Never given it a lot of thought, but I assume the slots or reference marks on clamp style sharpening devices (Lansky, KME) represent the angle as measured at the nip of the clamp jaws, i.e. the real angle is dependent on whether the blade is clamped at the very back of the blade or somewhat "deeper".

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

angles on clamp style devices

- Thread starter olddogrib

- Start date

- Status

- Not open for further replies.

chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

Never given it a lot of thought, but I assume the slots or reference marks on clamp style sharpening devices (Lansky, KME) represent the angle as measured at the nip of the clamp jaws, i.e. the real angle is dependent on whether the blade is clamped at the very back of the blade or somewhat "deeper".

DMT provides a chart with their Aligner for referencing different blade widths. https://www.dmtsharp.com/resources/dmt-faq/

But keep in mind that as the arm swings away from the "start" point, the angle of incidence changes, so what is 15-degrees at the start point will end up being lower on either side of the clamp. Only when the blade is NOT clamped (e.g. Edge Pro) can you avoid this.

But keep in mind that as the arm swings away from the "start" point, the angle of incidence changes, so what is 15-degrees at the start point will end up being lower on either side of the clamp. Only when the blade is NOT clamped (e.g. Edge Pro) can you avoid this.

That is a wide spread misconception. From the Wicked Edge FAQ:

There is considerable (and mostly misinformed) debate on the web about angle change on guided sharpening devices along the length of the blade. Contrary to most peoples intuition, the angle does not change throughout the straight length of the blade, no matter how long the blade is. It will change through the arc of the belly of the knife where the edge dips to the spine. The geometry at work is planar in nature and because the stones are able to rotate on the guide rod, they are able to maintain the same plane of contact with the blade when the blade is straight. When the blade begins to curve, the stone enters a new plane at a different angle. This new angle can be more acute or more obtuse depending on its distance from the pivot point of the guide rod. You can adjust for this effect by mounting the blade with the tip at varying distances from the clamp. Using a Sharpie marker to color in the bevel will help you quickly establish the optimum front to back positioning for your knife by allowing you to visualize the way the stone tracks along the curve. You can use the record keeper supplied with the kit to jot down the settings for each of your knives and repeat those settings for future sharpening sessions. When you've adjusted so that the angle is perfectly consistent throughout curvature of the blade, you may have a slightly wider bevel at the tip because the edge is being cut from the thicker stock of the blade near the spine, unless the knife has a distal taper.

- Joined

- Apr 12, 2009

- Messages

- 13,198

No, it is not the angle as measured at the nip of the clamp but it depends on the maker. Some assume the knife edge protrudes 1/2" others 5/8" etc.

With the Lansky specifically, it IS the angle measured at the 'nip' of the clamp (assuming 'nip' means the very edge of it's jaws, anyway). I verified this with my own Lansky setups (I had two). Because they reference it so, it's impossible to actually sharpen at the same angle as what's marked on the clamp, because the blade's edge is unreachable by the hone if placed flush with the edge of the clamp's jaws. But other makers will vary as to how they reference the marked angles; I seem to recall the GATCO's marked angles are dependant on placing blade's edge further out.

With ANY clamped setup, the real angle will decrease as the edge of the blade is moved further out in the clamp, away from the clamp's jaws.

David

chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

That is a wide spread misconception. From the Wicked Edge FAQ:

...The geometry at work is planar in nature...

Right there they are dead wrong. The geometry of the clamp system is NOT "planar", it works on a 3-dimensional right circular cone. As the blade extends away from the pivot point, the adjacent and hypotenuse lengths increase while the "opposite" length holds constant (i.e. the cone's height remains constant while the circumference of its base gets larger). As a result, the angle at the edge necessarily drops in proportion to this distance.

Lagrangian once incorrectly argued the same way they do, I don't think he ever printed a retraction, but he did follow up with a thread and complex graphical representation of how much the angle deviates as you move from that "start" point in front of the clamp to distances further away: http://www.bladeforums.com/forums/s...Guided-Rod-Sharpeners?p=13110990#post13110990

A short distance between the cutting edge and the pivot point change the angle on the tip and close to he handle. if the distance is longer, the changes will be smaller.

I use a fixed distance of 28 cm between the cutting edge and the pivot point on my tool Chef. When I sharpen a 25 cm long blqde with a straight edge (no belly) the change is 0,2 degrees on the tip and close to the handle.

A tool with 100 cm distance between the cutting edge and the pivot point will still change the edge angle - but the change is only a few thousends parts of 1 degree.

Thomas

I use a fixed distance of 28 cm between the cutting edge and the pivot point on my tool Chef. When I sharpen a 25 cm long blqde with a straight edge (no belly) the change is 0,2 degrees on the tip and close to the handle.

A tool with 100 cm distance between the cutting edge and the pivot point will still change the edge angle - but the change is only a few thousends parts of 1 degree.

Thomas

- Joined

- Sep 22, 2014

- Messages

- 2,930

You can't trust the preset holes of any system. Too many variables.

If you just want to match the original factory grind, just use whatever holes get close enough. Be sure tonuse a Sharpie to make sure you're hitting the apex.

If you really want to know the true angle, you either need to measure and to the math (trigonometry) or get an angle measure (the one in most smartphones is good enough).

If you just want to match the original factory grind, just use whatever holes get close enough. Be sure tonuse a Sharpie to make sure you're hitting the apex.

If you really want to know the true angle, you either need to measure and to the math (trigonometry) or get an angle measure (the one in most smartphones is good enough).

chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

You can't trust the preset holes of any system. Too many variables.

If you just want to match the original factory grind, just use whatever holes get close enough. Be sure tonuse a Sharpie to make sure you're hitting the apex.

If you really want to know the true angle, you either need to measure and to the math (trigonometry) or get an angle measure (the one in most smartphones is good enough).

^That right there :thumbup: I stick with 15-dps for every cutting tool i use unless too much damage results from it. I know that 15-dps means the height of my spine-center above the origin needs to be 1/4 the distance of the tip-to-origin.

Put another way, 30-inclusive is twice as tall as it is thick. So I 'guestimate' that ratio and go to, using the sharpie to evince how much metal I need to remove to reach the apex, following the same principle that HH recommends elsewhere - work from the shoulder to the apex. I can then add a microbevel to remove any paint left at the apex that i cannot quite see and call it good :thumbup:

With the Lansky specifically, it IS the angle measured at the 'nip' of the clamp (assuming 'nip' means the very edge of it's jaws, anyway). I verified this with my own Lansky setups (I had two).

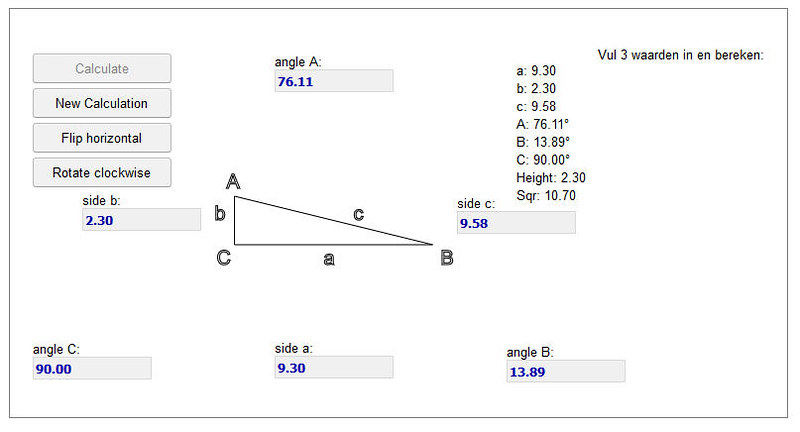

I am sorry David but it is not as can be seen in these two pictures. One is as measured with the angle cube with the rod in the 17 degrees position and the other one is as calculated with the online angle calculator http://www.driehoekberekenen.be/

Frans

Just a question from a "no" nothing guy. Are we not kinda splitting hairs here for the average sharpener?

Yes we are

I use the Lansky mostly on the 20 degrees setting with my pocket knives and my Wicked Edge at the 17 degrees setting with my kitchen knives.

I couldn't care less what the actual measured angles would be. just if the knives cut well at that setting and the repeat ability.

Right there they are dead wrong.

No, they are not.

http://tecniques.sharpening.info/2010/08/does-angle-change-along-length-of-blade.html

It's all relative. The actual angle matters much less than repeating the angle each time that you sharpen.

Good point.

In my opinion it is nice to know what angle my edge really has, and to be able to keep just that edge angle everytime I sharpen the edge - and, I also like to be able to adjust the edge angle, up, or down, in degrees, or parts of degrees, when it is necessarry for me.

If I do not know what angle my edge have - and I change my edge - I do not know where I started, I do not know where I landed, I do not now what distance I have traveled... and.... Really, what can I possbly leran from not knowing? This way of sharpening allways starts from zero, every time.

If I know the edge angle, and change it, I do that for a reason or need. I know where I started, I know where I landed, I know the distance I have travel - and from that facts can I learn. This way of sharpening starts from zero only one time, the first time - never more. What you have learn can you use in the next sharpening you do, and the knowledge follows you the rest of your life.

Thomas

If I do not know what angle my edge have - and I change my edge - I do not know where I started, I do not know where I landed, I do not now what distance I have traveled... and.... Really, what can I possbly leran from not knowing? This way of sharpening allways starts from zero, every time.

If I know the edge angle, and change it, I do that for a reason or need. I know where I started, I know where I landed, I know the distance I have travel - and from that facts can I learn. This way of sharpening starts from zero only one time, the first time - never more. What you have learn can you use in the next sharpening you do, and the knowledge follows you the rest of your life.

Thomas

chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

You did notice in your link that the angle changed as he moved up the blade, did you not? Did you follow the link I presented to you?

The only way to make a edge with exactly the same edge angle all along the edge is to move the pivot point sideways paralell to the edge. I use this method when I sharpen long edges on for example machetes and swords.

My tool for this work with 28 cm fixed distance between the edge and the pivot point. A marking on the guide rod gives this distance. This make it very easy to have control of this distance.

Some machetes has a very big belly. This means that the distance between the pivot point and the edge gets shorter = the angle will be steeper. When I come to a belly like this i adjust the pivot point so that I allways have 28 cm distance. It works perfect.

When the distance change between the pivot point and the edge - the edge angle also change.

Thomas

My tool for this work with 28 cm fixed distance between the edge and the pivot point. A marking on the guide rod gives this distance. This make it very easy to have control of this distance.

Some machetes has a very big belly. This means that the distance between the pivot point and the edge gets shorter = the angle will be steeper. When I come to a belly like this i adjust the pivot point so that I allways have 28 cm distance. It works perfect.

When the distance change between the pivot point and the edge - the edge angle also change.

Thomas

I showed this picture on another thread for some days ago. This is a old tool I still use sometimes to grind convex edges. This tool use what I wrote about above. On the sharpener I have marked a startpoäng and a stop point and also marked the degrees between this to points. The edge is on the start point in this picture - and the edge angle inntheir point are 15 degrees, you can se that on the built in protractor in brass in the upper right corner.

When When I move the knife forward the distance between the pivot point and the edge will be longer. When The edge come to the stop point I have change the edge angle with 5 degrees wich means that the edge will be convex with a 5 degree convex sphere.

On the guide rod I have stop collars - and I can only move the edge between these stop collars, on this pictures from the start point to the stop point. i can of cause adjust the stop collars so I can start the sharpening in any angle - and I can make any convex sphere in wanted degrees - and I can repeat it.

Thomas

When When I move the knife forward the distance between the pivot point and the edge will be longer. When The edge come to the stop point I have change the edge angle with 5 degrees wich means that the edge will be convex with a 5 degree convex sphere.

On the guide rod I have stop collars - and I can only move the edge between these stop collars, on this pictures from the start point to the stop point. i can of cause adjust the stop collars so I can start the sharpening in any angle - and I can make any convex sphere in wanted degrees - and I can repeat it.

Thomas

You did notice in your link that the angle changed as he moved up the blade, did you not? Did you follow the link I presented to you?

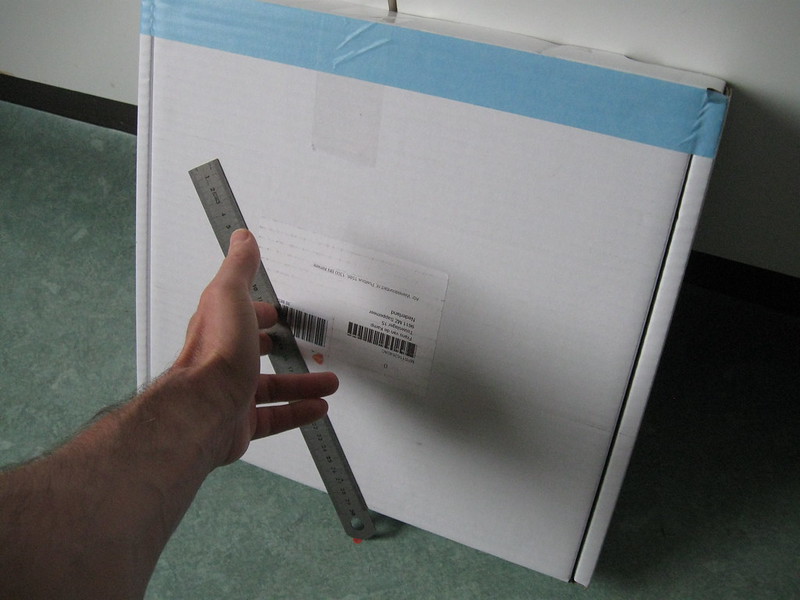

I followed that thread when it was posted and at that time it was already clear to me that the angle does not change. English is not my native language so I will try to explain with a few photos and an experiment that you can easily do yourself.

Here is a carton box placed at an angle with the blue masking tape representing the edge, the ruler representing the sharpening stone and the red dot on the floor representing the pivot point. In each position, the ruler lays flat on the box and the angle of that plane (which is the plane of the knife edge) does not change. I can not make it any simpler.

Frans

- Status

- Not open for further replies.