to the factory side having those swirled tool marks from the diamond grinding wheel. I could literally feel the edge catching on those lines. Both show some uncut carbides and many cavities from torn-out carbides.

I wasn't too surprised by this result as IIRC the Spyderco UF is just fused alumina, as I recall, basically another form of aluminum oxide.

Then quite a while later on the Spyderco UF - this is on the factory surfaced side:

Then another image, this time honed using the side of the Spyderco UF I lapped to my preferred flatness:

The finishes are similar to each other, with the second image having some extra gouges due to carbides coming loose. The edge is better on the shot from my lapped side - and this is almost certainly mainly due to the factory side having those swirled tool marks from the diamond grinding wheel. I could literally feel the edge catching on those lines. Both show some uncut carbides and many cavities from torn-out carbides.

I wasn't too surprised by this result as IIRC the Spyderco UF is just fused alumina, as I recall, basically another form of aluminum oxide.

- Joined

- Mar 7, 2001

- Messages

- 4,608

Thanks. I recalled Sal in the video said something akin to sapphire, which should be harder than the carbides.

Well, your images is the evidence it's not so.

Are those VC?

I'm wondering if it'll be effective for CrC, like 52100 or VG10?

Appreciate the effort! :thumbup:

Well, your images is the evidence it's not so.

Are those VC?

I'm wondering if it'll be effective for CrC, like 52100 or VG10?

Appreciate the effort! :thumbup:

- Joined

- Jun 4, 2010

- Messages

- 6,642

Of all the images, only the series of DMT EEF and superabrasive stropping made an edge with a perfectly clean line (at this magnification).

I didn't think M2 had enough Vanadium and Carbon to form carbides.

Last edited:

I'm guessing they are vanadium carbides but not certain. M2 contains something like 2% V and 0.8% C IIRC. I haven't got any VG10 or 52100 blades at the moment, so can't help there.

The images are taken with a modified USB scope, a Celestron 5 megapixel - Discovery I think is the name? Good images are really a matter of technique more than the scope. These cheaper scopes take a dog's age and many attempts to get a good focus with.

The images are taken with a modified USB scope, a Celestron 5 megapixel - Discovery I think is the name? Good images are really a matter of technique more than the scope. These cheaper scopes take a dog's age and many attempts to get a good focus with.