chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

SURVIVE! Knives GSO-10

I was lucky enough to get involved in the promotional run of Guy Seiferd's design for a 10" chopping knife. Guy chose to employ Crucible'a CPM-3V, a high end American steel ideal for the tasks that a 10" blade might be put to - decent corrosion resistance matched with impressive impact toughness (twice that of M390) and very high wear-resistance (twice that of D2). I'd seen this steel perform in custom knives by Dan Keffeler with astounding results, so to find this offering from SURVIVE! Knives at the promotional price was ... more than exciting. Guy published design images on his website and FB page.

My initial impression was that he placed too much focus on handle indexing, similar to his early 4" and 5" models. Aggressive indexing can make a knife that fits perfectly in one user's hand virtually unusable for another person, and this may be futher complicated when the environment requires gloves or mittens. Nevertheless, I took the risk, and three months after placing my order, I had a GSO-10 in hand.

I should first comment on the packaging. The sturdy carboard box shipped USPS priority mail is exactly the right size for this knife. Within is stamped Guy's SURVIVE! emblem, along with a business card, and classy wood-straw rather than obnoxious peanuts or crumpled paper. The knife itself lay within the nesting material in its Kiah-dex sheath wrapped neatly in brown paper. Myself and my colleagues (I openned it at my place of employment) wondered if it was to be a museum piece!

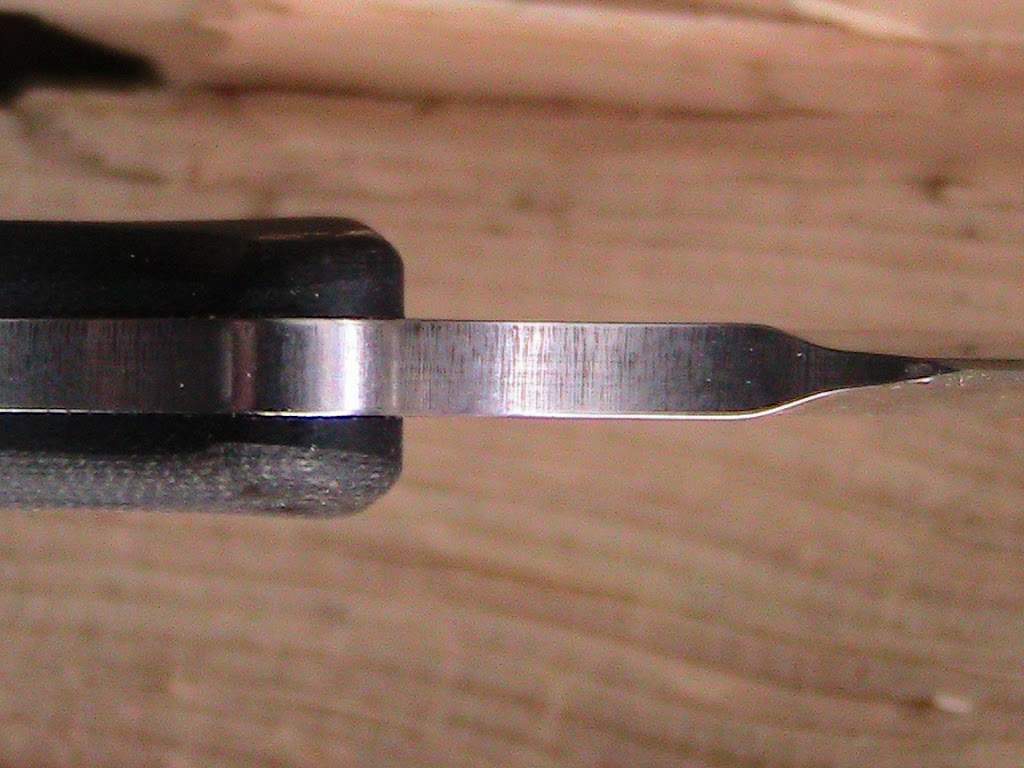

The entire blade, including beneath the scales, and also the micarta had a light and even coat of mineral oil (a guess - it was clear and unscented, readily wiped away). As another owner has noted, even the handle screws were aligned! Examining the knife closely, the bevels are perfectly even, the stone-wash exquisite, the edge polished to perhaps 600 grit? Guy could enlighten us on that point. Along the spine and handle belly into the choil, rough machine-marks are visible, deep enough to catch a finger nail, a striking contrast to how smooth the stone-wash finish and edge are. The marks do not bother me, so it's up to Guy and his customers whether further refinement is in order there.

The handle scales were a rich black with the oil on the surface of the micarta - I've worked that out somewhat, prefering the gray & black intonations common to black micarta slabs. The edges of the slabs are rounded nicely, while the wide flats have a series of small valleys milled out to enhance retention, something thay accomplish well while maintaining a smooth, non-abrasive feeling. I am a fan of canvas micarta. The handle slabs are attached by slotted screws and stud-pillars, easily removable with a flat screwdriver or washer, which is necessary to access the "hidden lanyard hole" - a feature I've not seen on any tool before. The lanyard hole is fairly narrow. I tried doubled-over paracord, but the fit is tight and the cord is immovable once the slabs are re-attached. I prefer a single strand so that the cord is easily moved aside in case the pommel needs to be used for impacts.

(along side a SRKW Rodent 9)

More to follow...

I was lucky enough to get involved in the promotional run of Guy Seiferd's design for a 10" chopping knife. Guy chose to employ Crucible'a CPM-3V, a high end American steel ideal for the tasks that a 10" blade might be put to - decent corrosion resistance matched with impressive impact toughness (twice that of M390) and very high wear-resistance (twice that of D2). I'd seen this steel perform in custom knives by Dan Keffeler with astounding results, so to find this offering from SURVIVE! Knives at the promotional price was ... more than exciting. Guy published design images on his website and FB page.

My initial impression was that he placed too much focus on handle indexing, similar to his early 4" and 5" models. Aggressive indexing can make a knife that fits perfectly in one user's hand virtually unusable for another person, and this may be futher complicated when the environment requires gloves or mittens. Nevertheless, I took the risk, and three months after placing my order, I had a GSO-10 in hand.

I should first comment on the packaging. The sturdy carboard box shipped USPS priority mail is exactly the right size for this knife. Within is stamped Guy's SURVIVE! emblem, along with a business card, and classy wood-straw rather than obnoxious peanuts or crumpled paper. The knife itself lay within the nesting material in its Kiah-dex sheath wrapped neatly in brown paper. Myself and my colleagues (I openned it at my place of employment) wondered if it was to be a museum piece!

The entire blade, including beneath the scales, and also the micarta had a light and even coat of mineral oil (a guess - it was clear and unscented, readily wiped away). As another owner has noted, even the handle screws were aligned! Examining the knife closely, the bevels are perfectly even, the stone-wash exquisite, the edge polished to perhaps 600 grit? Guy could enlighten us on that point. Along the spine and handle belly into the choil, rough machine-marks are visible, deep enough to catch a finger nail, a striking contrast to how smooth the stone-wash finish and edge are. The marks do not bother me, so it's up to Guy and his customers whether further refinement is in order there.

The handle scales were a rich black with the oil on the surface of the micarta - I've worked that out somewhat, prefering the gray & black intonations common to black micarta slabs. The edges of the slabs are rounded nicely, while the wide flats have a series of small valleys milled out to enhance retention, something thay accomplish well while maintaining a smooth, non-abrasive feeling. I am a fan of canvas micarta. The handle slabs are attached by slotted screws and stud-pillars, easily removable with a flat screwdriver or washer, which is necessary to access the "hidden lanyard hole" - a feature I've not seen on any tool before. The lanyard hole is fairly narrow. I tried doubled-over paracord, but the fit is tight and the cord is immovable once the slabs are re-attached. I prefer a single strand so that the cord is easily moved aside in case the pommel needs to be used for impacts.

(along side a SRKW Rodent 9)

More to follow...