chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

You haven't addressed the whole bridging between two joining planes issue.

If you have two planes and grind a third plane between the two planes, you have 3 planes. What is the problem? Only a curve that lies outside (or above) those planes is considered "convex". If the curve falls beneath those planes, then the curve corresponds to some other plane to which it is convex.

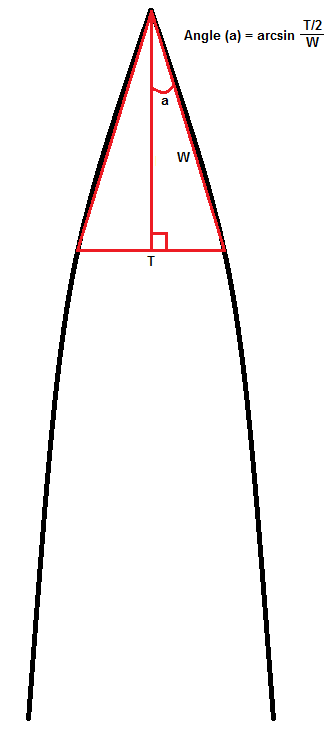

If you grind away the the shoulder where two flat planes meet using a curve to join them (creating a "mid"-bevel or whatever you wish to call it), that curve has a distinct start and end - two points that could be 'bridged' with a straight line falling beneath the curve you created.

Regarding the effect of the convex reducing penetration and increasing wedging, how is that not obvious?

Take as example one of the measurements from the edge of the Gillette razor-blade described, ignoring for now the thickness of the apex: "...a thickness of between 0.96 and 1.16 micrometers measured at a distance of 2 micrometers from the blade tip". The edge-angle that creates is ~14 degrees per side if you measure using straight lines, you'd expect the edge thickness at 1 micrometer from the apex to be ~0.5 microns. But it is a "convex" edge, not a flat V bevel, and what do you get: "a thickness of between 0.61 and 0.71 micrometers measured at a distance of 1 micrometer from the blade tip...".

Which presents a reduction in penetration and an increase in friction via an increase in wedging, the thinner edge or the thicker edge? It should be obvious that the thicker edge requires displacement of more material in order to proceed = greater wedging and reduced penetration. And the convex edge by definition is thicker than the only corresponding flat edge to which it can be compared.

The limit you come up against is how fine you can take your measurements in presenting the angle of the convex edge, but however fine you go, you will always be measuring straight lines that necessarily fall beneath that curve.

Again, it is all contained in the very definition of the word "convex".

EDIT to add:

Here is a butchered version of the sketch in the OP - the blue lines indicate bevels "bridged" by the curved bevel which is "convex" to the bevel beneath it that "bridges" the curve.

Last edited: