-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barmaley's Aggregated Questions Thread

- Thread starter Barmaley

- Start date

No, I "think" it is from the stone rocking just a little from the friction of pushing it across the paper, so there is more downward pressure of the stone onto the sandpaper at the leading edge of where the stone contacts the paper. The reason why this happens is just an educated guess, but there is no guessing in observing what does happen.

- Joined

- Feb 2, 2020

- Messages

- 335

It's best to alternate stroke type and direction while also rotating which direction you're holding the stone.

Sandpaper on glass can wear edges faster than the center, but less so seemingly than loose SC on glass, due to the glass dishing.

I used SC sandpaper on glass to remove the bulk, which was a chore. I then finished on Atoma diamond plates.

Truly flat diamond plates such as Atoma or DMT Dia-Flat (different than DMT sharpening plates) will produce the best results in terms of flatness and speed of cutting.

For me, the whole point of SC Sandpaper on glass was simply is to minimize wear on my Atoma diamond plates. They're not cheap.

The difference in the polish on steel produced by the Spyderco UF with an Atoma 400 grit finish versus the other side with a 1200 grit finish, is virtually indistinguishable to the eye with simple magnification.

The primary difference that's noticeable is the speed at which the Spyderco UF cuts with either finish.

I'd like to experiment with a wider gap in grit finish between each side. Because SC breaks down, that's hard to accomplish with the tools that I currently have.

Sandpaper on glass can wear edges faster than the center, but less so seemingly than loose SC on glass, due to the glass dishing.

I used SC sandpaper on glass to remove the bulk, which was a chore. I then finished on Atoma diamond plates.

Truly flat diamond plates such as Atoma or DMT Dia-Flat (different than DMT sharpening plates) will produce the best results in terms of flatness and speed of cutting.

For me, the whole point of SC Sandpaper on glass was simply is to minimize wear on my Atoma diamond plates. They're not cheap.

The difference in the polish on steel produced by the Spyderco UF with an Atoma 400 grit finish versus the other side with a 1200 grit finish, is virtually indistinguishable to the eye with simple magnification.

The primary difference that's noticeable is the speed at which the Spyderco UF cuts with either finish.

I'd like to experiment with a wider gap in grit finish between each side. Because SC breaks down, that's hard to accomplish with the tools that I currently have.

The difference in the polish on steel produced by the Spyderco UF with an Atoma 400 grit finish versus the other side with a 1200 grit finish, is virtually indistinguishable to the eye with simple magnification.

That's unexpected. The only difference between the Spyderco Fine and Ultra Fine is the finish applied.

- Joined

- Feb 2, 2020

- Messages

- 335

That's unexpected. The only difference between the Spyderco Fine and Ultra Fine is the finish applied.

I think a larger gap than 400-1200 grit might be needed to see more of a contrast.

The inexpensive 140 grit plate that I own leaves deep scratches. I wont use it again. I should maybe buy the Atoma 140, they're know for grit size consistency.

Achieving a higher fish on the UF is easy with SC sandpaper.

For now I'm content with it as-is

My primary sharpening system is a Smith's 6x2 Fine Diamond (not sure of grit) hone mounted on a wood blood. I rarely let a knife get dull enough where I need a rougher surface. I have owned and used this hone for 3 decades and it's still going strong and will put an edge on any knife that will easily cut cash register receipts. Then I strop with white then green.

Thank you guys for advice, great result! BKF cleaner clogged Arkansas stone nicely, it is like new today! The hardest thing was to get BKF, I almost got on a waiting list to get it shipped from UK for a total for just under $30 according to

K

kreisler

link, but fortunately I found that it is readily available in the USA

Next was another discovery: cleaned medium grid Arkansas stone finally made my knife sharp again. It was cutting phone book paper before sharpening on this stone, it cuts paper in the same manner, however it cuts lamb much nicer now. I guess I need to find another test on sharpness instead of paper test: somehow I found that a knife can cut paper but can not cut produce the way I like it.

Another surprise was to find how fast is Arkansas stone. If feels so smooth when you touch the stone but few strokes and you feel sizable burr! And final surprise was that medium Smith's stone and stropping of a paper (my leather strop was ordered but did not arrive yet) made a chef knife pretty sharp. I can guess it will be even sharper if I work it on a fine stone (after I get one)?

Next was another discovery: cleaned medium grid Arkansas stone finally made my knife sharp again. It was cutting phone book paper before sharpening on this stone, it cuts paper in the same manner, however it cuts lamb much nicer now. I guess I need to find another test on sharpness instead of paper test: somehow I found that a knife can cut paper but can not cut produce the way I like it.

Another surprise was to find how fast is Arkansas stone. If feels so smooth when you touch the stone but few strokes and you feel sizable burr! And final surprise was that medium Smith's stone and stropping of a paper (my leather strop was ordered but did not arrive yet) made a chef knife pretty sharp. I can guess it will be even sharper if I work it on a fine stone (after I get one)?

Jason B.

Knifemaker / Craftsman / Service Provider

- Joined

- Jun 13, 2007

- Messages

- 11,196

While this thread has some good advice I feel this situation has been WAY overcomplicated. Clogged Ark stone? put some WD-40, 3-in-1 oil, honing oil or about any oil on a rag and it will wipe almost completely off. It's an OIL STONE... use oil.

Personally, I only use BKF on sintered ceramics and diamond plates and would not recommend it on any other type of stone.

Personally, I only use BKF on sintered ceramics and diamond plates and would not recommend it on any other type of stone.

Are there any problem using BFK on Arkansas stones? Is WD-40 better?Personally, I only use BKF on sintered ceramics and diamond plates and would not recommend it on any other type of stone.

What is the best oil to use on Akr stone? I got mineral oil from a drag store - is it OK? I hope to use food grade oil.

- Joined

- Apr 18, 2020

- Messages

- 92

I think using acid is overkill. All I do is spray them with windex and wipe it off and it cleans it well. If it's more stubborn I might use a toothbrush. Even wd40, breakfree clp, or CRC works too. Heck you can even use water and dawn dish soap. Now that I think of it I use jus about any thing I have in a can on hand Lol! It dosint matter, Baby oil, 3 n 1 whatever. I think this threads a bit over complicated, your stone isint going to crumble to bits

- Joined

- Apr 20, 2018

- Messages

- 4,458

Are there any problem using BFK on Arkansas stones? Is WD-40 better?

What is the best oil to use on Akr stone? I got mineral oil from a drag store - is it OK? I hope to use food grade oil.

The BKF won't hurt anything and you should rarely need it. What I believe

Plain ole mineral oil works just fine.

- Joined

- Oct 30, 2018

- Messages

- 219

I maintain an abrasives reference chart so I've spent time trying to answer that. These stones are so dense I believe that functionally speaking no natural grain size can be given. It is better thought of as a solid material like steel, which also technically has an internal grain structure but in which the macro-structure of teeth on a saw or file determines how it will cut.

This is a micrograph of 99.9% alumina ceramic, not specifically the Spyderco type.

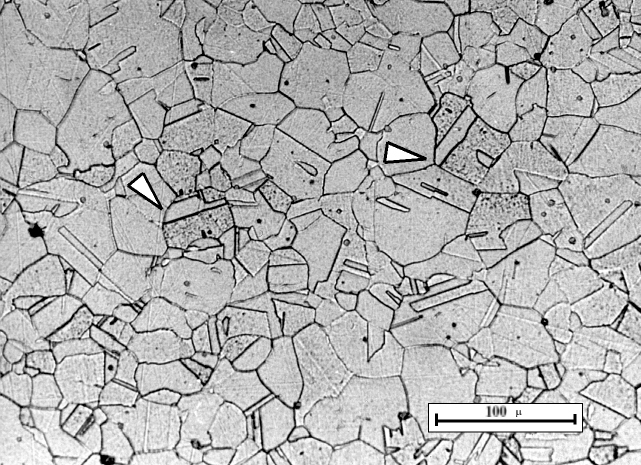

This is a micrograph of stainless steel:

This is totally correct. A sintered ceramic is effectively a powder exposed to heat and (in some circumstances) pressure.

This causes the particles to diffuse into one another creating the grain structure shown in the quoted post. This all happens because of the surface energy of the particles which reduces as the surface/air interface is reduced.

The more packed the green (un sintered) product is, the better the final result regarding % porosity. This all comes down to effective packing of the green product.

Interestingly in times past it was very hard to get a non porous sintered product, bone China is a good example of how this was remedied. Bone ash was added into the clay amongst other things that gave a glass phase in the pottery that filled in the voids or pores. Know as liquid phase sintering.

Vitrified abrasives use a similar process, whereby the abrasive particles are enclosed in a liquid phase.

Long story short, the Spyderco ceramic products are a true sintered product and as such only abrade because of their surface finish and hence have no true grit rating.

- Joined

- Apr 12, 2009

- Messages

- 13,527

I've used BKF for occasional cleaning of a couple of medium (soft) Arkansas stones of mine, with no ill effects on the stone. As Eli mentioned, most of the time, if the stone is oiled in use and then wiped down with fresh oil & a fairly clean rag (microfiber towels are perfect for this), it won't be necessary to use the BKF at all.

Oil is a best friend to Ark stones and other designated 'oil stones', precisely because it keeps the stone working well so easily, so long as you don't neglect cleaning it (with oil) for too long or use the stones dry.

Oil is a best friend to Ark stones and other designated 'oil stones', precisely because it keeps the stone working well so easily, so long as you don't neglect cleaning it (with oil) for too long or use the stones dry.

Last edited:

Jason B.

Knifemaker / Craftsman / Service Provider

- Joined

- Jun 13, 2007

- Messages

- 11,196

Are there any problem using BFK on Arkansas stones? Is WD-40 better?

What is the best oil to use on Akr stone? I got mineral oil from a drag store - is it OK? I hope to use food grade oil.

Nope, but it is a bit pointless IMO. I use oil on oil stones and the oil also cleans them. If you don't use oil on oil stones then they clog and work even slower than they already are. So, there is no point in using BKF, IMO.

It's like trying to use a Japanese Water stone dry... It needs water to work properly so use water.

As for oil,

I like WD-40 because it is thin and easily found. Thicker oils will float the blade with light pressure so I don't recommend them. And yes, mineral oil is THICK and IMO too thick to be a good honing oil.

- Joined

- Dec 8, 2006

- Messages

- 831

I've used aerosol carburetor cleaner on many types of stones for decades with no negative results. Drys fast and leaves a very clean surface.

With all this in mind I guess we should be able to get another sintered ceramic material like floor tile (my understanding it is just clay baked together under very high temperature which should classify it as a sintered ceramic) and then if we could machine the surface of it with silicon carbide sand paper we should get the same finish as Spyderco stones. Will it work? Did somebody try it?Long story short, the Spyderco ceramic products are a true sintered product and as such only abrade because of their surface finish and hence have no true grit rating.

The first and last picture are my washita stones clogged with 20 years of swarf, dust and dirt. The middle pictures are after cleaning. I tried cleaning them with oil to no avail. I specifically joined this forum to see if there was a way to clean them or just throw away and get new ones. They were not nearly as effective as they used to be. @davemartin gave me great advice. After cleaning with comet the were back to performing like new. Still are a year later.

Last edited:

- Joined

- Oct 30, 2018

- Messages

- 219

The substrate needs to be hard enough to cut the metal, we are talking here about macro roughness. For a simple ceramic like a tile, the metal would simply polish the tile rather than the other way around

B

Barmaley

quoting myself:

CoorsTek sintered alumina of 99%+ purity has a bulk harness of 1440 kgf/mm2 (Knoop), and the individual grains should be harder still at about 2000 kgf/mm2 or Mohs 9. Porcelain only has a bulk hardness of about 600–800 kgf/mm2.

From what I am reading high-kaolin clay is elementally about 30% Al₂O₃ but this is chemically part of hydrous aluminum silicates that are very soft. When firing clay "needle shaped crystals of mullite 3Al₂O₃•2SiO₂ begin to form, giving [it] strength and hardness" which apparently has a hardness of 6 to 7 Mohs or 1070 Vickers. My curiosity is satisfied.

Source: https://ceramicartsnetwork.org/ceramic-recipes/reference/clay-minerals/

CoorsTek sintered alumina of 99%+ purity has a bulk harness of 1440 kgf/mm2 (Knoop), and the individual grains should be harder still at about 2000 kgf/mm2 or Mohs 9. Porcelain only has a bulk hardness of about 600–800 kgf/mm2.