sorry for the delay - tied up tonight, tomorrow I will likely be not available - so trying to get this out now. Ok ... so following up on Stacy's comment, it does appear that your controller might likely be using a "pulse width modulation" on the output ... which means is cycling the heating element on and off to varying percentages of time .. in effect increasing or decreasing the heat output over time. Good.

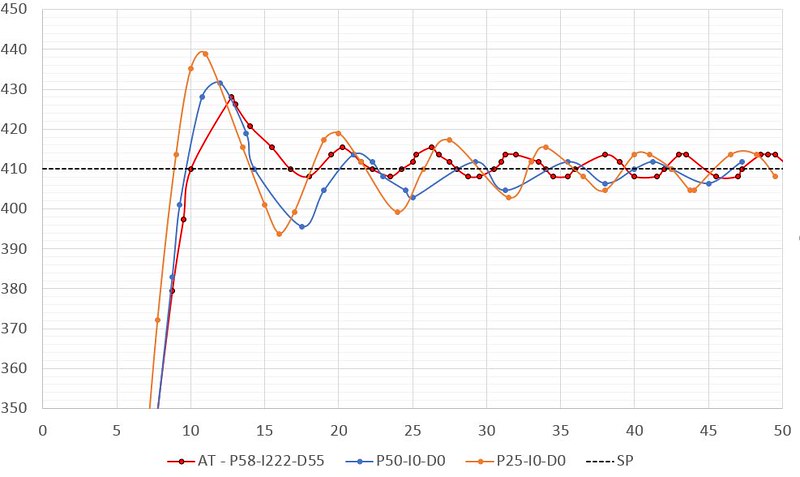

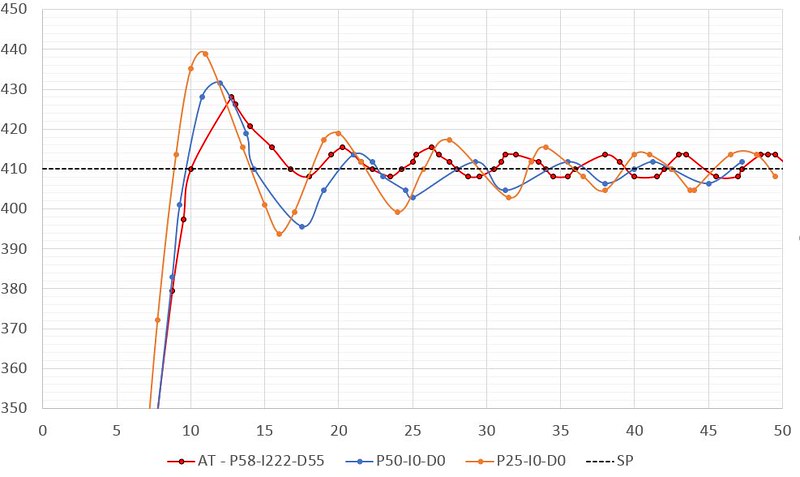

I went back through the thread, and found your "manual tuning guide". Looks like the controller is using a different definition of the PID coefficients than I had been used to. Inverse in fact. So in effect, for this controller a smaller value of the P coefficient actually leads to more of a "sudden" transition from on/off in the vicinity of the set point. So... to make the effect of the proportional control "smoother", or "gentler" - you need a BIGGER value of P. Small values of P will cause overshoot and oscillations. Bigger values will cause a slower approach to the set point, AND more of a downward offset at steady state. Same thing with the integral coefficient: small values will cause the integral input to have a quick and profound influence on the heater - bigger values (the manual says it is actually using "seconds" for units on this coefficient) will slow down the influence of the integral input. This makes sense in the data just above: when you shifted the P value from 50 to 25, you would expect a more profound influence of the proportional input - which is what you see (more overshoot).

Here is what I would suggest. First, confirm from the manual that a value of 0 for the integral and differential coefficient actually turns OFF that portion on the control (because the actual control equation includes a function of 1/I .. and if I is zero, the ratio is infinity. bad. If the controller does not "understand" that this means the function is turned off ... look for the way you actually turn "off" that function.

Start with integral and differential OFF (proportional only). then start with a rather "soft" proportional value (in this case, a HIGH value of the P coefficient. Try, say, 200. What SHOULD happen if the controller is working correctly is that the oven should heat SLOWLY towards set point, then level out and stay constant (no oscillations) at a lower temperature with some offset from the set point. If you still get overshoot and oscillations with a value of 200 for p, then INCREASE is in increments until you see the smooth asymptotic behavior described above. From there, decrease the P coefficient in increments: the offset should get smaller and smaller, and eventually you will start to see oscillations. When you see them, BACK OFF on the coefficient (make it bigger) until you get back to the point where there are no oscillations (but you have an offset). keep the proportional coefficient at that point and do not change it! NOW turn on the integral function, but use a BIG value of the integral coefficient (i.e. "slow" influence from that function). As a guess I would say something like "if using only P the oven took 5 minutes, then set the value of the integral coefficient to 600 (which is 600 seconds = 2*5 minutes). this should have the effect of decreasing the offset. Keep making the value of the integral coefficient smaller (in smallish increments): you should see the offset continue to decrease .. and eventually you will start seeing oscillations again. as before, when you see this back off (make bigger) the integral coefficient until you have no oscillations.

STOP THERE. the differential function is way too touchy to use unless you have an extremely robust system. However, now you KNOW what your offset is - so just change your set point for the controller to hit the actual temperature you want. For example, if while tuning your set point is 200F, but your actual achieved temperature without oscillations is 190 (offset = -10degrees) .... when you want to actually use the oven, just give the set point to the controller as 210. with the offset of -10 degrees, you will then achieve something really close to 200 ... which is what you really want. make sense?

Sorry if I confused things: the definitions for this controller are inverse of what I was used to in the past :-( . BTW - "autotune" is somewhat over-rated. Take the tuning stepwise like described above, and it really is not difficult at all.

Again, I am not sure if I will be able to input anything tomorrow (looks like we have a pet we have to put down :-( ). post what you find and I will catch up....