-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barmaley's Aggregated Questions Thread

- Thread starter Barmaley

- Start date

- Joined

- Feb 5, 2008

- Messages

- 1,004

I have the same BelOMO 10x. Have had it for many years.

Me too. Can't beat it at the price.

If you, or anyone else, is familiar with USB microscopes, would you please recommend a good power range for detailed knife edge examination?

Thank you!

I wish I could recommend that but I am not experienced enough. Maybe other senior members can help.

- Joined

- Oct 30, 2018

- Messages

- 219

Have you ever noticed how the old guys know stuff? Sometimes you don't listen to them and later on you figure out "Hey that old dude really was spot on. Why didn't I listen when he told me what to do?"

David Martin, is spot on here. A coarse DMT is not coarse enough to do real work. Apologies to Obsessed. If your edge is butter dull, a coarse DMT is going to take forever to reform the edge. Something closer to 100 grit is the ticket. A coarse Crystolon should work. I know the DMT XXC works. If you "don't like the feel of diamonds" then the DMT XXC might not be for you. The Barynox Manticore gets raves from a lot of people here too. It's very coarse.

What you may not realize is this: You do 90% or more of your grinding on the FIRST most COARSE stone you use. It's going to get all of the wear and tear. Ceramic stones like the Spydercos, or finer diamonds like the DMT EF and EEF just barely, barely get any wear at all. They will last forever and ever and ever. As long as they are used for finishing like they are intended.

Coarse stones are for shaping and forming the initial bevel. Medium, fine, (and beyond) stones are for polishing.

Your coarse stones might get replaced eventually. If you do enough grinding to make that necessary. Your medium and fine stones shouldn't get replaced ever. Unless you make the mistake of thinking that a medium or fine stone is for grinding. IN which case you can wear it out. In the process you will wear out your arms and make yourself very frustrated. Use the coarse stone. It's your friend.

Brian.

I don’t disagree, my first ‘proper’ stone was a DMT coarse. It worked, even on relatively dull knives - but I would be there for 30 mins or so to apex an edge.

I have since bought coarser stones and for the relative price of a coarse SiC stone it really is a no brainer

Thank you David Martin, SubMicron and Brian for good explanation!!! I will try to do it myself!

Brian, if I have only one coarse stone and I want it to cut very fast and to last, what it would be?

What is the real grain of Spyrderco or in other words natural grain? What material is it made of?My understanding is that the Spyderco Fine and Spyderco Ultrafine are the same stone, just finished differently.

Brian, if I have only one coarse stone and I want it to cut very fast and to last, what it would be?

What is the real grain of Spyderco or in other words natural grain? What material is it made of?

I maintain an abrasives reference chart so I've spent time trying to answer that. These stones are so dense I believe that functionally speaking no natural grain size can be given. It is better thought of as a solid material like steel, which also technically has an internal grain structure but in which the macro-structure of teeth on a saw or file determines how it will cut.

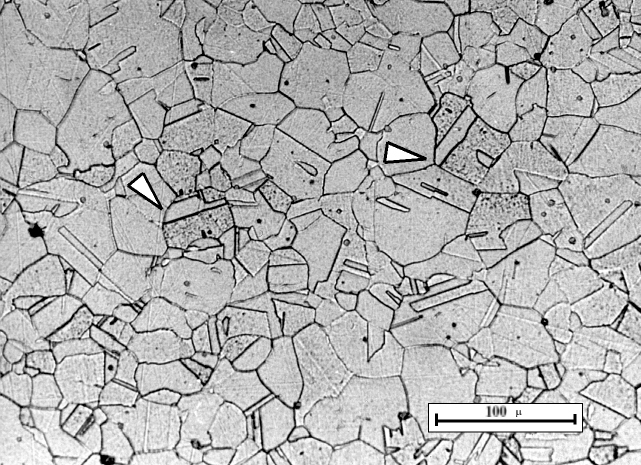

This is a micrograph of 99.9% alumina ceramic, not specifically the Spyderco type.

This is a micrograph of stainless steel:

David Martin

Moderator

- Joined

- Apr 7, 2008

- Messages

- 19,520

alumina ceramic and most sites put the grit at 1500. DM

What is the real grain of Spyrderco or in other words natural grain? What material is it made of?

That question is interesting from an academic/scientific perspective. From a knife sharpening (or metal grinding) perspective, you should probably be interested in how it grinds compared to another abrasive. With ceramic specifically, the grinding is unusual. Because it's not all metal removal (grinding). Part of it is burnishing, or plastic deformation. The ceramic is so hard that it "smears" the metal as you rub it against it. Burnishing makes metal smoother by moving it around like a spatula on cake icing. In this case, burnishing is part of the action and grinding is part of the action. The rough equivalent of these actions, with a Spyderco Ultra Fine, is about the same as a 3 micron abrasive. It produces a mirror polish on the small number of steels I've used it on. Not a super bright crazy mirror, but a very shiny bevel never the less.

Brian, if I have only one coarse stone and I want it to cut very fast and to last, what it would be?

I have only tried a small number of very coarse stones. Of those few I have tried, I like the DMT XXC the best. I have had the XXC for 8.5 years now (had to go check my order via email). It seems to cut just as fast as when I got it. It may have decreased a bit, but it seems very fast; leaves very clear grind lines that make it super duper obvious where I am grinding.

Other people love the Norton Crystolon, Coarse. I have never tried one, though I do own a Medium Crystolon. The medium worked pretty well for me, but has smoothed over. I think I used it incorrectly by not using oil and allowing it to break off new abrasive. I'm told I should condition it with loose silicon carbide. I might do that eventually; for now it sits unused. The Coarse Crystolon is certainly a better bargain than the DMT XXC; something like 1/2 or maybe 30% of the cost. You can also "lean in" to a crystolon, putting about as much force on it as you want.

The XXC isn't exactly delicate, but you don't want to put excessive pressure on it either.

For the record I should say that I don't really do any reprofiling or "serious grinding" by hand any more. I use a 1x42 belt sander for most of my sharpening now, except for touchups, which I will still do by hand.

Good luck with your purchase.

Brian.

Using Silicon Carbide sandpaper, on top of glass, with water on the sandpaper, I rubbed the stone in a circular motion until it was flat. I scribbled all over it with pencil, and kept at it until every bit was white and the whole stone was totally flat

I tried pouring 60 grit silicon carbide on glass and rubbing the stone on it but it just dished the glass and started to convex my stone.

I tried an inexpensive 140 grit diamond flattening plate, and it got it flat, but left deep scratches.

Finally I tried the Silicon Carbide sandpaper and it worked great. I took that side to 220 grit, tried it, and then left it there.

On the other side, I started with 220 grit, and kept at it with that grit until that whole side was flat. I then used my Atoma 400 and smoothed that side out more, tested it, and then finished it with 600 grit which leaves it very smooth.

For now that's how I left it. It's now a dual stone...The course side cuts more aggressively than the fine side.

I thought that alumina ceramic in Spyderco can not be cut since the stone suppose to last forever. Is Silicon Carbide sandpaper harder than ceramic? If I use 220 grit sandpaper will I make my Spiderco 220 as well? Why people buy several stones if it is possible to condition any Spyderco stone to any grit?

I am sorry - I guess my questions as dull as my knives (at least at the moment before I learned on how to sharpen -LOL) but is it hard for me to do things without understanding how it works

Last edited:

Stones can get clogged while sharpening on them. My understanding is that it is metal sticking to the surface of the stone and in order to clean it we need to remove the metal from the stones. Can I use any type of acid to chemically remove the metal to clean a stone?

- Joined

- Apr 20, 2018

- Messages

- 4,458

Bar Keeper's Friend (powder, not the squeeze bottle stuff) and a poly brush work very well on diamonds, Crystolon, India and Arkansas stones.

BKF is not the same as Comet, they use different types of acids in their products. BKF is designed for metal.

BKF is not the same as Comet, they use different types of acids in their products. BKF is designed for metal.

- Joined

- Apr 12, 2009

- Messages

- 13,527

Bar Keepers Friend powder, used with water and a scrub brush (toothbrush, etc) works pretty well to dissolve & remove embedded steel swarf from stones. It does rely on chemical action using a light concentration of oxalic acid. The oxalic acid is what dissolves the steel/iron swarf.

- Joined

- Oct 2, 1998

- Messages

- 47,349

The hardness of alumina ceramics is nearly three times that of stainless steel; silicon carbide is more than four times harder than stainless steel. This extreme hardness is one of many unique properties that makes Fine Ceramics "super materials" for modern technology.

Strength - Hardness | Characteristics of Fine Ceramics | Fine ...

global.kyocera.com › fcworld › charact › strong › hard...

Silicon carbide is harder than alumina ceramic and is a superior abrasive for coarser work.

You can abrade the surface of the Spyderco ceramic hone with diamond or silicon carbide, but once that layer wears down, it will be gone.

- Joined

- Feb 2, 2020

- Messages

- 335

I thought that alumina ceramic in Spyderco can not be cut since the stone suppose to last forever. Is Silicon Carbide sandpaper harder them ceramic? If I use 220 grit sandpaper will I make my Spiderco 220 as well? Why people buy several stones if it is possible to condition any Spyderco stone to any grit?

I am sorry - I guess my questions as dull as my knives (at least at the moment before I learned on how to sharpen -LOL) but is it hard for me to do things without understanding how it works

A Spyderco Fine or Ultrafine probably will last forever in use for a person, but nothing lasts forever. What set these apart from other Alumina Ceramics, is the density. These could be polished to almost a glass like surface. They dont seem to wear down to expose new surface and instead slowly load up... Easy to clean out with Bar Keeper's Friend and other products.

Alumina Ceramic, even Spyderco's, can be cut with Silicone Carbide.

Out of the box, a Spyderco Ultrafine is ready to go and flat enough to work up a screaming edge.

If it was absolutely flat, absolutely, if you laid it down on a flat surface such as clean glass, you're not going to be able to simply pick it up. It will suction to the glass and become an epic pain in the ass if you cant slide it off the edge of the surface.

That's the kind of "flat" that I want.

Like I said, I tried pouring 60 grit Silicon Carbide on glass and rubbing the stone in a circular motion. This was uncomfortably loud to the point where it created conflict in my house. "I'm almost done!" ...Nope. The stone is tough as nails and I ended up dishing the glass and convexing the stone, just a little.

The best solution for me was to use a sheet of Silicone Carbide sandpaper flat on glass with water poured on top. Like with everything else, including diamond, a lot of pressure needs to be used... make sure the glass is fully supported otherwise it will break.

These Spyderco stones are tough as nails and they will beat up and destroy any abrasive that you use, including diamond plates. For that reason, the sandpaper seems to make the most sense.

Once you get it flat, it becomes easy to modify the surface. If you go too fine and it's not cutting well, you can always reset the surface by revisiting the sandpaper or using moderate to light pressure on a diamond plate. With using plates, you're risking pieces of diamond getting lodged in the ceramic.

It's hard to quantify these in terms of grit, and maybe that's why Spyderco hasn't. I'd like to know the specific grits myself. I have not explored the bottom and top end of what can be achieved, effectively, with a Spyderco stone.

Last edited:

- Joined

- Oct 2, 1998

- Messages

- 47,349

I got it, guys, but still can I use acid? I think acid should do the best job to remove metal completely while not affecting inert ceramics.

I wouldn't, it's overkill imho. But I guess you could assuming all necessary precautions were in place. That said, ceramic cleans up pretty easily via conventional methods.

- Joined

- Apr 12, 2009

- Messages

- 13,527

I got it, guys, but still can I use acid? I think acid should do the best job to remove metal completely while not affecting inert ceramics.

There are many other options that'll work to clean stones more safely. And depending on the 'acid' tried, there's no guarantee it won't do more damage than good.

The mentioned Bar Keeper's Friend is known to be safe and effective for it, for example. And unless the stone has been very neglected for a long period of time, there's little reason to use anything more aggressive. A lightly- or moderately-used stone can generally be cleaned by even simpler means, like scrubbing with dish soap & water, or with Comet/Ajax cleanser & water, and a decent brush.

With the BKF, it can do a lot just by applying a paste of the powder mixed with water to the stone. Let it sit for a minute or two (or longer on ceramic hones), and rinse it off. Sometimes it's not even necessary to scrub it.

On my Smith's ceramic stones I use a drop or two of Dawn dish washing liquid. Then rub it in all over the stone with my finger and then still rubbing, I slowly rinse stone with warm water. Takes about 95+% of the grime out/off the stone. Works very well.

Rich

Rich