Fred.Rowe

Knifemaker / Craftsman / Service Provider

- Joined

- May 2, 2004

- Messages

- 6,848

I'm not a math wiz, by any means, but I was a surveyor for a dozen years. When considering the merits of convex edges compared with flat edges I put forth this thought.

In surveying, when closing a survey to find the total degrees contained inside the survey, you take the number of angles, minus two times 180, equals the number of degrees contained inside the survey.

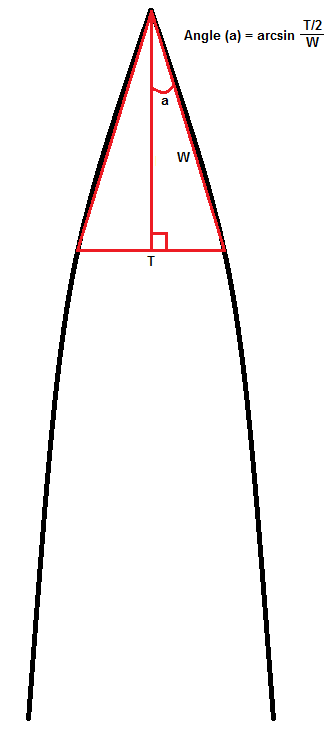

If you apply this to the primary and secondary bevels that make up a knife blade its easy to ascertain the total degrees inside the blades end on profile. In the case of the blade below with its 30 degree inclusive edge, the flat edge itself contains 180 degrees. Number of angles 3 - 2 x 180 = 180

I believe that if you want to compare a convex edge over laid on this 30 degree flat edge it would be more accurate to compare the degree of sharpness between the two edges, first. I think this can be accomplished by adding the degrees contained in the curve of this convex edge and compare the sum to the degrees contained in the flat ground edge. Its a problem of proportion. This is of course is hypothetical, I don't know of a way to measure the actual curve of a convex edge, but I do believe the reasoning is sound.

Once the proportion is found, this number could be used to lengthen the "X" dimension on the flat ground edge which would make the blade thicker at the shoulders, as well as making the flat ground edge angle more obtuse. The angle would increase, it would not be 30 degrees anymore. This would give a more accurate comparison of the two; the convex edge and the flat ground edge. This adjustment along the "X" dimension would result in the two edges being at the same degree of sharp. They should cut the same.

Even though this is a hypothetical problem when I spent some time looking at it in this manner it gave me, what I believe, is a more objective view of this oft compared duo.

What do you think, Fred

In surveying, when closing a survey to find the total degrees contained inside the survey, you take the number of angles, minus two times 180, equals the number of degrees contained inside the survey.

If you apply this to the primary and secondary bevels that make up a knife blade its easy to ascertain the total degrees inside the blades end on profile. In the case of the blade below with its 30 degree inclusive edge, the flat edge itself contains 180 degrees. Number of angles 3 - 2 x 180 = 180

I believe that if you want to compare a convex edge over laid on this 30 degree flat edge it would be more accurate to compare the degree of sharpness between the two edges, first. I think this can be accomplished by adding the degrees contained in the curve of this convex edge and compare the sum to the degrees contained in the flat ground edge. Its a problem of proportion. This is of course is hypothetical, I don't know of a way to measure the actual curve of a convex edge, but I do believe the reasoning is sound.

Once the proportion is found, this number could be used to lengthen the "X" dimension on the flat ground edge which would make the blade thicker at the shoulders, as well as making the flat ground edge angle more obtuse. The angle would increase, it would not be 30 degrees anymore. This would give a more accurate comparison of the two; the convex edge and the flat ground edge. This adjustment along the "X" dimension would result in the two edges being at the same degree of sharp. They should cut the same.

Even though this is a hypothetical problem when I spent some time looking at it in this manner it gave me, what I believe, is a more objective view of this oft compared duo.

What do you think, Fred